JeepParts

My Garage

My Account

Cart

OEM 2009 Dodge Ram 3500 Sway Bar Bushing

Stabilizer Sway Bar Bushing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Sway Bar Bushings found

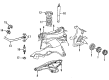

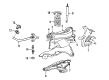

2009 Dodge Ram 3500 Stabilizer Bar Bushing, Front Part Number: 52013793AA

$30.83 MSRP: $45.95You Save: $15.12 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bushing - Stabilizer Bar; Front Suspension Stabilizer Bar Bushing Kit; Sway Bar Bushing Kit.; Bushings; Bushing Stabilizer Bar

- Position: Front

- Item Weight: 0.60 Pounds

- Item Dimensions: 2.4 x 2.3 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52013793AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

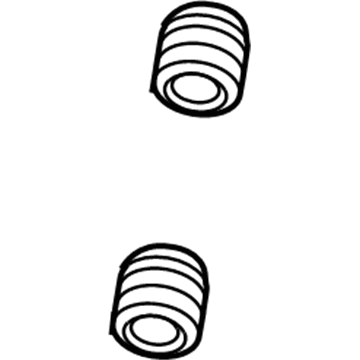

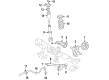

2009 Dodge Ram 3500 Stabilizer Bar Bushing, Front Part Number: 52013697AA

$25.93 MSRP: $38.40You Save: $12.47 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bushing - Stabilizer Bar; Front Suspension Stabilizer Bar Bushing Kit; Sway Bar Bushing Kit.; Stabilizer Bar Clamp; Bushings; Bushing Stabilizer Bar

- Position: Front

- Item Weight: 0.60 Pounds

- Item Dimensions: 2.8 x 2.6 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52013697AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

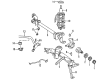

2009 Dodge Ram 3500 Link Bushing, Front Part Number: 52037916

$17.48 MSRP: $26.05You Save: $8.57 (33%)Product Specifications- Other Name: Grommet - Stabilizer Bar; Suspension Stabilizer Bar Link Bushing, Front; Sway Bar Bushing; Stabilizer Link Grommet; Grommet Stabilizer Bar; Grommet, Front Link; Grommet, Link; Grommet Link

- Position: Front

- Item Weight: 0.60 Pounds

- Item Dimensions: 1.2 x 1.5 x 1.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52037916

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Bushing - Sway Bar; Front Suspension Stabilizer Bar Bushing Kit.; Stabilizer Bar Cushion; Bushings; Bushing Stabilizer Bar

- Position: Front

- Item Weight: 0.50 Pounds

- Item Dimensions: 2.2 x 2.3 x 2.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 52013406AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2009 Dodge Ram 3500 Sway Bar Bushing Parts and Q&A

- Q: How to Service and Repair a Rear Suspension Sway Bar Bushing on 2009 Dodge Ram 3500?A: It is necessary to first remove the spring from the car before you service and repair the sway bar bushing in the rear suspension. After that, do just enough relief cuts on the flared end of the bushing, keeping the spring safe, so that you can use a punch to slide the bushing metal down and out. After that, press the spring eye into a press and use the best driver for your bushing to push it out.