JeepParts

My Garage

My Account

Cart

OEM Chrysler Concorde Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Piston Ring Sets found

Chrysler Concorde Piston Rings Part Number: 5241052

$17.57 MSRP: $22.27You Save: $4.70 (22%)Ships in 1-2 Business DaysChrysler Concorde Piston Rings Part Number: 68001386AA

$280.98 MSRP: $419.00You Save: $138.02 (33%)Ships in 1-2 Business DaysChrysler Concorde Piston Ring Set Part Number: 4897032AA

$27.88 MSRP: $35.34You Save: $7.46 (22%)Ships in 1-2 Business Days

Chrysler Concorde Piston Rings Part Number: 4897035AB

Chrysler Concorde Piston Ring Set Part Number: 4897027AB

Chrysler Concorde Piston Ring Set Part Number: 4626660

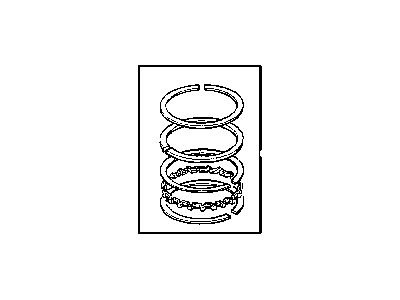

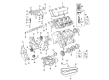

Chrysler Concorde Piston Ring Set

Choose OEM Piston Ring Set that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Piston Ring Set follows strict manufacturing steps to lock in quality and fit. If your Chrysler Concorde matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Concorde parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Chrysler Concorde Piston Ring Set Parts and Q&A

- Q: How to Service and Repair a Piston Ring Set on Chrysler Concorde?A:Remove the Piston and connecting rod first, then carefully remove the No. 1 and No. 2 piston rings and the rail and expander of both oil rings. The installation should start by measuring how close the No. 2 piston ring is to the cylinder bore and the piston. The dot on the ring should be aligned upwards so it is facing the top of the piston. Guide the oil ring expander into place first, then the upper oil ring side rail, the lower oil ring side rail, then No. 2 intermediate piston ring and finally No. 1 upper piston ring. For the side rail installation, secure one end between the piston ring groove and the expander, hold tight and press it into place by hand, without needing a piston ring expander. Before everything else, fix the upper side rail on the cylinder and then proceed with the lower side rail. Then add the No. 2 piston ring and lastly install the No. 1 piston ring. Make sure the piston ring end gaps are set correctly and that the oil ring expander gap is at least 45° away from the side rail gaps and do not place the rings on the piston pin center or in thrust direction because having gaps lets oil pass easily through the ring.

- Q: How to Properly Install a Piston Ring Set on Chrysler Concorde?A:Before inserting the ring, clean the cylinder bore; then, put in the ring and press it down with the Piston for a square fit. Try to measure the ring gap with a feeler gauge at least 12 mm (0.50 in.) from the bottom of the cylinder bore, as the ring is placed. The following step is to inspect the width between the outer ring and the groove in the cylinder block. To take out the piston and rod, remove the connecting rod and piston, then apply a ring expander tool to eject No. 1 and No. 2 piston rings, the upper oil ring side rail, lower oil side rail and both ends of the oil ring expander. Before installation, double-check how much space remains between the cylinder bore, piston and piston rings. The manufacturers determine the placement of the No. 2 ring by its I.D. dot (dot on the top). Place the piston rings in the engine from the following top to bottom: oil ring expander, upper oil ring side rail, lower oil ring side rail, No. 2 intermediate piston ring and No. 1 upper piston ring. For the side rail installation, place one end between the piston ring groove and the expander, grip firmly and push down enough to place the side rail in position without the piston ring expander. Begin by setting up the upper rail; after, fit the lower rail next and then add the No. 2 and No. 1 piston rings. Make sure the piston ring end gaps are in place and that the oil ring expander gap is at least 45° over from the side rail gaps, not on the piston pin center or in the thrust direction, as fins should be staggered to control oil properly.