JeepParts

My Garage

My Account

Cart

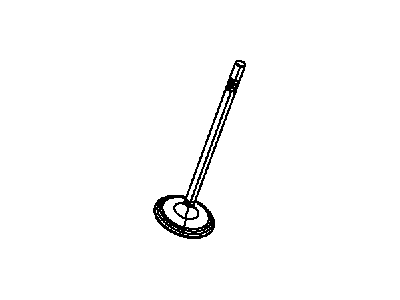

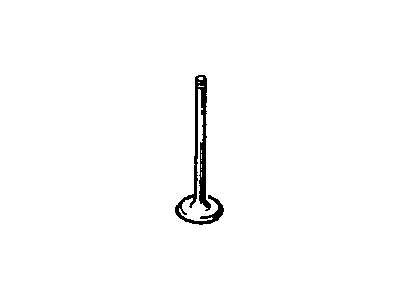

OEM Jeep Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

28 Exhaust Valves found

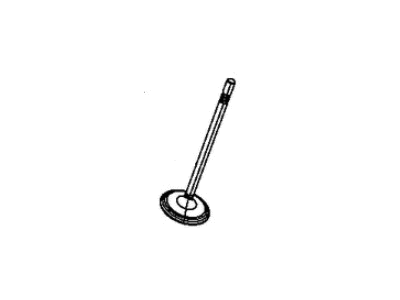

Jeep Exhaust Valve Part Number: 5048022AA

$15.38 MSRP: $22.85You Save: $7.47 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Exhaust; Valve Exhaust Standard

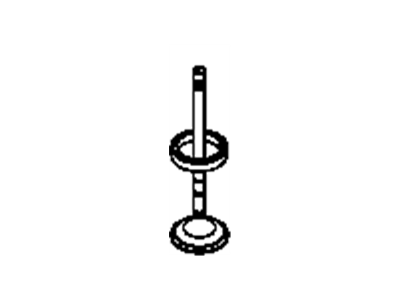

Jeep Valves Part Number: 68147269AA

$55.12 MSRP: $81.05You Save: $25.93 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Exhaust; Intake Valve; Valve Exhaust Standard

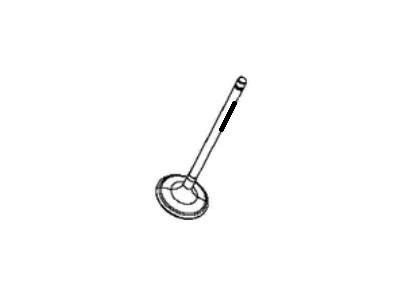

Jeep Exhaust Valve Part Number: 68453300AA

$19.67 MSRP: $28.95You Save: $9.28 (33%)Product Specifications- Other Name: Valve - Engine Exhaust; Intake Valve; Valves; Valve Engine Exhaust

- Replaces: 5047447AA

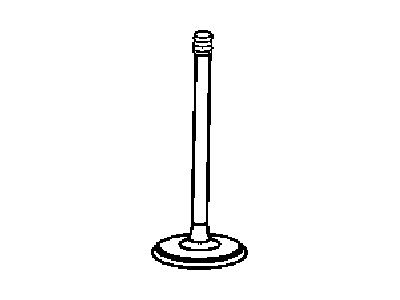

Jeep Exhaust Valve Part Number: 5037373AB

$37.62 MSRP: $55.35You Save: $17.73 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Exhaust; Valve Spring; Valve Springs; Valve Exhaust Standard

Jeep Exhaust Valve Part Number: 5184128AE

$23.14 MSRP: $34.25You Save: $11.11 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Exhaust; Valve Exhaust Standard

- Replaces: 5184128AC, 5184128AD

Jeep Exhaust Valve Part Number: 5048262AA

$38.76 MSRP: $57.05You Save: $18.29 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Engine Exhaust; Intake Valve; Valves; Valve Engine Exhaust

Jeep Valve - Engine Exhaust Part Number: 68306859AB

$15.05 MSRP: $22.00You Save: $6.95 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: ENGINE EXHAUST

Jeep Exhaust Valve Part Number: 53006986

$9.45 MSRP: $13.60You Save: $4.15 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve - Exhaust

Jeep Exhaust Valve Part Number: 68440258AA

$38.87 MSRP: $57.00You Save: $18.13 (32%)Product Specifications- Other Name: Valve - Engine Exhaust; Valve Engine Exhaust

Jeep Exhaust Valve Part Number: 68187410AA

$77.44 MSRP: $119.00You Save: $41.56 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Engine Exhaust; Valve Engine Exhaust

Jeep Exhaust Valve Part Number: 53021916AB

$32.66 MSRP: $47.85You Save: $15.19 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Exhaust; Valve Springs; Valves; Valve Exhaust Standard

