JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 1500 Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Flywheels found

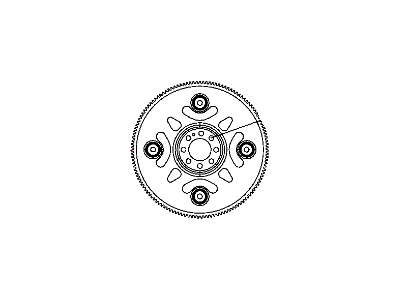

Dodge Ram 1500 Flywheel Part Number: 53022042AA

$198.28 MSRP: $293.00You Save: $94.72 (33%)Ships in 1-2 Business Days

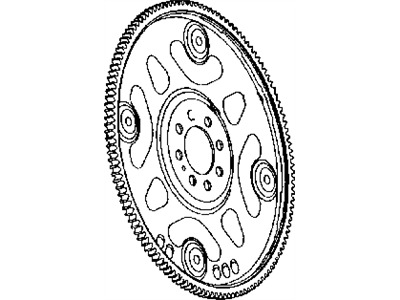

Dodge Ram 1500 Flywheel Part Number: 53020688AB

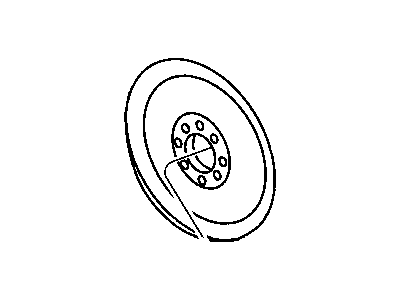

Dodge Ram 1500 Flywheel Part Number: 5037226AB

Dodge Ram 1500 Flywheel Part Number: 53020585

Dodge Ram 1500 Flywheel Part Number: 53020521

Dodge Ram 1500 Flywheel

Choose OEM Flywheel that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Flywheel follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 1500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 1500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

A critical component within the Dodge Ram 1500 operates as a reliable example of performance which supports vehicle efficiency along with safety functions. As a rotational energy reservoir the Flywheel manages power output smoothly until it operates the starter drive to start ignition processes while functioning as a friction component helping the clutch disc work. The Flywheel by Dodge functions as an essential component capable of preserving engine performance excellence across every model of the Ram 1500 even when these vehicles utilize solid flywheels or Dual Mass Flywheels (DMFs). The DMFs function as engineered vibration-absorbing components which provide improved driving comfort in diesel models of the Ram 1500 over other models. The Dodge engineers have highlighted Flywheel durability by solving breakdown factors affecting clutch surface friction and ring gear fracture that creates replacement needs. A Dodge Ram 1500 Flywheel delivers enhanced performance alongside reliable engine operation which makes the vehicle safer to drive. The automotive market recognizes the outstanding role of the Flywheel because it works with different Ram 1500 models while demonstrating exceptional engineering features that support truck operations. The Dodge Ram 1500 Flywheel stands as an exemplary quality statement of Dodge's dedication to vehicle excellence benefitting all owners who want reliable performance from their model.

Dodge Ram 1500 Flywheel Parts and Q&A

- Q: How to Properly Install and Secure a Flywheel on Dodge Ram 1500?A:Place the flywheel on the Crankshaft or adapter plate when installing it in a vehicle with a Dual Mass flywheel. Turn each flywheel bolt evenly using the proper torque which is 95 Nm (70 ft. lbs.) for any other flywheel and 55 Nm (40 ft. lbs.) for a Dual Mass Flywheel adapter plate. After that, install the clutch and then the transmission.

- Q: What Are the Best Practices for Servicing and Repairing a Flywheel on Dodge Ram 1500?A:Take out the transmission, the pressure plate and the clutch first, before starting to repair the flywheel. After that, withdraw the bolts holding the flywheel in place and remove it as well. Whenever the flywheel's surface is worn or chipped, arrange for it to be replaced with the whole assembly. Should the flywheel not be available, it's possible to install a replacement ring gear on only V10/Diesel Engines. Put a mark on the flywheel to show the old gear's position with the scriber. Then, cut the majority of the way through the gear with a cut-off abrasive wheel. You can then remove the rest with a cold chisel or punch. The ring gear goes on the flywheel as a shrink fit, so it must be heated up for the installation process. Heat the gear in an oven or comparable heating machine to obtain uniformity and avoid using a torch because this can spot heat or harm the flywheel by making it expand unevenly. Use heat-resistant gloves and safety goggles any time you handle the heated ring gear. Evenly fit the heated gear to the flywheel in a shop press, use proper press plates and after cooling in usual shop air, put the flywheel on a bench to install the ring gear only after it's fully cooled. Do not use any liquid or compressed air to cool the flywheel, as it could harm or damage the gear. First, attach the flywheel to the Crankshaft with the bolts tightened to 95 Nm (70 ft. lbs.), set the clutch in place and finish by fitting the transmission.