JeepParts

My Garage

My Account

Cart

OEM Dodge Intrepid Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Exhaust Valves found

Dodge Intrepid Valves Part Number: 4663902

$29.53 MSRP: $43.15You Save: $13.62 (32%)Ships in 1-2 Business DaysDodge Intrepid Exhaust Valve Part Number: 4892094AA

Dodge Intrepid Exhaust Valve

Choose OEM Exhaust Valve that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Exhaust Valve follows strict manufacturing steps to lock in quality and fit. If your Dodge Intrepid matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Intrepid parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

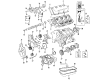

The Dodge Intrepid Exhaust Valve delivers essential functionality to the internal combustion engine of the Dodge Intrepid by enabling proper burnt-gas exhaust during engine exhaust cycles. This precisely designed Exhaust Valve stands vital for sustaining peak engine performance which directly activates fuel efficiency and driving experience quality. Proper function of the Exhaust Valve ensures the Dodge Intrepid operates safely by preventing three major performance problems including engine breakdowns during start-up and reduced engine power capabilities. The Exhaust Valve integrates seamlessly with Dodge Intrepid vehicles that rolled off production lines between 1993 to 2004 to boost their operational efficiency along with their safety which positions it as one vital component of the entire engine operation. The Exhaust Valve in the Dodge Intrepid provides reliability benefits that enable this vehicle to achieve agile handling combined with smooth operation even though its engine comes in various power configurations from 200 hp to 250 hp. A distinctive aspect of the Dodge Intrepid Exhaust Valve consists of its durable fabrication which enables operation under extreme conditions to provide long-term reliability and dependable operation. The reliable nature of the Exhaust Valve solidified brand car's standing within the automotive market so users choose it as their preferred full-sized sedan. The car Exhaust Valve serves as an essential component which boosts the automaker model performance and efficiency and safety thus reinforcing its reputation as an versatile reliable car model.

Dodge Intrepid Exhaust Valve Parts and Q&A

- Q: What Are the Key Differences in Servicing Exhaust Valves and Intake Valves on Dodge Intrepid?A:Before working on the valve, remove the cylinder head and use Special Tool C-3422-B, Valve Spring Compressor, to compress the springs. Remove both locking mechanisms for the valve, as well as the valve springs and spring seat/stem seals and their retainer. Remove any rough edges from the valve stem locking rods, identify each valve and put them back where they originally were to avoid problems. Before installing the valves, cover the stems with clean engine oil and set them into the head. When valves are reground, compare the tip of the valve with the specs; intake should be 47.59 mm (1.8737 inch) and exhaust should be no more than 49.14 mm (1.9347 inch). Adjust the valve tip by grinding it as much as needed so it meets the above requirements, measuring from the head of the cylinder to the top of the valve stem. Then, place the rubber seal/spring seat assembly down onto all the valve guides, keeping the middle rubber seal centered and the garter spring undamaged up top. Place the valve springs and valve retainers onto the engine. Compress the valve springs, set the locks in place and after that release the compressor. Should any of the valves be reground, consistently check the installed height by measuring from the spring seat's top to the spring retainer's base. If the height is out of specification (more than 38.75 mm), fit a 0.762 mm spacer in the head counterbore under the spring seat to reach the right size.

- Q: How to Service and Repair Exhaust Valve and Intake Valves on Dodge Intrepid?A:The cylinder head(s) should be removed before the valve spring of the valve is taken out. Ensure that whatever tools you use to remove the valves don't leave any burrs inside the valve stem lock grooves and thus harm the valve guides. As you take out each valve, check its type so you put it back where it belongs. For assembly, cover the valve stems with clean oil and insert them straight into the cylinder head. Should the valves or seats have been reground, double-check their tip heights. The intake valve may be no bigger than 47.59 mm (1.8737 inch) and the exhaust no bigger than 49.14 mm (1.9347 inch). Should the valve tip height be beyond the specifications, use a grinder to make the tip smaller and follow these measurements, using the surface of the head and upper most part of the stem as the reference. After that, attach the valve spring.