JeepParts

My Garage

My Account

Cart

OEM 2005 Jeep Grand Cherokee Drive Shaft

Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Drive Shafts found

2005 Jeep Grand Cherokee Drive Shaft Part Number: 52853004AF

$914.21 MSRP: $1410.00You Save: $495.79 (36%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Rear 1-Piece

- Replaces: 52853004AE, 52853004AC, 52853004AD

- Item Weight: 23.10 Pounds

- Item Dimensions: 53.0 x 8.4 x 6.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52853004AF

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Jeep Grand Cherokee Drive Shaft Part Number: 52105728AE

$1230.88 MSRP: $1815.00You Save: $584.12 (33%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52105728AD

- Item Weight: 19.30 Pounds

- Item Dimensions: 41.3 x 6.9 x 5.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52105728AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Jeep Grand Cherokee Drive Shaft Part Number: 52105758AE

$1683.07 MSRP: $2270.00You Save: $586.93 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52105758AD

- Item Weight: 20.30 Pounds

- Item Dimensions: 5.6 x 5.8 x 39.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52105758AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Jeep Grand Cherokee Drive Shaft Part Number: 52105760AF

Product Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Rear 1-Piece

- Replaces: 52105760AE, RL105760AF, 52105760AD, 52105760AC

- Item Weight: 18.70 Pounds

- Item Dimensions: 46.2 x 8.2 x 7.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52105760AF

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Jeep Grand Cherokee Drive Shaft Part Number: 52853006AF

Product Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Rear 1-Piece

- Replaces: 52853006AC, 52853006AE, 52853006AD

- Item Weight: 20.30 Pounds

- Item Dimensions: 21.2 x 10.0 x 9.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52853006AF

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Jeep Grand Cherokee Drive Shaft Part Number: 52105726AF

Product Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Rear 1-Piece

- Replaces: 52105726AD, 52105726AE, 52105726AC

- Item Weight: 21.10 Pounds

- Item Dimensions: 54.1 x 11.2 x 9.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52105726AF

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

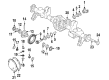

2005 Jeep Grand Cherokee Drive Shaft Parts and Q&A

- Q: How to Measure Drive Shaft Output Angles with an Inclinometer on 2005 Jeep Grand Cherokee?A: To measure the front (output) angle on the ON front propeller shaft, place Inclinometer 7663 on the machined ring of the pinion flange and for the shaft angle, position the inclinometer on the tube of the propeller shaft. You should use the rear section of the transfer case/transmission flange for the output (rear) angle on the propeller shaft. Support the vehicle at its axles so it sits level and let the wheels and propeller shaft do their job. Should there be universal joint snap rings, take them out so the base sits securely and flat. Turn the shaft so the transmission/transfer case output bearing cap faces down and make your measurements looking from front to back and always from the same side of the vehicle. After you place the inclinometer on either the yoke bearing cap or pinion flange ring straightforwardly near the shaft center and align the bubble in the glass, write down the measured angle-this will give you the Output Yoke Angle. Later, turn the propeller shaft 90 degrees and affix the inclinometer to the tube or cap on ON shaft. With its tube parallel to the shaft again, look through the sight glass to center the bubble. This reading can also be obtained at the other end of the shaft. The output operating angle is found by taking away the smaller figure from the larger figure. Afterward, move the propeller shaft so the inclinometer is pointing at it. Hold the device above the pinion yoke bearing cap and, if the bubble is centered in the sight glass, write down the angle. Simply take away the smaller angle from the larger to discover the axle Input Operating Angle. It is important that the operating angle cancellation is no more than 1 degree and 3 degrees for the U-joint system and 10 degrees for the constant velocity joint, plus having at least 1/2 of one degree continuous operating angle on the propeller shaft and no more than 1 1/2 degrees for the U-joint system.