JeepParts

My Garage

My Account

Cart

OEM 2003 Dodge Ram 3500 Wheel Hub

Wheel Axle Hub- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Wheel Hubs found

2003 Dodge Ram 3500 Wheel Bearing, Rear Outer Part Number: 5086774AA

$34.65 MSRP: $51.35You Save: $16.70 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing - Wheel; Wheel Bearing, Rear Inner, Rear Outer; Axle Bearing; Bearings; Wheel Bearings; Inner Bearing; Bearing Wheel Inner; Bearing Wheel

- Position: Rear Outer

- Replaced by: 68645813AA

- Item Weight: 1.50 Pounds

- Item Dimensions: 1.1 x 4.3 x 4.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5086774AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Ram 3500 Wheel Bearing, Rear Inner Part Number: 5086772AA

$87.24 MSRP: $129.00You Save: $41.76 (33%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing - Wheel; Wheel Bearing, Rear Inner, Rear Outer; Axle Bearing; Bearings; Wheel Bearings; Outer Bearing; Bearing Wheel Outer; Bearing Wheel

- Position: Rear Inner

- Item Weight: 1.10 Pounds

- Item Dimensions: 1.6 x 3.6 x 3.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5086772AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

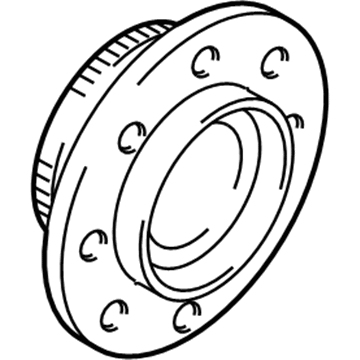

2003 Dodge Ram 3500 Hub & Bearing, Front Part Number: 52010206AD

$709.90 MSRP: $1045.00You Save: $335.10 (33%)Product Specifications- Other Name: Hub - Brake; Front Wheel Bearing and Hub Assembly; Wheel Hub Repair Kit; Axle Bearing.; Front Hub & Bearing; Hub And Bearing Brake Front; Wheel Bearing and Hub Assembly; Wheel Bearing; Hub Assembly

- Position: Front

- Replaces: 52010206AC, 52010206AB

- Item Weight: 17.50 Pounds

- Item Dimensions: 10.6 x 10.7 x 5.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52010206AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

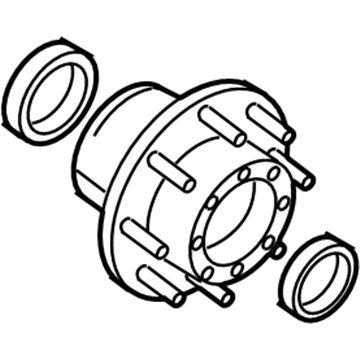

2003 Dodge Ram 3500 Hub & Bearing Part Number: 5083727AA

Product Specifications- Other Name: Wheel; Wheel Hub Repair Kit; Wheel Bearing; Wheel Hub; Front Hub & Bearing; Hub Assembly Wheel Rear; Hub Wheel

- Item Weight: 30.50 Pounds

- Item Dimensions: 9.7 x 9.4 x 9.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5083727AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Ram 3500 Hub & Bearing Part Number: 52121158AA

Product Specifications- Other Name: Hub - Wheel; Wheel Hub Repair Kit; Wheel Bearing; Wheel Hub; Front Hub & Bearing; Hub Assembly Wheel Rear; Hub Wheel

- Item Weight: 37.40 Pounds

- Item Dimensions: 19.4 x 19.2 x 11.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52121158AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Ram 3500 Hub & Bearing Part Number: 5015282AA

Product Specifications- Other Name: Hub - Brake; Wheel Bearing and Hub Assembly; Wheel Hub Repair Kit; Axle Bearing.; Front Hub & Bearing; Hub And Bearing Brake

- Item Weight: 20.40 Pounds

- Item Dimensions: 9.5 x 9.5 x 9.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5015282AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Ram 3500 Wheel Hub Parts and Q&A

- Q: How to Maintain and Repair a Wheel Hub with Link/Coil Suspension on 2003 Dodge Ram 3500?A: In order to service and repair the wheel hub on a vehicle using link or coil suspension, first prop up the vehicle, then take out the wheel and tire assembly. After that, undo the hub extension mounting nuts and, if your car has them, separate the extension from the rotor, then take off the brake caliper. When that's done, take out the cotter pin and hub nut from the axle shaft and separate the ABS wheel speed sensor connection from the area near the hood and connect it to the frame and steering knuckle if available. Each bolt holding the hub/bearing should be backed off by 1/4 inch and then tap those bolts to loosen the hub/bearing from the knuckle. First, take out the bolts that hold the hub/bearing mounting on the steering knuckle, then take out the hub/bearing, the rotor and the brake shield, together with their spacer. To disconnect the rotor from the hub, press out the studs and remove any wheel speed sensor attached to the hub. Attach the wheel speed sensor wheel speed sensor to the hub bearing if you have one, then slide the rotor onto the bearing/hub and insert the back of the wheel studs/hub extension studs into the hub bearing flange. Spread anti-seize compound over the front drive splines, after which you insert the middle rotor bolts into the steering knuckle from behind so they come out through the front. Install the hub spacer and brake shield on the bolts you just set in the knuckle and put the brake shield on the hub bearing only if you have a wheel speed sensor. Glide the rotor hub along the drive shaft and start pushing the shaft into the rotor hub's splines, with the wheel speed sensor wire located at the top of the knuckle if it is present. Put the bolt holes in the hub bearing flange over the bolts in the knuckle, thread the first set of bolts into the bearing flange and tighten all the remaining bolts and the hub/bearing bolts to 202 Nm (149 ft. lbs.). Put the washer and nut onto the axle, tightening it to a first torque of 179 Nm (132 ft. lbs.), after that, turn the axle 5 to 10 times until the hub bearing is seated, then tighten the nut to 356 Nm (263 ft. lbs.). Bring the axle nut to the subsequent hole for the cotter pin and add a new pin to it, then install the caliper. Screw the sensor wire to the steering knuckle and frame and then set the wheel speed sensor wire on the vehicle's engine bay. After that, secure the wheel and tire assemblies. Remove the support, then lower your vehicle, braking several times while motionless to set all the brake parts and do not drive until the brake pedal feels solid.