JeepParts

My Garage

My Account

Cart

OEM 2006 Chrysler 300 A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 A/C Clutches found

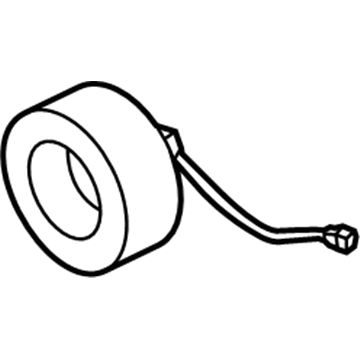

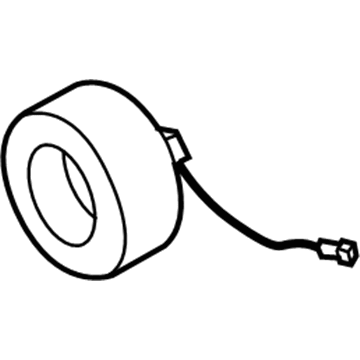

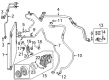

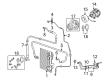

2006 Chrysler 300 Clutch Coil Part Number: 5003681AA

$186.95 MSRP: $279.00You Save: $92.05 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil - A/C Clutch; A/C Compressor Clutch Coil; Clutch; Coil; Coil A/C Clutch; A/C Compressor Clutch

- Replaces: 5072863AA

- Item Weight: 2.10 Pounds

- Item Dimensions: 5.1 x 4.7 x 2.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5003681AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

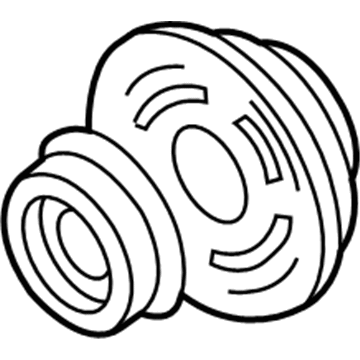

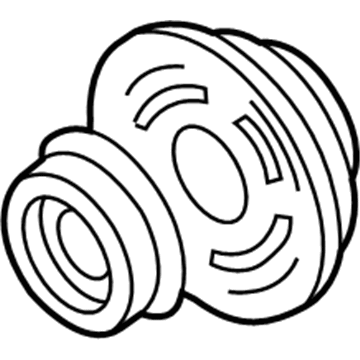

2006 Chrysler 300 Hub Assembly Part Number: 5179340AB

$299.82Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; A/C Compressor Clutch; Clutch Plate & Hub Assembly

- Replaces: 5179340AA

- Item Weight: 3.80 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5179340AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

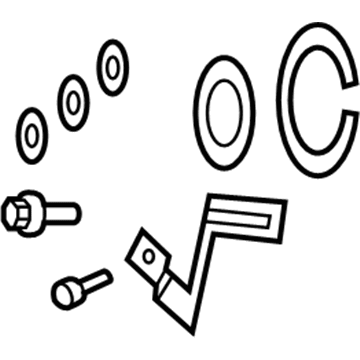

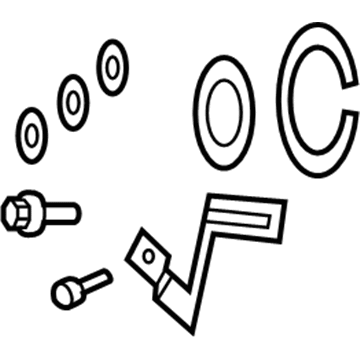

2006 Chrysler 300 Clutch Kit Part Number: 5140428AA

$4.56 MSRP: $36.75You Save: $32.19 (88%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Package - A/C Compressor; A/C Compressor Clutch; Hardware Kit; Clutch Overhaul Kit A/C Compressor with Snap Rings, Washers, Screws, Pulley Bolt.

- Item Weight: 1.20 Pounds

- Item Dimensions: 2.8 x 2.7 x 0.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5140428AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Chrysler 300 Hub Assembly Part Number: 5140426AA

Product Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Clutch Plate & Hub Assembly; Pulley; Pulley Hub Kit A/C Compressor; A/C Compressor Clutch

- Item Weight: 3.80 Pounds

- Item Dimensions: 7.3 x 7.1 x 3.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5140426AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Chrysler 300 Clutch Coil Part Number: 68000489AC

Product Specifications- Other Name: Coil - A/C Clutch

- Replaces: 68000489AB

- Item Weight: 2.20 Pounds

- Item Dimensions: 5.3 x 4.6 x 2.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68000489AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Chrysler 300 Hub Assembly Part Number: 5179519AA

Product Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Clutch Plate & Hub Assembly; Pulley Hub Kit A/C Compressor; A/C Compressor Clutch

- Item Weight: 3.70 Pounds

- Item Dimensions: 5.5 x 5.3 x 1.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5179519AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Chrysler 300 Clutch Part Number: 5140427AA

Product Specifications- Other Name: Clutch Package - A/C Compressor; A/C Compressor Clutch; Clutch Overhaul Kit A/C Compressor

- Item Weight: 1.30 Pounds

- Item Dimensions: 2.8 x 2.6 x 0.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5140427AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Chrysler 300 A/C Clutch Parts and Q&A

- Q: Can the A/C Clutch Be Serviced Without Discharging the Refrigerant System on 2006 Chrysler 300?A: Refrigerant can safely stay at full charge during compressor clutch service. First, cut the connection to the negative battery cable and then remove the accessory drive belt. Take the engine wire harness connector for the A/C compressor clutch coil off the clutch field coil wire harness connector on the A/C compressor's top. Take out the bolts connecting the A/C compressor to the engine and hold it lightly. The shaft bolt on the compressor should be unscrewed while the clutch plate is held in place by a band-type or strap wrench. Don't force anything in the area where the clutch plate comes in contact with the pulley and bearing assembly to avoid damage. Firmly hit the clutch plate with a plastic mallet to slide it off the splines on the compressor shaft, then take out the clutch plate along with any shim(s). Use special tool C-4574 or equivalents to take out the outer snap ring, then remove the pulley and bearing assembly from the front cover of the compressor. Unscrew the bracket and the ground clip attached to the top of the compressor for the clutch coil pigtail wire. Remove the external snap ring from the clutch field coil, hold the clutch field coil from the front cover of the compressor housing and pull it off. When installing, fit the back end of the clutch coil onto the hole in the compressor front cover through the dowel pin. Attach the clutch field coil with a new snap ring, with the part that faces away from you, the bevel and the eyelets in the correct position. Place the external snap ring over the clutch field coil and be sure it is firmly set in the groove. attach and fasten the screw in place for the clutch field coil wire harness connector bracket and ground clip. Make sure you don't scratch the friction surfaces when installing the pulley and bearing system. Fix the assembly on the front cover of the A/C compressor and tap it with a block of wood if that helps. Secure the pulley and bearing in the right place with the provided snap ring. If keeping the old clutch plate and pulley and bearing assembly, put the old shims against the shoulder on the compressor shaft; if using new shims, add a trial stack of shims 2.54 mm thick. Screw the clutch plate onto the compressor shaft and tighten the bolt to a torque of 19 N.m. You should look at the air gap in different areas after tightening and use shims wherever it is too small. After that, install all the bolts securing the A/C compressor to the engine, attach the engine wire harness to the A/C compressor's clutch coil, put on the accessory drive belt and connect the negative battery cable again.