JeepParts

My Garage

My Account

Cart

OEM Chrysler Cirrus Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Pistons found

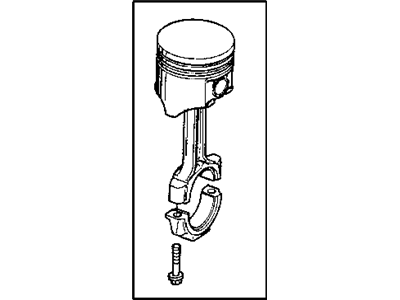

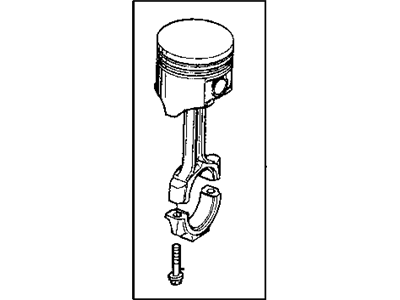

Chrysler Cirrus Piston Part Number: MD309399

$8.15 MSRP: $10.34You Save: $2.19 (22%)Ships in 1-2 Business DaysChrysler Cirrus Piston Part Number: 68067617AA

Chrysler Cirrus Piston Part Number: 5103509AA

Chrysler Cirrus Piston Part Number: MD309393

Chrysler Cirrus Piston Part Number: 4796212

Chrysler Cirrus Piston

Choose OEM Piston that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Piston follows strict manufacturing steps to lock in quality and fit. If your Chrysler Cirrus matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Cirrus parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Chrysler Cirrus Piston Parts and Q&A

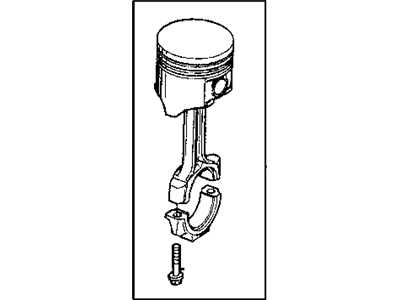

- Q: How to Safely Remove and Replace Engine Pistons on Chrysler Cirrus?A:The cylinder head should be removed before you can take out and replace the pistons. Mark and insert the piston for the corresponding cylinder with the highest point top while you eliminate the top of the cylinder using a reliable ridge reamer. After that, take out the oil pan and mark each cylinder's number on the side of the rod and cap. It's important to remember that the pistons have a stamping that points toward the engine's front. By rotating the Crankshaft to center the rods, take out the pistons and connecting rods from the top of the block, remove the Balance Shaft Assembly and the connecting rod cap bolts and pull the pistons and rods out of the bore without damaging the crankshaft journal. When the bearing is removed, put on the bearing cap at the top of the rod, because pistons and rods are serviced as a single group. When installing, the oil ring and compression ring gaps must be uneven, not running parallel to the oil ring rail gap. Make certain that the ends of the oil ring expander touch and that the gaps in the rails are correct before putting the ring compressor in place. Once the piston and rings are in clean engine oil, slide the ring compressor over the piston so that the rings keep their original places. The front of the engine should be aligned with the directional stamp on the piston. Spin the crankshaft until the connecting rod journal sits squarely in the cylinder bore, insert the whole rod and piston assembly and carefully guide the rod over the crankshaft journal. Piston the rod down by tapping it with a hammer handle and at the same time, put the rod on the centerline of the connecting rod journal. Never reuse connecting rod cap bolts; instead, oil the clean threads on the new bolts, install them finger tight, torque them each alternately and skip using a torque wrench for the second part of the procedure. Then, screw the bolts on to 27 Nm plus a 1/4 turn and check the clearance on the connecting rod side by inserting a feeler gauge.