JeepParts

My Garage

My Account

Cart

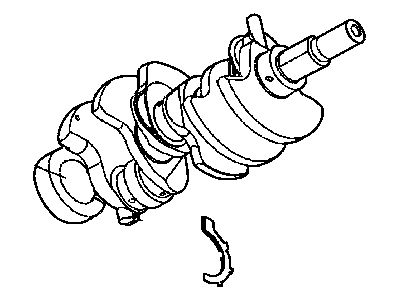

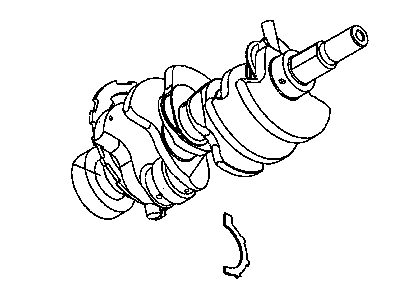

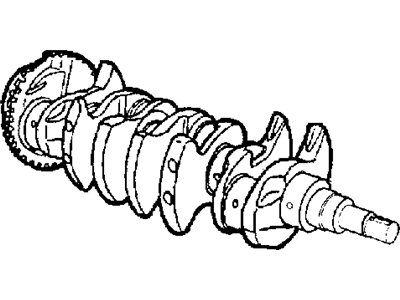

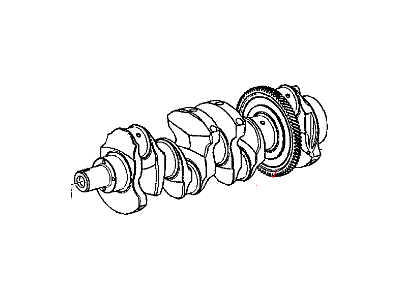

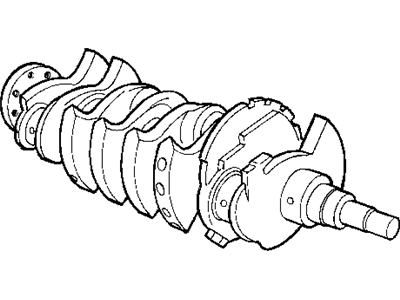

OEM Jeep Liberty Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Crankshafts found

Jeep Liberty Crankshaft Part Number: 53020959AB

$629.85 MSRP: $959.00You Save: $329.15 (35%)Ships in 1-2 Business DaysJeep Liberty Crankshaft Part Number: 53020959

$468.10 MSRP: $593.40You Save: $125.30 (22%)Ships in 1-2 Business DaysJeep Liberty Crankshaft Part Number: 4781643AA

$539.13 MSRP: $818.00You Save: $278.87 (35%)Ships in 1-2 Business DaysJeep Liberty Crankshaft Part Number: 68019322AA

Jeep Liberty Crankshaft Part Number: 4621917

Jeep Liberty Crankshaft

Choose OEM Crankshaft that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Crankshaft follows strict manufacturing steps to lock in quality and fit. If your Jeep Liberty matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Liberty parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Jeep Liberty Crankshaft Parts and Q&A

