JeepParts

My Garage

My Account

Cart

OEM Dodge Sprinter 3500 Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Piston Ring Set found

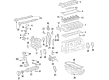

Dodge Sprinter 3500 Piston Rings Part Number: 5138004AA

Dodge Sprinter 3500 Piston Ring Set

Choose OEM Piston Ring Set that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Piston Ring Set follows strict manufacturing steps to lock in quality and fit. If your Dodge Sprinter 3500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Sprinter 3500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Sprinter 3500 Piston Ring Set Parts and Q&A

- Q: How to Service and Repair a Piston Ring Set on Dodge Sprinter 3500?A:Don't remove any metal when cleaning and repairing Piston rings which could change the ring spacing and cause problems with seating. Make sure both sides of the piston ring grooves are undamaged. Remove the engine from its stand and place a feeler gauge between the inside of the groove and the ring land, until the ring moves freely in the groove. After that, set the ring inside the cylinder bore and use a turning motion to push it down until very close to the lowest part of its movement, checking the ring gap at its ends with a feeler gauge. Whether installed up or down, the oil control rings are symmetric; start by setting the oil rail spacer, then insert both side rails without help from a tool. With the piston crown facing the manufacturer's designation, use a ring expander to set each compression ring. Initial gaps for engine parts should have the oil spacer on the piston centerline, the two oil rail gaps separated by 180°, the No. 2 compression ring placed 120° above the top oil rail gap and the No. 1 compression ring 120° above the No. 2.