JeepParts

My Garage

My Account

Cart

OEM 2002 Chrysler Sebring Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Pistons found

2002 Chrysler Sebring Vibration Damper Part Number: 5142303AB

$56.55 MSRP: $81.25You Save: $24.70 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston; Piston Pin And Rod

- Replaces: 5142303AA, 5066565AB

- Item Weight: 3.00 Pounds

- Item Dimensions: 5.7 x 4.4 x 12.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5142303AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler Sebring Piston Part Number: MD357068

$45.47 MSRP: $65.35You Save: $19.88 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - Standard; Piston & Pin Assembly Standard

- Item Weight: 1.30 Pounds

- Item Dimensions: 3.8 x 3.8 x 2.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: MD357068

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler Sebring Piston Part Number: 5018627AD

$316.65 MSRP: $576.00You Save: $259.35 (46%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Pin And Rod; Piston Pin And Rod

- Replaces: 5018627AB, 5018627AA, 5018627AC

- Item Weight: 2.60 Pounds

- Item Dimensions: 13.3 x 5.2 x 4.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5018627AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler Sebring Piston Part Number: MD357067

$89.79 MSRP: $133.00You Save: $43.21 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - Standard; Piston & Pin Assembly Standard; Piston And Pin

- Item Weight: 1.30 Pounds

- Item Dimensions: 3.8 x 3.9 x 2.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: MD357067

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler Sebring Piston Part Number: MD357066

Product Specifications- Other Name: Piston - Standard; Piston & Pin Assembly Standard

- Item Weight: 1.40 Pounds

- Item Dimensions: 3.9 x 3.8 x 2.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: MD357066

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler Sebring Piston Parts and Q&A

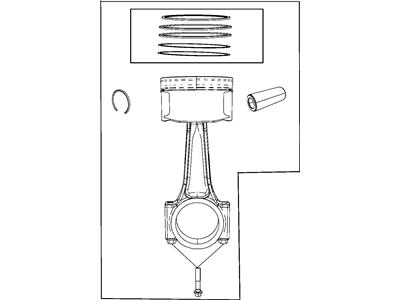

- Q: How to Install and Remove Pistons in an Engine on 2002 Chrysler Sebring?A: Remove the top edge of the cylinders with a good ridge reamer and keep the tops of the pistons covered. You must retrieve the pistons and connecting rods from the top of the block, making sure the crankshaft turns so all the connecting rods are in the middle of their cylinders. Place marks where the connecting rod and bearing caps are supposed to go by using an ink marker or scribe tool, without harming the broken rod and cap faces. Take off the rod cap and fit Special Tool 8189 Connecting Rod Guides into the rod you're removing, making sure not to scratch the crankshaft journals when pulling each piston and rod from the cylinder. After removal, fit the bearing cap on the other end of the rod to prevent anything from happening to it. As the first step in installing, put on the piston rings, make sure the compression ring gaps are not in line and place the oil ring expander ends opposite the rail gaps. Rub engine oil on the piston head and rings, put the ring compressor on top of the piston and tighten with the special tool while holding the piston in place. Set the bearing half so that the hole in it lines up with the hole in the connecting rod, coat the bearing surface with some clean engine oil and equip Special Tools 8189 Connecting Rod Guides into the connecting rod. Look for the arrow and "F" (Front) above the pin boss on the piston-on both sides, both pistons need to point toward the engine's front with the connecting rod oil hole aimed at the block's major thrust side. With the crankshaft slowly rotating, center the connecting rod journal in the cylinder bore, plant the rod and piston and let the rod travel over the shaft journal. In one motion, tap the piston into place with a hammer and simultaneously guide the connecting rod so it ends up on the connecting rod journal. Apply engine oil to both the rod bolts and sticking surface, place the appropriate connecting rod cap and bearing on and screw on the bolts to 27 Nm, turning them another 1/8 turn.