JeepParts

My Garage

My Account

Cart

OEM 2006 Jeep Liberty Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshafts found

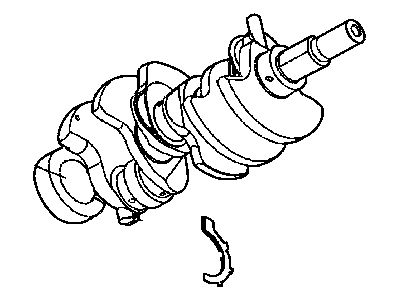

2006 Jeep Liberty Crankshaft Part Number: 53020959AB

$629.85 MSRP: $959.00You Save: $329.15 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft See Note

- Item Weight: 48.20 Pounds

- Item Dimensions: 28.4 x 10.1 x 8.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53020959AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

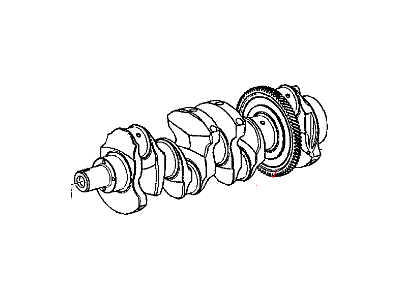

2006 Jeep Liberty Crankshaft Part Number: 68019322AA

Product Specifications- Other Name: Crankshft

- Replaces: 5093881AB

- Item Weight: 50.00 Pounds

- Item Dimensions: 24.0 x 11.9 x 9.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68019322AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Jeep Liberty Crankshaft Parts and Q&A

- Q: How to Safely Extract the Crankshaft from an Engine on 2006 Jeep Liberty?A: Before removing the crankshaft, the engine should be taken out of the vehicle and then the engine oil pump must be removed. It is important not to dig on the oil pan gasket because it is held to the cylinder block in three places and will not be separated when the oil pan is removed. After that, take out the bolts holding the bedplate, note where the stud bolts are, then remove the connecting rods off the crankshaft, making sure not to scratch the important seals between the bedplate and block. Be sure to handle the bedplate carefully, since it holds the lower main bearing halves, as placing them incorrectly can badly harm the crankshaft. Place a bar in the cast openings on the bedplate to loosen it, then take out the crankshaft and its tone wheel. If the connecting rod and main bearing bores show any scoring or blueing on the metal, then you may have to disassemble more of the engine. If the connecting rod bearings prove to be worn, the cylinder heads have to be removed so that the piston and rod can be checked; if those areas are worn, the whole engine must be changed. When necessary, take out the main bearing halves from both the cylinder block and bedplate, tidy the surface of the main bearings, clean the inside of the main bearings and inspect the bedplate to check for any main bearing bore cracks or scoring. Look at the crankshaft thrust washers for any wear and tear and check the oil pan gasket/windage tray for any splits or tears. During installations, coat the fitment part of the upper main bearings with engine oil, fit the crankshaft tone wheel and tighten the mounting screws to 15 Nm (11 ft. lbs.) and finally place the thrust washers around the crankshaft and push it properly into the cylinder block. Mopar Engine RTV sealant should be used on the bedplate to cylinder block mating surface to hold back major oil leaks and guarantee the sealing surfaces are clean. Place 2.5 mm (0.100 inch) of Mopar Engine RTV sealant on the mating surface, cover the crankshaft journals with clean engine oil and lay the bedplate on the cylinder block. Spray the bedplate retaining bolts with clean engine oil, install them all, check the stud bolt locations and tighten them in the correct order. Twist bolts 1D, 1G and 1F until the bedplate touches the block, then tighten bolts 1A - 1J to 54 Nm (40 ft. lbs.) and bolts 1 - 8 to 7 Nm (5 ft. lbs.) for 90°. Finish by fastening bolts A - E to 27 Nm (20 ft. lbs.). Measure the end play of the crankshaft, set the connecting rods in place and check their side clearance, afterward, add the oil pump and oil feed lines.