JeepParts

My Garage

My Account

Cart

OEM Chrysler Prowler A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 A/C Clutches found

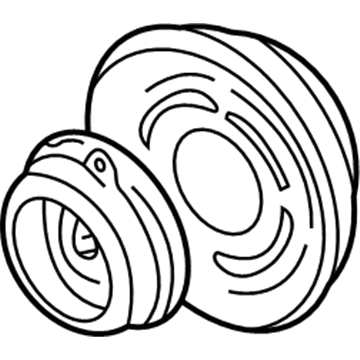

Chrysler Prowler Compressor Clutch Part Number: 4723014

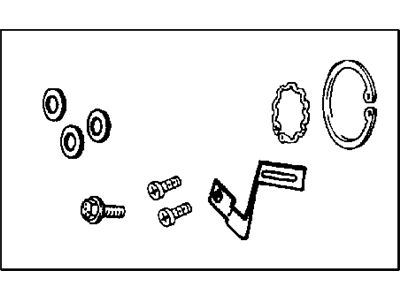

$122.41 MSRP: $155.18You Save: $32.77 (22%)Ships in 1-2 Business DaysChrysler Prowler Hardware Kit Part Number: 4723011AB

Chrysler Prowler A/C Clutch

Choose OEM A/C Clutch that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each A/C Clutch follows strict manufacturing steps to lock in quality and fit. If your Chrysler Prowler matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Prowler parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

A/C Clutch is one of those vital parts used in Chrysler Prowler vehicles that are globally famous because of their mechanical effectiveness and durability. Here is this A/C Clutch, which effectively helps to transmit engine power towards the A/C compressor for comfortable temperature in the car. The electronic mechanism involves attracting a drum situated within the belt pulley whereby engagement and disengagement can be easily done with no exerted force which is excellent for the engine resulting in efficiency. Chrysler Prowler A/c Clutch fits most of the Prowler models, and therefore, useful to the Prowler users whether professional or occasional users. It enhances the cooling features as well as the fuel efficiency of the car; that is why it is central to the vehicle's structural health. Also, the A/C Clutch has been designed to last long hence meeting the Chryslers engineering principles of durability and reliability. The complimentary movements like installation, whether the A/C Clutch is engaged or disengaged, further makes it unique in the automotive market; besides it minimizes the risk of overheating and mechanical failure hence increasing the safety of automobiles. All in all, A/C Clutch demonstrates the company's dedication to creating high-quality products that will allow drivers to achieve the desired level of comfort in their Chrysler Prowler.

Chrysler Prowler A/C Clutch Parts and Q&A

- Q: How to Service and Repair an A/C Clutch on Chrysler Prowler?A:Take the compressor out of the vehicle and, using a specially designed oil filter removal tool, remove the bolt nearby the compressor clutch. Use a plastic hammer to hit the clutch plate which should be taken off along with any shims, while steering clear of using screwdrivers between the clutch plate assembly and pulley. Then, take out the pulley retaining snap ring with Snap Ring Pliers (C-4574) and bring the pulley assembly away from the compressor. First remove the screw holding in the coil wire bracket/ground clip and then the wire harness, next take out the snap ring to release the field coil from the compressor housing. Check the clutch pulley and front plate for wear and damage; replace them if there is too much sign of wear or scoring. Should you discover oil around the friction surfaces, carefully look at the nose area of the shaft. If the felt in the front cover is wet, replace the seal. In addition, make sure the bearing is even and not greasy in places and get a new one if needed. Always check if there are signs of deep line or wear on both the rotor-pulley and armature plate and make sure there is no grease around these areas. As you fit the pin in the back of the field coil with its matching hole in the compressor end housing, position all the wires out of the way and put the screw through the diode and coil wire bracket to secure it. Use C-4574 Snap Ring Pliers to fit the retaining snap ring with the bevel side facing outward and the eyelets correctly in place. Place the pulley assembly around the compressor shaft, striking gently if it sticks and use the retaining snap ring to hold it in place (again, with the bevel side facing away from the block). If using the original front plate and pulley assembly, try fitting the old shim; else, place two new shims, 2.54 mm (0.10 in.) each, on the shaft against the shoulder. For new front plates and pulley assemblies, position a dial indicator so that there is a gap of 0.35 to 0.65 mm (0.014 to 0.026 in.) between them and add or remove shims as needed to maintain this gap. Once the barrel bolt is in, tighten the compressor shaft bolt to 17.5 ± 2 Nm (155 ± 20 in. lbs.) and make sure the air gap is correct in different spots after installing the bolt. Cycle the A/C clutch twenty times (10 seconds ON, 10 seconds OFF) with the car in A/C mode, the engine RPM between 1500 and 2000 and the blower set to high speed to bring in the friction surfaces and improve the clutch's strength.