JeepParts

My Garage

My Account

Cart

OEM 2005 Dodge Ram 3500 Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Pistons found

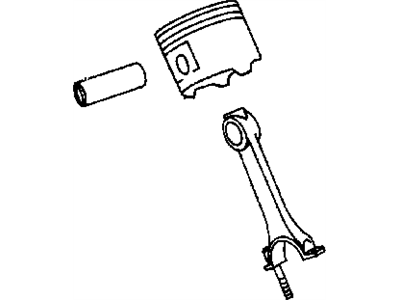

2005 Dodge Ram 3500 Piston Part Number: 5086011AB

Product Specifications- Other Name: Piston Pin And Rod; Piston Pin And Rod

- Item Weight: 3.10 Pounds

- Item Dimensions: 12.7 x 5.6 x 4.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5086011AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Dodge Ram 3500 Piston Part Number: 5139059AA

Product Specifications- Other Name: Piston - Diesel Engine; Piston And Rings Diesel Engine Standard Size

- Item Weight: 3.20 Pounds

- Item Dimensions: 5.6 x 5.5 x 5.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5139059AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Dodge Ram 3500 Piston Part Number: 5086010AB

Product Specifications- Other Name: Piston Pin And Rod; Piston Pin And Rod See Note; Piston Pin And Rod

- Item Weight: 3.10 Pounds

- Item Dimensions: 12.9 x 5.5 x 4.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5086010AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Dodge Ram 3500 Piston Parts and Q&A

- Q: How to Replace a Piston and Its Connecting Rod on 2005 Dodge Ram 3500?A: Unplug the battery cables and then take out the cylinder head, suction tube, oil pan and any bolts attaching the piston to the block stiffener, to replace the piston and connecting rod. Use Miller Tool 7471-B to turn the crankshaft until the pistons are all below the top dead center. Before you remove the piston, clear the top of the bore from carbon deposits with a dull scraper or soft brush and for any wear ridges, use a ridge reamer to cut them without removing too much metal. If your robot has J-jet cooling nozzles, take them off. Make sure each piston's cylinder number is stamped on top and away from the piston's center as well as from the piston pin and both the connecting rod and the cap should also carry the same markings. With great care, take out the connecting rod bolts and caps and use a hammer handle to gently push the piston and rod out of the cylinder bore after that. Put the piston/rod assemblies into a rack for their storage. Put pistons and pins in a solvent, rinse with hot water, air dry them with compressed air and leave them in the solvent overnight so that carbon deposits start to dissolve. Fill the ring grooves with a broken piston ring, remove the debris and clean again. Wash the connecting rods using the same method. Inspect the pistons for damage and to check if the piston skirt diameter is at least 101.775 mm. Look for damage in the upper groove and check that the clearance in the intermediate ring groove ranges from 0.045 mm to 0.095 mm. Measure the oil groove clearance which must be between 0.040 mm and 0.085 mm and check the pin bore which should be between 40.006 mm and 40.012 mm. Inspect the pist The connecting rod should be free from dents or harm and the pin bore must be between 40.019 mm and 40.042 mm. Before installation, oil the inside of the cylinder and the rings, place the rings on the piston and squeeze them using the compressor tool. Secure the piston and rod into the cylinder bore in the correct position and push the piston down so it sits about 50 mm below the top of the block. Coat the threads leading into the head part of the connecting rod bolts and make sure the long part of a fractured type connecting rod is near the intake side. Set the rod cap and bolts in place, tightening them once to 30 Nm, again to 60 Nm and for the last time while turning them 60° clockwise. The crankshaft should rotate easily and you should also determine the clearance at the connecting rod and crankshaft. If your vehicle has J-jet piston cooling nozzles, install them now, then torque the block stiffener to 43 Nm, the suction tube, oil pan and cylinder head. Afterward, change the filter, fill the crankcase with new engine oil, prefill the filter, connect the battery negative cables again and turn on the engine.