JeepParts

My Garage

My Account

Cart

OEM Chrysler Prowler Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Rod Bearing found

Chrysler Prowler Connecting Rod Bearing Part Number: 4626657AD

$16.53 MSRP: $24.35You Save: $7.82 (33%)Ships in 1-2 Business Days

Chrysler Prowler Rod Bearing

Choose OEM Rod Bearing that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Rod Bearing follows strict manufacturing steps to lock in quality and fit. If your Chrysler Prowler matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Prowler parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

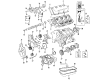

Chrysler Prowler Rod Bearing is an exemplary part utilized in Chrysler Prowler models to enhance the performance as well as keep the vehicle running as expected. Intended for the crankshaft and connecting rods use, the Rod Bearing has low friction for the optimal work of an engine. The quality aspect of Chrysler is therefore seen in the making of these bearings as they may be bi-metal or tri-metal in order to improve their strength and fatigue level. The clearance with which the Rod Bearing controls the oil, usually, ranges from 0.001 to 0.0035 and is very essential in the performance of high-feature engines or high-output engines. This attention to detail not only increases the efficiency of the Chrysler Prowler for some purposes, but also provides an increase in safety by guaranteeing that the engine will run at no more than those parameters as is design. Optional compatibility with different models of Prowler also draws the compatibility of the Rod Bearing and increases preference point among enthusiasts. Thanks to propriety dry Film coatings as well as enhanced lubrication capabilities, Chrysler Prowler Rod Bearing stands out from the automotive market: it can handle performance driving and protect the engine from wear at the same time. Being one of the Chrysler Prowler automobile models, the Chrysler Prowler Rod Bearing is a great example of the company's commitment to providing only the optimal for car enthusiasts; therefore, this car part is among the most important in the Prowler family.

Chrysler Prowler Rod Bearing Parts and Q&A

- Q: What Precautions Should Be Taken When Fitting Rod Bearings on One Bank on Chrysler Prowler?A:Put all the rods on one side and mark the caps as you remove them, since once you take them off you can't put them back in the wrong place. Take a bearing shell and fit the tangs into the machined grooves of the rods and caps, then put on the cap so that the tangs on both parts match. Don't allow more than 0.015 mm (0.0006 in.) of taper or out-of-round on the journal bores; use bearings with 0.025 mm (0.001 in.) and 0.254 mm (0.010 in.) undersized bore. Never install a new half bearing with an old half and never file the bearing caps or the rods. Wrap Plastigage around the connecting rod as you rotate the crankshaft with the rod at the lowest point and without its cap, then wipe off the journal with clean rag. Apply a length of Plastigage the length of the bearing shell inside the bearing cap, placing it 1/4 inch from the center away from the oil hole and reassemble the connecting rod cap without crankshaft rotation. Limply tighten the nuts on the connecting rod cap to 54 Nm (40 ft. lbs.) excluding the last 1/4 turn until the end of the build. Next, remove the bearing cap and compare the plastic ring you used with the markings on the plastigage for its width to determine oil clearance. Because necking can occur in connecting rod bolts, check for it before reusing and discard the bolts if necked. Check the threads by touching them with a scale; if you don't touch all of the threads, replace the bolt. Apply engine oil to the threads before installing the nuts by hand; afterwards, evenly tighten all the nuts in an ordering sequence. For connecting rod side clearance, place a dial indicator on a fixed point of the engine and align the probe with and touching, the connecting rod cap. Adjust the connecting rod to the back of its stroke, set the indication to zero and move it to the front and read the dial. Do the same for all connecting rods as you turn the crankshaft around for access.