JeepParts

My Garage

My Account

Cart

OEM 2005 Dodge Neon Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Pistons found

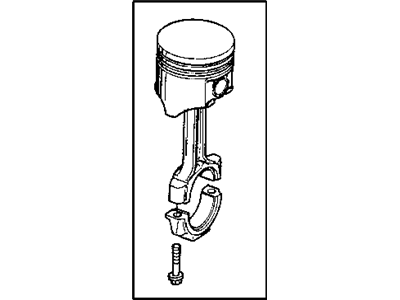

2005 Dodge Neon Piston Part Number: 68067340AA

$92.81 MSRP: $107.00You Save: $14.19 (14%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 5103508AA

- Item Weight: 2.70 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68067340AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

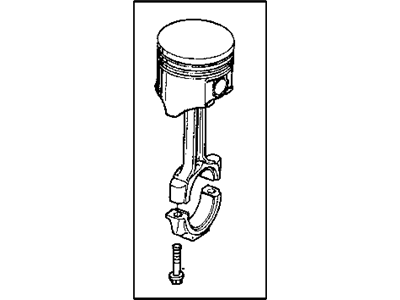

2005 Dodge Neon Piston Part Number: 4884247AD

Product Specifications- Other Name: Piston Pin And Rod; Piston Pin And Rod

- Replaces: 4884247AC

- Item Weight: 3.10 Pounds

- Item Dimensions: 13.7 x 6.2 x 4.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4884247AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Dodge Neon Piston Parts and Q&A

- Q: How to Remove and Replace a Piston and Connecting Rod on 2005 Dodge Neon?A: Before taking out and replacing the piston and connecting rod, remove the cylinder head and the oil pan. After using a ridge reamer to clear the cylinder head above its bores, let each piston sit in the bore it was in and mark it with the number of the cylinder it was removed from. Write the cylinder number on each rod cap with a suitable marker. You will notice that the pistons have a mark indicating if they are H for heavy or L for light weight, as well as an S if they are service pistons. All service assemblies should be the same weight class and their weight designations should face the side of the engine with the timing belt. With the crankshaft turned, lower each piston to its abstract rod and boost and loosen and remove every attaching pin and lift, ensuring you don't harm the bolts and surface found on the fracture rods and cap. After attaching Special Tool 8189 and installing its rod guides, push both parts of each assembly up to remove them from the cylinders. After the guides are removed, fit the side cap onto the rod again and go through each assembly the same way before removing the piston rings. Always stagger the gaps between the compression rings as you put them on the pistons, so they don't line up with the gap in the oil ring rail. Make sure the parts you're using are all butted and the gapping of the rails is correct before pressing the oil ring expander section into the ring compressor. Drop the head and rings in a bath of clean engine oil, use the ring compressor to cover the piston and check that the rings do not change position. The engine bay should show the L or H label next to the front of the engine. Spin the crankshaft until the connecting rod journal is centered in the cylinder bore, apply clean engine oil to the journal and fix the upper bearing piece to the rod. With Special Tool 8189, direct the rod and piston towards the bore, tapping the piston carefully as the rod gets into place. After removing the guides, fit the bottom half of the bearing into the connecting rod cap and place new bolts to hold it in place. Don't forget to cover the bolts with clean engine oil. Adjust each bolt so it's tightened by hand and then, using a torque wrench, set each bolt to 27 Nm and increase it by approximately 1/4 turn without the wrench. Use a feeler gauge to check the connecting rod side clearance and after that, install the cylinder head and oil pan.