- Replaces: 53021644AB

Jeep Exhaust Valve Part Number: 4781029AB

Product Specifications- Other Name: Valve - Exhaust; Valves; Valve Exhaust Standard

Jeep Exhaust Valve Part Number: 53020748

Product Specifications- Other Name: Valve - Exhaust; Intake Valve; Valves; Valve Exhaust Standard

Jeep Valves Part Number: 5142764AA

Product Specifications- Other Name: Valve - Engine Exhaust; Intake Valve; Valve Engine Exhaust

- Replaces: 5066769AA

Jeep Exhaust Valve Part Number: 5175397AA

Product Specifications- Other Name: Valve - Exhaust; Intake Valve; Valves; Valve Exhaust Standard

Jeep Exhaust Valve Part Number: 53021571AA

Product Specifications- Other Name: Valve - Exhaust; Intake Valve; Valves; Valve Exhaust Standard

Jeep Exhaust Valve Part Number: J3224598

Product Specifications- Other Name: Valve; Valve, Exhaust

Jeep Exhaust Valve Part Number: 53006724

Product Specifications- Other Name: Valve - Exhaust; Valve Exhaust Standard; Valve, Exhaust

Jeep Exhaust Valve Part Number: 53010513AA

Product Specifications- Other Name: Valve - Exhaust; Intake Valve; Valves; Valve Exhaust Standard

Jeep Exhaust Valve Part Number: 53021644AC

Product Specifications- Other Name: Valve - Exhaust; Intake Valve; Valves; Valve Exhaust Standard

| Page 1 of 2 |Next >

1-20 of 28 Results

Jeep Exhaust Valve

OEM parts sourced directly from Jeep deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Jeep Exhaust Valve for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

Jeep Exhaust Valve forces the burnt-out gases out in a short time and the engine breathes to retain its punch. Jeep lives on no-nonsense tough guy, a creation of the grit of war and fine-tuned to weekend mud pits, and as a result, every single ride is like it is cliff-top, snowdrift, cross river, city potholes and beyond pavement. Jeep shapes embrace open air, removable panels that make even boring school runs breezy, doors can be packed away in minutes, roof can be packed in seconds. Jeep seatbelts turn Selec-Terrain on and off, and change between sand and snow in a few seconds, digital gauges clap on their behalf. Jeep loads voice, over-the-air customizations, and an enthusiastic owning community that prefers campfire tales to showroom gloss and soulless specifications. The Exhaust Valve is opened at the precise crank angles in the cylinder head, empties the combustion residue that is hot, which closes the Exhaust Valve to trap compression during the next power stroke, maximizing the torque, and scissors off combusted fuel. Accuracy of the Exhaust Valve is important. Rough idle, misfires and bad mileage will become apparent quicker than a dashboard light when it is becoming worn or warped. Information Company relates to fresh Exhaust Valve that will bring a clear flow, revs straight, and keep the whole lineup running tougher crawling over rocks or commuting over downtown.

Jeep Exhaust Valve Parts and Q&A

- Q: How to Remove and Replace Exhaust Valve and Intake Valves on Jeep Grand Cherokee?A:Before you can take out and change the valve, the cylinder heads have to be taken off. You should begin by taking the cylinder head covers off and then follow by removing the rocker arms and the lash adjusters. Following this, remove both of the camshaft bearing caps and then the camshaft. Place Tool C-3422-B or C-3422-C Valve Spring Compressor on the valve, adding Tool 8519 Adapter if required, then use a tapping motion on the top of the valve spring to make the spring retainer locks easier to release. Take out the two halves of the spring retainer lock distrusting the valve spring compressor, as the valve spring may still have a lot of tension. When you remove the spring compressor, carefully get the retainer and spring out, look for burrs in the keeper grooves, remove them if present and then take out the valve from the cylinder head. Because intake and exhaust have the same type of valve stem seal, take it out and mark the valve for correct positioning while you keep track of which camshaft it came from. Springs on the valves should be tested and examined for reuse every time valve removal occurs. Check the condition of the valve springs and with Tool C-647, bring the 40.12 mm mark against the surface and pull on the torque wrench until you get a ping. The spring load is the multiplied by two from the reading. Look up the height and allowable tension for the assembly and use replacement springs if the others do not fit these specifications.

- Q: How to Remove and Replace Exhaust Valve and Intake Valves on Jeep Wrangler?A:Before taking out and putting in a valve, apply clean engine oil to the valve stems and insert those into the cylinder head. After that, put the valve spring seat onto the head, along with seals on all of the valve stems and above the valve guides. After that, add the valve springs and valve retainers, making sure that the springs are installed exactly right.