JeepParts

My Garage

My Account

Cart

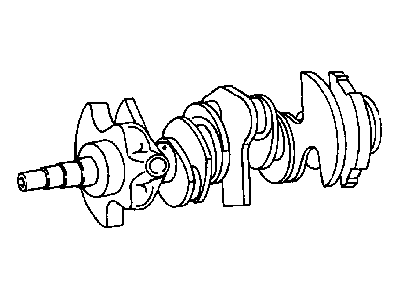

OEM Chrysler Prowler Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

Chrysler Prowler Crankshaft Part Number: 4792692AB

Chrysler Prowler Crankshaft

Choose OEM Crankshaft that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Crankshaft follows strict manufacturing steps to lock in quality and fit. If your Chrysler Prowler matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Prowler parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The crankshaft of Chrysler Prowler cars functions as an essential element because it delivers both dependable performance along with safety capabilities through its operation. Through its operation the Chrysler Prowler crankshaft transforms piston moving back and forth motion into wheel-turning rotations which creates better driving performance. The crankshaft utilizes forged steel as its main material for high-powered applications to resist performance driving demands while remaining durable throughout its operational life with proper servicing. Each Chrysler Prowler vehicle under the multiple models can utilize the Prowler crankshaft for its sturdy design benefits. A crucial step is to watch for crankshaft wear indications through unusual vibrations that show potential mechanical problems. The precise craftsmanship behind the Chrysler Prowler crankshaft differentiates it from others in the market since this structure supports the 7.2-second 0-60 mph capability of the vehicle. The car's design foundation which includes exposed rims and aluminum structure enhances its performance capabilities due to its unique features making them pivotal components of the car. The Chrysler model crankshaft improves vehicle performance while maintaining reliability and safety elements which make it a respected candidate within the automotive market.

Chrysler Prowler Crankshaft Parts and Q&A

- Q: How to Remove and Replace a Crankshaft on Chrysler Prowler?A:The crankshaft should be removed after you take out the engine, Oil Pan and oil pickup tube. After that, get rid of the crankshaft damper, accessory belt idler pulley, front lower, front main and front left side cover plates for the Timing Belt. After removing the old belt and its tensioner, pull off the crankshaft sprocket. Callahan used his finger to pull out the dowel pin from the crankshaft, removed the oil pump assembly and also took out the rear crankshaft oil seal retainer. After removing the rod bearing cap, take out the main bearing cap, since they should both be marked the same. Remove the crankshaft as your last step. Before putting in the crankshaft, check that the journals have no excessive wear, taper or scoring and that limits of vertical ambit or roundness do not pass 0.015 mm (0.0006 in.) and that any removing of material from the journal's surface does not exceed 0.305 mm (0.012 in.) below the established journal diameter. Never use force that might damage the thrust surfaces of the Number 2 main bearing or nick the crank pin or bearing fillet. Once you have ground, brush and hand clean all top and side surfaces so the harshness on the oil holes is removed and the direction of the final shaping of the crankshaft is the same as normal engine rotation. First, add the upper main bearings to the cylinder block and add clean engine oil, before installing the crankshaft. Lubricate the crankshaft, move it as far forward as it will go, install the front thrust washer and then move it back as far as possible to install the rear thrust washer. Drop the lower main bearings into each main bearing cap, lubricate them and then place a bit of lubricant on the main bearing cap bolts before installation. The order to tighten the main cap bolts is inner main cap bolts first, windage tray bolts next and finally tie bolts for the main cap. Tighten the cap bolts of the main bearing cap to 20 Nm by rolling them on by 1/4 turn, check crankshaft end play and install the connecting rods to measure side clearance. Attach the windage tray, smear a bead of grease on each of the bolts and tighten them to 27 Nm and turn 1/4 extra. Secure the main cap tie bolts to 28 Nm (250 in. lbs.), then put the rear crankshaft oil seal retainer and oil seal in place and lastly fit the oil pump assembly. After that, fit the dowel pin back into the crankshaft, timing belt cover, crankshaft sprocket and timing belt; then add the three timing belt covers, crankshaft damper and idler pulley for the accessory belt. The next step is to install the oil pickup tube, tightening the bolt to 28 Nm (250 in. lbs.), fit the oil pan, assemble the engine and run oil into the engine until the correct amount is measured.