JeepParts

My Garage

My Account

Cart

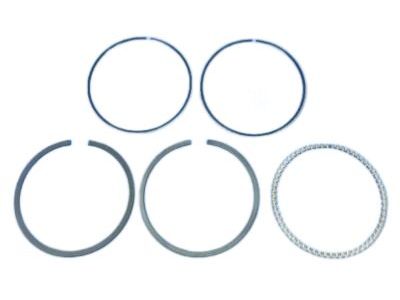

OEM Dodge Dakota Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Piston Ring Sets found

Dodge Dakota Piston Rings Part Number: 68031606AA

$44.45 MSRP: $66.45You Save: $22.00 (34%)Ships in 1-2 Business DaysDodge Dakota Piston Rings Part Number: 4720727

$47.56 MSRP: $60.30You Save: $12.74 (22%)Ships in 1-2 Business Days

Dodge Dakota Piston Rings Part Number: 5012364AE

Dodge Dakota Piston Rings Part Number: 4798324

Dodge Dakota Piston Rings Part Number: 4740259

Dodge Dakota Piston Rings Part Number: 4626636

Dodge Dakota Piston Rings Part Number: 4720653

Dodge Dakota Piston Ring Set

Choose OEM Piston Ring Set that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Piston Ring Set follows strict manufacturing steps to lock in quality and fit. If your Dodge Dakota matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Dakota parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Dodge Dakota Piston Ring Set stands as a leading performance component responsible for Dodge Dakota vehicle operational efficiency. This Piston Ring Set efficiently seals the combustion chamber to achieve maximum fuel-air mixture burning results and regulates gas escape with controlled engine oil usage. The Piston Ring Set from Dodge Dakota fits different model versions of the Dakota which boosts engine performance and protection thus serving as a crucial component for engine longevity. The innovative Dodge Dakota Piston Ring Set comprises thinner components which enhance sealing functions and reduce friction due to the technological advancements of Dodge car throughout the years. Among automotive Piston Ring Sets on the market this solution provides wear reduction alongside improved performance through its arrangement of 1mm top and second rings and 2mm oil control rings. Through its advanced features the car established pickup innovation as an industry leader and the car Piston Ring Set pursues this tradition through optimal engine performance. Investing in the car Piston Ring Set delivers better performance results and improved safety and dependable driving operations which makes it an essential part of the automaker model vehicle components.

Dodge Dakota Piston Ring Set Parts and Q&A

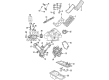

- Q: How to Check and Install a Piston Ring Set on Dodge Dakota?A:Please check the extra space around the rings by wiping the inside of the cylinder and pushing in the old or new ring, keeping the ring 12 mm (0.50 in.) from the end of the bore. Lower the ring into the cylinder using a Piston and with a feeler gauge, check every ring against the correct gap. First, clean the ring grooves from dirt and burrs, fitting the feeler gauge tightly between the ring and the ring land and just replace any ring that fails to meet the requirements. Move the ring around the piston while it's part of the assembly and watch to be sure it does not hit the sides of the groove and notice the No. 1 and No. 2 piston rings are not the same. The order to install piston rings is this: oil ring expander, upper oil ring side rail (1), lower oil ring side rail, No. 2 intermediate piston ring and No. 1 upper piston ring. Fit the oil ring expander under the piston, then slide one end of the upper side rail so it fits snugly under both the expander and piston rings. Press it gently down until it is aligned with the side of the cylinder block and do the same with the other side rail. Install the No. 2 intermediate piston ring onto the piston and insert the No. 1 upper piston ring onto the piston with the help of the piston ring installer. Position the piston ring gaps so that the expander ring gap will always be at least 45° farther than the side rail gaps, never lying over the piston pin center or in the direction it will thrust.

- Q: How to Service and Repair a Piston Ring Set on Dodge Dakota?A:Start by cleaning all the carbon from the ring grooves, checking that oil drain openings and oil ring pin bosses aren't blocked, so that essential metal is not removed from the ring or ring-land area. Make certain the Piston ring grooves have no nicks or burrs on the edges. Place a feeler gauge onto the ring land and ring, tight enough so the ring can move inside the groove freely. Put your ring in the bore and press down on it with the inverted piston, making sure the ring does not touch the cylinder surface below the lower edge of its travel and checking the gap with a feeler gauge between the two ring ends. The oil control rings are symmetrical and can be fitted either direction, put the oil rail spacer in first, then add the side rails. They are separate, so swap them out only when your doctor advises; you can put the top compression ring on, dot side up or side down, but the second you'll know is right if its relatively flat, bottom inside has been chamfered and it's got a spot for correct placement. Drag the ring installer with the second compression ring's dot pointing up and then put the top ring in place. The oil spacer gap should be centered on the piston skirt, the oil rails should be 180° opposite each other on the centerline of the piston pin bore, the No. 2 compression ring gap should follow the top oil rail by 180° and the No. 1 compression ring gap should be 180° further than the No. 2 ring gap.