JeepParts

My Garage

My Account

Cart

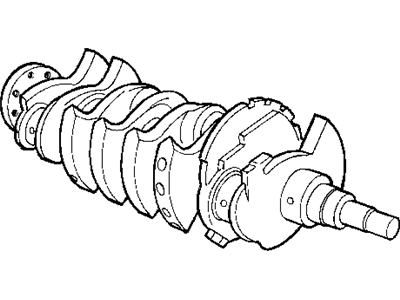

OEM Chrysler Cirrus Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

Chrysler Cirrus Crankshaft Part Number: 4621917

Chrysler Cirrus Crankshaft

Choose OEM Crankshaft that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Crankshaft follows strict manufacturing steps to lock in quality and fit. If your Chrysler Cirrus matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Cirrus parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Chrysler Cirrus Crankshaft Parts and Q&A

- Q: How to Remove and Install a Crankshaft in an Engine Assembly on Chrysler Cirrus?A:Before you remove the crankshaft, take away the engine assembly from the vehicle and separate it from the transaxle. After that, the flex plate and crankshaft rear oil seal come off, allowing the engine to be mounted on a repair stand. The Oil Filter and oil pan should come off as well as the Timing Belt cover, timing belt and the oil pump. You should remove the balance shaft assembly and all the cap bedplate bolts from the engine's main bearings. Rap the bedplate loose from the dowel pins beneath the cylinder block using a mallet carefully, without trying to push up just one part to keep the cylinder block, bedplate and thrust bearing parts aligned. If the bedplate is removed all around evenly, the crankshaft can be effortlessly lifted from the cylinder block without hurting the main bearings or the journal. Before installing, match the groove on the main bearing shells with the groove in the block to set the oil holes in the bearings and bearing tabs across the block, making sure everything is seated correctly. You should avoid oil on the bedplate mating surface because this helps the sealer do its job effectively. Before putting the crankshaft in, apply oil to the bearings and journals and only dab a small amount of the proper anaerobic sealer onto the bedplate to shield the engine. The Mopar Bed Plate Sealant should be placed as a bead with a length of 1.5 to 2.0 mm on the cylinder block. Allowable fitment of the lower main bearing and its correct placement, with the bearing tabs matching, ahead of fitting the main bearing/bedplate into the engine block and the positioning of the upper bedplate in the main bearing cap. Grease the threads of the bolts with clean engine oil and torque down bolts 11, 17 and 20 only by hand until there is an even touch between the bedplate and the cylinder block; then tighten them securely. For proper alignment, turn the crankshaft until the number 4 Piston is at top dead center, then move the crankshaft forwards and backward to its limits. Fitting a wedge tool behind the block and in front of the counterweight will help secure the crankshaft in its furthest forward position. Place and tighten the bolts one by one to 41 Nm (30 ft. lbs.), then take out the wedge bar. The bolts should be tightened for a second time to 41 Nm (30 ft. lbs.), then rotated a 1/4 turn more in the same order. The bearing bedplate to engine block bolts (11 through 20) need to be tightened to 28 Nm (20 ft. lbs.) in order of assembly. The crankshaft turning torque should be checked after adding the main bearing bedplate and ought to be less than 5.6 Nm (50 in. lbs.). The balance shaft assembly, oil pump, timing belt and covers should come next and then the oil pan and oil filter. Bolt the crankshaft rear oil seal and flex plate and be sure to use Mopar Lock & Seal Adhesive on the bolts and tighten them to 95 Nm (70 ft. lbs.). The transaxle should be fitted to the engine and the connection bolts tightened to 101 Nm (75 ft. lbs.), after which the engine assembly should be installed.