JeepParts

My Garage

My Account

Cart

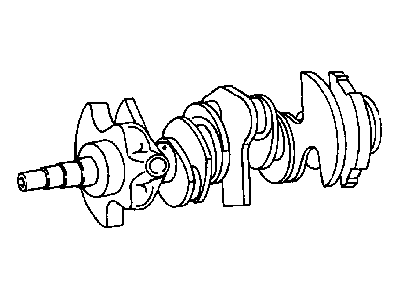

OEM 2002 Chrysler 300M Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

2002 Chrysler 300M Crankshaft Part Number: 4792692AB

Product Specifications- Other Name: Crankshft

- Replaces: 4792692AC, 4792177, 4792692AA

- Item Weight: 56.60 Pounds

- Item Dimensions: 22.3 x 8.4 x 7.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4792692AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler 300M Crankshaft Parts and Q&A

- Q: How to Remove and Install a Crankshaft in an Engine on 2002 Chrysler 300M?A: To get rid of the crankshaft, take the engine out of the chassis, remove the oil pan, oil pickup tube, crankshaft vibration damper, idler pulley for the accessory drive belt, front lower timing belt cover, front main timing belt cover and front left side timing belt cover. Then, you should remove the timing belt tensioner and its belt and the crankshaft sprocket afterward. Next, pull out the dowel pin from the crankshaft, then untap the oil pump assembly, the crankshaft lower oil seal retainer, the connecting rod bearing caps (being sure to keep them in order) and main bearing caps. In the end, take out the crankshaft from the cylinder block. Always make sure to check the journals for abnormal wear, taper or scoring before fitting the crankshaft, so that the taper limits or out-of-round do not pass 0.015 mm (0.0006 inch) and make certain journal grinding does not go over 0.305 mm (0.012 inch) over the standard journal diameter. Once you've finished grinding, ensure that every passage is cleaned and that all the crankshaft holes' rough edges are removed in the same direction the forged steel crankshaft will rotate. Installation begins with putting in the main crankshaft bearings, ready the cylinder block with the crankshaft moved to the front so the front thrust washer is lubricated and fitted and then the crankshaft is pushed back to install the rear thrust washer. Make sure to clean the engine oil and then add a small amount to the lower main bearings before you attach the cap bolts. Install every main cap and turn the bolts until they are finger-tight with the order in mind: inner main caps first, then windage tray bolts and basis tie bolts lastly. Secure the mitring bolts to 20 Nm and turn them 1/4 turn past that, measure the crankshaft's end float, fit the connecting rods and measure their side clearance, before installing and lubing the windage tray, tightening it to 27 Nm plus 1/4 turn. Reinsert the main cap tie bolts and turn them tight to 28 Nm, then fit the rear crankshaft oil seal retainer and the oil seal, assemble the oil pump, drive dowel pin, crankshaft sprocket, camshaft sprockets, install the timing belt, cover it with the timing belt covers, next, put in the crankshaft vibration damper, idler pulley for the accessory drive belt, oil pickup tube bolt, the oil pan and finally, install the engine assembly.