JeepParts

My Garage

My Account

Cart

OEM Jeep Camshaft Thrust Plate

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Camshaft Thrust Plate found

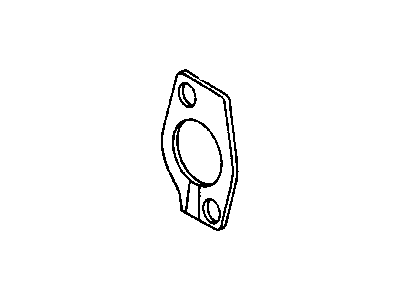

Jeep Thrust Plate Part Number: 4621623

Product Specifications- Other Name: Plate - Camshaft Thrust; Camshaft Thrust Plate; Plate, Camshaft Sprocket Thrust; Plate Camshaft Thrust

Jeep Camshaft Thrust Plate

OEM parts sourced directly from Jeep deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Jeep Camshaft Thrust Plate for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

Jeep Camshaft Thrust Plate enables the camshaft not to walk forward or backward to maintain valve timing sharp and block wear at minimal levels. Jeep cars are glamorous in terms of tough heritage that started in 1945, dominating the rocky paths, and provide the drivers with an open air experience. A contemporary Jeep combines hardcore axles, high ground clearance, and the genius Selec-Terrain knob that changes snow to sand within several seconds. Use of digital dashboards, voice control, over the air updates, and intelligent driver assistants introduce comfort to day to day lives without killing the spirit of adventure. Owners have removable tops and doors and a warm community, and display a Jeep being more than just a mode of transport, but a way of life. The Camshaft Thrust Plate is a small hard steel disc, which is bolted to the block at the cam nose, and clamps the shaft in the right axial position. To install the Jeep Camshaft Thrust Plate, select the right plate and check the cam nose and the block face to see whether they have a scratch or not. Wipe all the surfaces and dry them and put a slight coat of assembly lube. Place the plate on dowels or holes of bolts, flatten it, and then insert new bolts using medium thread locker. Install the Camshaft Thrust Plate, then tighten the two to factory tight and make two rotations with the camshaft, then verify end play by using a dial gauge. Final step will be to install the timing set and restart the engine and ensure that the cam is turning freely and is aligned.