JeepParts

My Garage

My Account

Cart

OEM 2000 Dodge Neon Crankshaft Seal

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Crankshaft Seals found

2000 Dodge Neon Rear Main Seal Part Number: 4621939AB

$27.24 MSRP: $40.20You Save: $12.96 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Seal - Rear Main Crankshaft; Engine Crankshaft Seal, Rear; Rear Seal; Seal Rear Main Crankshaft Serviced With Retainer [04663625]; Crankshaft Seal

- Position: Rear

- Item Weight: 0.50 Pounds

- Item Dimensions: 0.7 x 4.6 x 4.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4621939AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Neon Front Crank Seal Part Number: 4667198

$16.36 MSRP: $23.75You Save: $7.39 (32%)Product Specifications- Other Name: Seal - Front Main Crankshaft; Engine Crankshaft Seal, Front; Timing Cover Gasket; Timing Cover Seal; Front Seal; Crankshaft Front Oil Seal; Engine Crankshaft Seal.

- Position: Front

- Item Weight: 0.40 Pounds

- Item Dimensions: 0.6 x 2.0 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4667198

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Neon Timing Cover Gasket Part Number: 4667340AB

Product Specifications- Other Name: Seal - Timing Belt Cover; Engine Timing Cover Gasket; Timing Cover Seal; Front Cover Gasket; Inner Gasket; Seal

- Replaces: 4667340

- Item Weight: 0.40 Pounds

- Item Dimensions: 3.2 x 2.4 x 0.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4667340AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

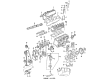

2000 Dodge Neon Crankshaft Seal Parts and Q&A

- Q: How to Service and Repair a Crankshaft Seal on 2000 Dodge Neon?A: The first step to service or repair the crankshaft main bearing seal is to take out the transaxle and drive plate. Pry the seal away by placing the 3/16 flat bladed screwdriver between the dust lip and the metal crankshaft seal where it meets, making sure the blade does not catch the seal itself but only the chamfer. Run a piece of 400 grit sandpaper across the burrs or scratches on the crankshaft to stop the seal from being damaged during installation. It is not necessary to lubricate the new seal during installation. Put the pilot tool, Special Tool 6926-1, on the crankshaft and then position the seal, with the words THIS SIDE OUT and the inner side of the lip from the seal facing you. Carefully avoid placing the seal in the engine block so that it is not past flush, otherwise there may be an oil problem. With Special Tool 6926-2, push C-4171 to fasten the seal into position, so it touches the bottom of the tool. Slide the drive plate back in using adhesive on the threads, tighten the bolts to 95 Nm (70 ft. lbs.) and mount the transaxle again.