JeepParts

My Garage

My Account

Cart

OEM 2005 Chrysler Sebring Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Crankshafts found

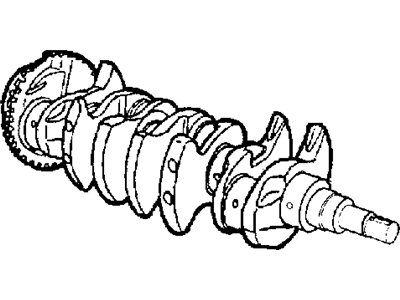

2005 Chrysler Sebring Crankshaft Part Number: 4781643AA

$539.13 MSRP: $818.00You Save: $278.87 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft Includes Target Ring And Screw

- Item Weight: 47.80 Pounds

- Item Dimensions: 24.5 x 8.8 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4781643AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

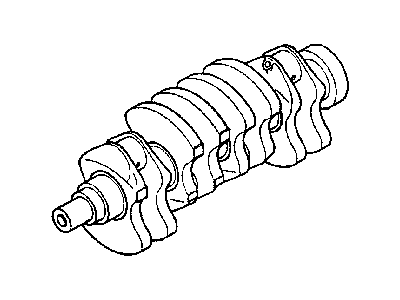

2005 Chrysler Sebring Crankshaft Part Number: MD346026

$698.27 MSRP: $984.00You Save: $285.73 (30%)Ships in 1-2 Business DaysProduct Specifications- Item Weight: 40.40 Pounds

- Item Dimensions: 21.9 x 7.9 x 6.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: MD346026

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

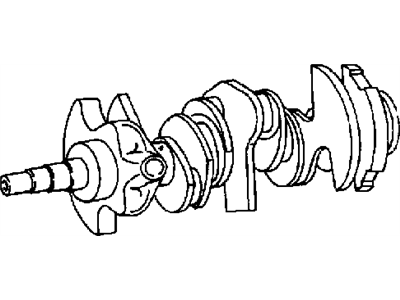

2005 Chrysler Sebring Crankshaft Part Number: 4663638

$1000.64 MSRP: $1485.00You Save: $484.36 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft

- Item Weight: 51.50 Pounds

- Item Dimensions: 22.5 x 8.0 x 7.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4663638

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Chrysler Sebring Crankshaft Parts and Q&A

- Q: How to Remove and Replace a Crankshaft on 2005 Chrysler Sebring?A: To swap the crankshaft, it is necessary to take out the whole engine and separate it from the transaxle. After that, the drive plate/flex plate and oil seal on the crankshaft's backside should be removed and the engine placed on a repair stand. Empty the engine oil and remove the oil filter, after that take apart the crankshaft vibration damper, engine mount support bracket, front timing belt covers, timing belts, rear timing belt cover, oil pan, oil pump pick-up tube, crankshaft sprocket and oil pump. Take out the balance shafts, the housing and the crankshaft position sensor. In case piston or connecting rod replacement is needed, the cylinder head will need to be removed. Identify each rod by coloring the very top of its cap with an indelible marker or paint, instead of writing the number with a stamp or punch. Get rid of all connecting rod bolts and caps, making certain not to harm the fracture rod and cap and never reuse those bolts. First, remove each bed plate bolt from the engine block and then gently tap the bed plate loose by twisting the opposite edge so you don't twist one area more than another. To avoid harm to the dowel pins and thrust bearing, the bed plate should come off evenly in every direction. Take care when removing the crankshaft to prevent harm to the main bearings or journals and then drop out and discard the target ring mounting screws and target ring. Check the crankshaft journals for signs of too much wear, taper or scoring, so that the allowance for taper or out of roundness is not more than 0.025 mm (0.001 inch) and crankshaft grinding does not exceed 0.305 mm (0.012 inch) under the standard diameter. We should never grind the thrust faces on the No. 3 main bearing and be sure not to nick the fillet of the crank pin or of the bearing. After grinding, take off the rough edges from the oil holes and clean the passages, making sure the final polish on a nodular cast iron crankshaft is going in the same direction as regular rotation. The crankshaft is installed by supporting it with five main bearings and all upper bearings in the crankcase have oil-filled grooves and holes, as do all lower bearing shells except the thrust bearing half. Make sure both holes in the bearing upper shells and the engine block aligned with each other. Before the crankshaft is shipped, it has to be balanced while the target ring is in place. Clean the crankshaft and target ring with Mopar(R) brake parts cleaner, dry them afterwards with compressed air and after that add the new mounting screws finger tight, beginning with #1, checking that they are engaged before doing the others. Use a T30 torx bit and tighten each mounting screw to 13 Nm (110 inch lbs.), applying the correct sequence given in the manual. Before putting the crankshaft in the engine, coat the bearings and journals with Mopar(R) Bed Plate Sealant and the bed plate with Bed Plate Sealant only. Slide the lower main bearings into the main bearing cap/bed plate, so the bearing tabs are properly seated and adding oil. First, lay 1.5 to 2.0 mm (0.059 to 0.078 inch) of Mopar(R) Bed Plate Sealant on the bed plate and follow by fitting the main bearing/bed plate into the engine block. Apply clean engine oil to the bolts and assemble the main bearing bed to the engine block, still leaving all the bolts slightly loose so the bed plate touches the cylinder block. Ensure the crankshaft is properly aligned with the gearbox by rotating it, letting number 4 piston be at Tdc, pushing the crankshaft back to its limit, then moving it forward to the other limit; now wedge a suitable item between the rear of the block and the crankshaft counterweight. Secure all bolts step by step to 41 Nm (30 ft lbs.), remove the wedge and tighten them all back up using the same torque value. Starting with the bolts on the main bearing bed plate, tighten each set as described above: primary to 28 Nm (250 inch lbs.), then the first set to 75 Nm (55 ft. lbs.) and the second set to 28 Nm (250 inch lbs.). Once you put in the main bearing bed plate, measure the torque of the crankshaft, not allowing it to be greater than 5.6 Nm (50 inch lbs.) and make sure there is no more than 0.005 to 0.008 inch of end play. Mount the connecting rod bearings and caps and make sure not to put the old connecting rod bolts back; fasten all connecting rod bolts to 27 Nm (20 ft. lbs.) plus 1/4 turn. Set in the balance shafts and their housing, the oil pump and the oil pump pick-up tube, torquing the fastener to 23 Nm (200 inch lbs.). Stick the oil pan, crankshaft position sensor and cylinder head back in, if they have been taken out. Lastly, place the timing belt rear cover, crankshaft sprocket and timing belt on the engine, as well as the front timing belt covers, bracket for the engine mount support, crankshaft vibration damper, new oil filter and seal on the rear crankshaft and flex plate. Apply Mopar(R) Lock & Seal Adhesive to all bolt threads and tighten everything to 95 Nm (70 ft. lbs.) Attach the transaxle to the engine and fasten its bolts to 101 Nm (75 ft. lbs.) before reinstalling the engine assembly.