- Q: How to Remove and Replace a Crankshaft in an Engine Assembly on Jeep Liberty?A:In order to replace and remove the crankshaft one should remove the engine assembly of the car, then to remove the crankshaft rear oil seal and flex plate. It should then be ensured that the engine is put on a repair stand and that the oil must be drained out of the engine along with the Oil Filter. This should be followed by removal of an Oil Pan, Timing Belt covers, timing belt, oil pump, and balance shafts with housing assembly. The caps on the connecting rods should be marked with permanent ink or paint marker avoiding to use a number stamp or punch to ensure that no damage occurs. The connecting rod pinholed and all other perforating bolts and caps are to be removed without harming the fracture rod and cap metal work and the connecting rod bolts are not to be reused. Every bedplate bolt in the engine block should be loosened and also the bedplate should be tapped off of the dowel pins but not pried in one direction otherwise you will have them off center. The crankshaft can be removed then without damaging the main bearings or journals. The mounting screws of the target ring are to be loosened and disregarded after that, the target ring is to be taken off the crankshaft. The crankshaft journals must be examined to note excessive wear, taper and scoring and the journal grinding should not be over 0.305 mm (0.012 inch) under standard journal diameter, and thrust faces of No.3 main bearings marked should not be ground. Oil holes are to be ground, and rough edges should be taken out, and finally all the passages trimmed. During installation the main bearing shells are to be installed with the lubrication groove on the cylinder block and the oil holes in the bearing and the cylinder block check with each other and bearing tabs are to seat in place. One has to be vigilant enough not to get oil on the bedplate mating surface. Prior to applying the crankshaft the bearings and journals must be oiled, only the prescribed anaerobic sealant need be used on the bedplate. The cylinder block should be covered with a Mopar Bed Plate Sealant (in the form of a bead 1.5 to 2.0 mm (0.059 to 0.078 inch) thick). The lower main bearings are to be pushed into the main bearing cap/bedplate (with the bearing tabs to be seated) after which the main bearing/bedplate is to be put into the engine block. The bolts should be oiled at the thread points, and the bolts of the bedplate main bearing to engine block should be mounted on finger tight and tighten fix until the bedplate touches the cylinder block. The best way to guarantee that the thrust bearings line up is by rotating the crankshaft until the number 4 Piston reaches TDC and is slid back toward the Flywheel and front and back until it reaches its extreme positions with a tool slotted between the rear of the cylinder block and the rear crankshaft counterweight forcing the crankshaft to the frontward position. The order to tighten bolts should be followed with 41 Nm (30 ft. lbs.) and tightened again to the same torque but with 1/4 turn. Next the main bearing bedplate to engine block bolts are to be similarly torqued, in turn, to 28 Nm (20 ft. lbs.). Once installed crankshaft turning torque must be measured and it must not be more than 5.6 Nm (50 inch lbs.). The connecting Rod Bearings and connect rod caps must be fitted and connecting rod bolts must be torqued to 27Nm (20ft. lbs.) + 1/4 turn. Install balance shafts and housing assembly, oil pump and pickup tube, timing belt rear cover, timing belt, and timing belt front covers then the engine support bracket and oil pan, oil filter and the crankshaft rear oil seal (the oil pump bolt should be torqued to 95 Nm (70 ft. lbs.) after Mopar Lock & Seal Adhesive has been applied to the brake lines and oil-pan to oil filter studs). Lastly the engine assembly is to be installed.

- Q: How to Properly Install a Crankshaft and Ensure All Procedures Are Followed on Jeep Liberty?A:Pick out the correct main bearings for the installation and do not harm the crankshaft's bearing surfaces during installation. Before continuing, fasten a sealant on the tone wheel retaining screws. The main bearing halves at the top must be cleaned and oiled with good engine oil and then the crankshaft timing wheel is installed and screwed in place using 15 Nm (11 ft. lbs.) torque. Insert the crankshaft into the cylinder block and then put the thrust washers in place. At the start, clean and rub Mopar(R) Engine RTV sealant over the mating surface between the bedplate and cylinder block to avoid serious oil leaks from forming. Put a small strip of Mopar(R) Engine RTV sealant, measuring 2.5mm (0.100 inch), along the gap between the cylinder block and the bedplate. Our manual shows you that the crankshaft main bearing journals need to be cleanly oiled, the bedplate mounted on the cylinder block and the retaining bolts on the bedplate lubricated before being tightened. Thread the bedplate bolts, so stud bolts 1D, 1G and 1F are in the right places, after which tighten bolts 1A - 1J to 54 Nm (40 ft. lbs.), then 1 - 8 to 7 Nm (5 ft. lbs.), add an extra 90° to bolts 1 - 8 and tighten bolts 1A - 1E to 27 Nm (20 ft. lbs.). First, measure the crankshaft end play, then install the connecting rods, make sure there is enough clearance on each side, install the oil pump and finally fit the engine.