JeepParts

My Garage

My Account

Cart

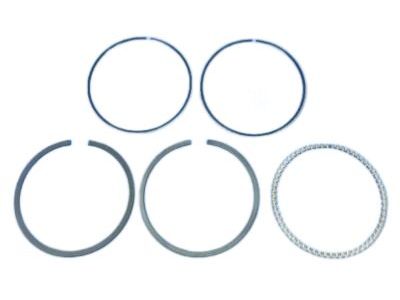

OEM Dodge Nitro Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Piston Ring Sets found

Dodge Nitro Piston Rings Part Number: 5012364AE

Dodge Nitro Piston Rings Part Number: 4897035AB

Dodge Nitro Piston Ring Set

Choose OEM Piston Ring Set that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Piston Ring Set follows strict manufacturing steps to lock in quality and fit. If your Dodge Nitro matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Nitro parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Dodge Nitro Piston Ring Set stands out because of its dependable design which enables secure engine operation in Dodge Nitro vehicles. The car Piston Ring Set shutters the combustion chamber while it facilitates proper fuel-air mixture combustion by blocking gas leaks and acts as a mechanism to control the engine oil. Engine longevity and efficiency depend strongly on the cast iron or steel Dodge Nitro Piston Ring Set that features durable materials for minimizing friction and improving sealing functions. The piston ring set demonstrates flexibility by working with Dodge Nitro models made between 2007 and 2012 thus showing its value in boosting vehicle performance. The current configurations of Dodge Nitro Piston Ring Sets utilize enhanced design parameters that include thinner ring components which enhance both sealing and oil control mechanisms with measurements consisting of 1mm top and second rings alongside 2mm oil control rings. Through these innovations Dodge Nitro obtains improved operational efficiency and safety features which give drivers an enhanced smooth powerful driving experience. Modern driving conditions have favored the car Piston Ring Set because it shows resilience while maintaining its position as a top choice in the automotive sector. A top-notch the automaker car Piston Ring Set purchase enables vehicle operators to develop their model's functionality while maintaining a dependable operational experience throughout multiple years.

Dodge Nitro Piston Ring Set Parts and Q&A

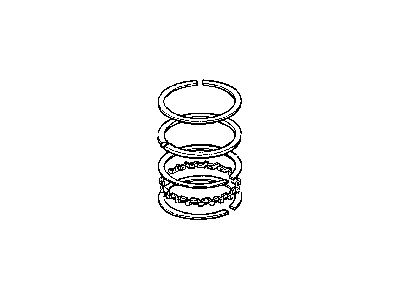

- Q: How to Check and Install a Piston Ring Set on Dodge Nitro?A:Before reinstalling used rings or installing new rings, first clean the cylinder bore, position the ring deep inside the bore and measure the ring gap when at least 12mm (0.50 inch) from the bottom. Take a Piston and insert it to square the ring in the bore, after which push it down and measure the end gap with a feeler gauge, exchanging any rings that are out of range. Check the ring grooves for dirt and scratches, (have them clean if necessary), put a snug feeler gauge between the ring and its land and only keep the rings that fit the specifications. Test if the ring moves freely with no binding by rotating it around the piston and be sure the No. 2 piston ring is correctly placed so the "Dot" mark is visible when seen from the top. To do so, place the oil ring expander, upper oil ring side rail, lower oil ring side rail, No. 2 intermediate piston ring and No. 1 upper piston ring, in sequence. First, set the oil ring expander, then place the upper side rail on one end between the piston ring and the expander ring, press it down and secure the lower side rail the same way. Fit the No. 2 intermediate piston ring using a piston ring installer and do the same to place the No. 1 upper piston ring. Give at least 45° between the piston ring end gaps and the expander ring gap, so the gap is not placed on the piston pin center or at its thrust position.