JeepParts

My Garage

My Account

Cart

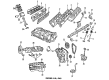

OEM 2001 Dodge Dakota Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Pistons found

2001 Dodge Dakota Piston Part Number: 68067503AA

$32.19 MSRP: $185.00You Save: $152.81 (83%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 4778865AB, 4778861AB

- Item Weight: 4.00 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68067503AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Dakota Piston Part Number: 4798329AC

$138.85 MSRP: $200.00You Save: $61.15 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Pin And Rod; Piston Pin And Rod

- Item Weight: 3.20 Pounds

- Item Dimensions: 13.8 x 6.2 x 4.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4798329AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Dakota Piston Part Number: 68233351AA

Product Specifications- Replaces: 5012362AF, 5012362AE, 5012362AC, 5012362AD

- Item Weight: 3.00 Pounds

- Item Dimensions: 10.5 x 6.3 x 6.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68233351AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Dakota Piston Part Number: 68067510AA

Product Specifications- Replaces: 4778872AD, 4778876AB, 4778876AD, 4778876, 4778874AD, 4778876AC

- Item Weight: 3.60 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68067510AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Dakota Piston Part Number: 68067509AA

Product Specifications- Replaces: 4778871AC, 4778875AD, 4778875AC, 4778873AB, 4778873AC, 4778871AB, 4778871AD, 4778873AD

- Item Weight: 4.00 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68067509AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Dakota Piston Part Number: 68067504AA

Product Specifications- Replaces: 4778862AB, 4778864AB

- Item Weight: 4.00 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68067504AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Dakota Piston Part Number: 4798332AC

Product Specifications- Other Name: Piston Pin And Rod; Piston Pin And Rod

- Replaces: 4798333AC, 4798331AC, 4798333AB, 4798330AB, 4798330AC

- Item Weight: 3.20 Pounds

- Item Dimensions: 13.3 x 6.1 x 4.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4798332AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Dakota Piston Parts and Q&A

- Q: How to Safely Remove and Replace a Piston in an Engine on 2001 Dodge Dakota?A: To swap the piston, first uncover the engine cylinder head, take out the rocker arms, then remove both bridges and pivots, the push rods and finally the engine cylinder head. Make each piston approach the bottom of the forced stroke and between each, ridge ream the top of the cylinder walls to remove any ridges, gathering the debris with the protective cloth. Raise the vehicle, drain the engine oil and then take out the oil pan and gasket. After that, remove the connecting rod bearing caps and inserts, using the cylinder bore to label them, because the connecting rod caps and rods have letters stamped together on them. Adjust the vehicle until it is about 2 feet up from the flooring, rubbers hose should stop the connecting rod bolts from hurting the crankshaft journals or cylinder walls. Let your assistant push on the piston and connecting rod assembly so it goes all the way up through the cylinder bores. When installing the cylinders, clean them with water and put a very thin film of clean oil over them with a lint-free cloth. When removing the piston rings, replace them on the pistons and then cover them with engine oil so that the connecting rod bolts cannot scratch the crankshaft journals or walls of the cylinder. Install the connecting rod and piston assemblies into the cylinder bores above by compressing the piston ring with a piston ring compressor and have the piston's arrow indicate forward of the engine as you install them. Raise the engine again and set each bearing insert into the journal until the suggested clearance is reached, using the bearing inserts suggested in the Connecting Rod Bearing Fitting Chart. The rod journal is distinguished by a paint mark on the next cheek to the flange end of the crankshaft, with color codes showing the different journal sizes in the chart also. If needed, standard size bearings may go with undersized inserts of any thickness to decrease clearance to 0.013 mm (0.0005 inch). Do not mix up bearing caps, because on each connecting rod and bearing cap is the cylinder number which is read off the machined surface located next to the oil squirt hole centered on the camshaft face of the cylinder block. Attach the connecting rod bearing caps and inserts to their correct spots, so the oil squirt holes in the rods are toward the camshaft and the arrows on the pistons point toward the front end of the engine. Replace the oil pan and the gasket, return the vehicle to ground and fit the engine cylinder head, push rods, rocker arms, bridges, pivots and engine cylinder head cover. Pour engine oil into the crankcase last.