JeepParts

My Garage

My Account

Cart

OEM 2000 Dodge Intrepid Timing Chain

Engine Timing Chain- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Timing Chains found

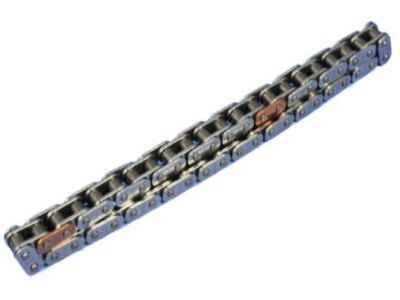

2000 Dodge Intrepid Timing Chain Part Number: 4663674AD

$34.78 MSRP: $57.20You Save: $22.42 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Chain - Timing Secondary; Engine Timing Chain; Chain; Chain Timing Secondary; Chain Timing

- Replaces: 4663674, 4663674AC

- Item Weight: 0.90 Pounds

- Item Dimensions: 9.4 x 5.1 x 1.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4663674AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

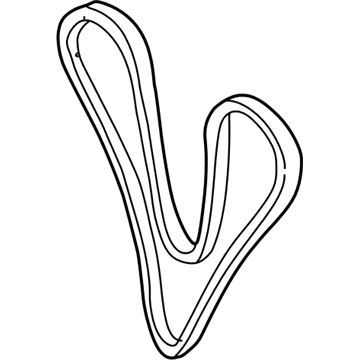

2000 Dodge Intrepid Timing Belt Part Number: 4663635

$141.63 MSRP: $209.00You Save: $67.37 (33%)Product Specifications- Other Name: Chain - Timing; Engine Timing Chain; Timing Chain; Chain Timing

- Item Weight: 4.70 Pounds

- Item Dimensions: 23.0 x 5.3 x 1.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4663635

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Intrepid Timing Chain Parts and Q&A

- Q: How to Service and Repair a Timing Chain on 2000 Dodge Intrepid?A: Service the timing chain by first disconnecting the upper intake manifold, removing the cylinder head covers, crankshaft damper and timing chain cover. Before every timing check, always turn the crankshaft to move the engine and safeguard the valves and pistons. Move the crankshaft sprocket until its timing mark is matched to the mark on the oil pump housing at 60°. Fuel injection is controlled from the #1 cylinder in ATDC. If the timing chain is taken out with the cylinder heads still there, remember not to rotate either the camshafts or the crankshaft unless you first locate where the crank is by using a timing light. Take away the timing chain tensioner that is on the cylinder head on the right, take out the camshaft position sensor from the cylinder head on the left and remove the access plug for the chain guide from the same area. Before pulling out camshaft sprocket bolts, notice that the camshafts will turn clockwise. First, check that the camshaft sprocket is suitable and after removing its bolts, remove the camshaft damper and sprocket. After that, remove the left side camshaft sprocket screws and the sprocket, then unscrew the lower chain guide and tensioner arm and end by pulling out the primary timing chain. Check every sprocket and chain guide and restore them if they are worn out. If these short chain guides are being replaced, fit both sides and tighten the attachments to 28 Nm (250 in. lbs.). Put the crankshaft shaft timing mark in line with the oil pump housing mark and grease the timing chain and its guides with automobile oil before installing. Set the primary sprocket over the chain, with the timing mark between the two plated timing connectors and let the chain slide though the left cylinder. Hold the left side camshaft sprocket loosely over the end of the camshaft hub, lining up the timing marked link next to the crankshaft sprocket mark. Start by setting the primary chain on the water pump drive sprocket, make sure the right camshaft sprocket mark lines up with the link on the timing chain and put it loosely on the camshaft hub. Check that every plated link on the chain fits the sprocket's timing marks, after which you should install the left side lower chain guide and tensioner arm, tightening all the bolts to 28 Nm (250 in. lbs.). Check the oil ring inside the chain guide plug before you start and change it if needed. Tighten the chain guide access plug on to the left side cylinder head using 20 Nm (15 ft. lbs.). Pour oil from the tensioner by placing the ball in Special Tool 8186 and you always apply pressure gradually to it. Put the cylinder plunger into the deeper hole of Special Tool 8186 and then pull down until the tensioner is set. You must ensure the tensioner is reset, ensuring it rests against the top of Special Tool 8186, to prevent jamming stirring during fastening. Attach the reset chain tensioner in the right cylinder head, place the tensioner retaining plate in position and tighten the bolts until each reaches 12 Nm (105 in. lbs.). Start on the right cylinder bank and with a 3/8" extension, insert a breaker bar into the intake camshaft drive hub and rotate the camshaft so that the camshaft sprocket and damper look aligned below. Attach the sprocket bolts and turn them until they reach 28 Nm (250 in. lbs.) of tightness. Place a 3/8" square drive extension onto a breaker bar and use it to turn the left side camshaft all the way to where the sprocket bolts can be fitted and tighten them to 28 Nm (250 in. lbs.). If the timing chain needs it, rotate the engine a little clockwise to remove slack. Insert a flat tool into the tensioner arm's opening and push the tensioner arm towards the tensioner slightly until the tensioner locks, then release it. After that, attach the timing chain cover, crankshaft damper and cylinder head covers, restore power to the cam sensor and place the upper intake manifold. An initial engine noise will occur after you reset the tensioner, but it should go away in 5 to 10 seconds.