JeepParts

My Garage

My Account

Cart

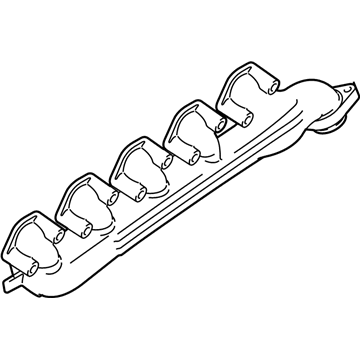

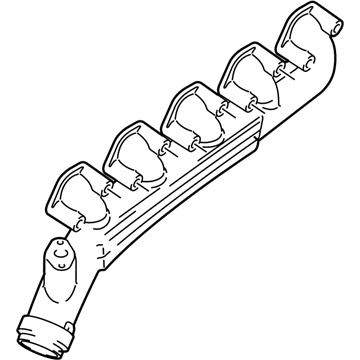

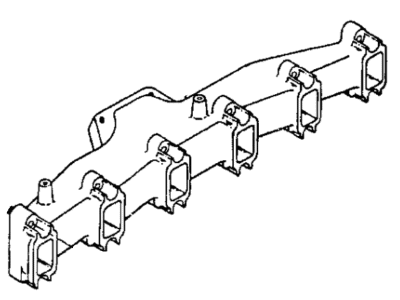

OEM Dodge Ram 3500 Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Exhaust Manifolds found

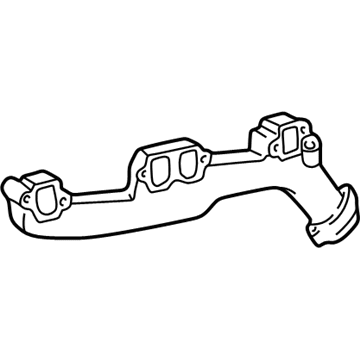

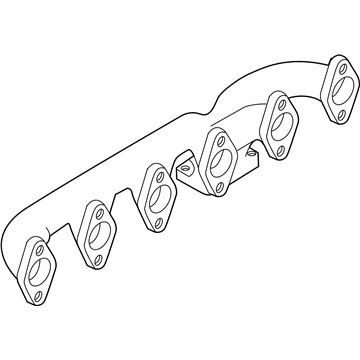

Dodge Ram 3500 Exhaust Manifold Part Number: 5014170AD

$386.52 MSRP: $816.00You Save: $429.48 (53%)

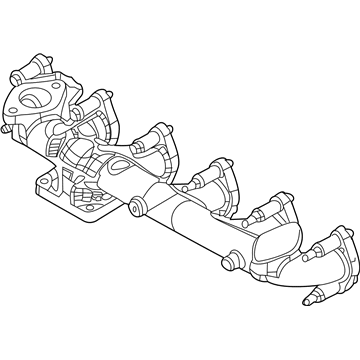

Dodge Ram 3500 Exhaust Manifold Part Number: 68002432AC

$721.55 MSRP: $1305.00You Save: $583.45 (45%)Ships in 1-2 Business DaysDodge Ram 3500 Exhaust Manifold, Driver Side Part Number: 53010189AB

$249.82 MSRP: $337.00You Save: $87.18 (26%)Ships in 1-2 Business Days

Dodge Ram 3500 Exhaust Manifold Part Number: 68210184AB

$546.17 MSRP: $802.00You Save: $255.83 (32%)

Dodge Ram 3500 Exhaust Manifold, Passenger Side Part Number: 68045560AB

$49.01 MSRP: $70.75You Save: $21.74 (31%)Dodge Ram 3500 Exhaust Manifold, Driver Side Part Number: 53032197AY

Dodge Ram 3500 Exhaust Manifold Part Number: 5011909AB

Dodge Ram 3500 Exhaust Manifold Part Number: 68045559BB

$40.60 MSRP: $59.60You Save: $19.00 (32%)Dodge Ram 3500 Exhaust Manifold, Driver Side Part Number: 53032149AC

Dodge Ram 3500 Exhaust Manifold Part Number: 53031401

Dodge Ram 3500 Exhaust Manifold, Passenger Side Part Number: 53010188

Dodge Ram 3500 Exhaust Manifold Part Number: 5086934AA

Dodge Ram 3500 Exhaust Manifold Part Number: 4429349

Dodge Ram 3500 Exhaust Manifold Part Number: 5135788AC

$525.56 MSRP: $771.00You Save: $245.44 (32%)

Dodge Ram 3500 Exhaust Manifold

Choose OEM Exhaust Manifold that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Exhaust Manifold follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

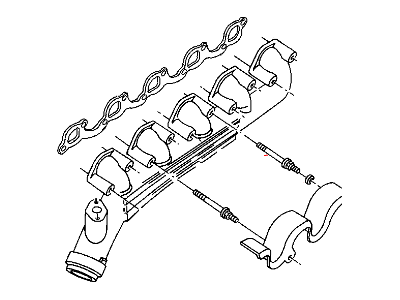

Exhaust Manifold of Dodge Ram 3500 helps in channelling hot exhaust gases coming from the engine to the exhaust system and as a result it helps to enhance the efficiency of the engine and minimize hazardous gases emissions. Located at the end of the exhaust chain, the manifold collects exhaust from numerous cylinders, normally formed of a complex of large, interlinking pipes with irregular size and material, including cast iron or stainless steel. There are a number of varieties of exhaust manifolds used in the Dodge Ram 3500 and these consist of standard manifolds as well as the headers. Unlike conventional manifolds that try to capture as much exhaust gases as possible, headers are built to offer as little opposition to the exhaust gas stream as possible while increasing the exhaust velocity. It is also very important to maintain the exhaust manifold in good condition, because if the unit gets bad, there could be decreased performance and incentives and dangerous materials could get out from the exhaust leak.

Dodge Ram 3500 Exhaust Manifold Parts and Q&A

- Q: How to Effectively Service and Repair an Exhaust Manifold on Dodge Ram 3500?A:When servicing or repairing an exhaust manifold, first pull out the battery negative terminals and put the car on a hoist. Remove the pipe from the turbocharger elbow on the exhaust and take out the toll drain tube, then lower the vehicle. Go ahead and disconnect the air inlet hose from the electronic wastegate command valve, the harness from the wastegate command valve and then unhook the air cleaner assembly. Detach the supply line bringing turbocharger oil and the charge air cooler pipe that goes into the turbocharger. Take off the turbocharger and gasket from above the exhaust manifold, then take the nuts from the cab heater return pipe out of the stud in the manifold before pushing the tube aside. Take off the heat shield, the bolt lockplates from the exhaust manifold and the exhaust manifold bolts and spacers. Scrape and clean the cylinder head and exhaust manifold sealing surfaces with either a scraper or a Scotch-Brite pad. See if there are any cracks in the exhaust manifold and measure it so that it doesn't deviate more than 0.20 mm (0.008 inch) from being flat. When installing, fit new gaskets between the exhaust manifold and engine head, after which you should proceed to bolt them on and tighten them to 43 Nm (32 ft. lbs.) in the instructed pattern. Replace the four center bolts, set the heat shield and torque nuts to 24 Nm (18 ft. lbs.) and apply the cab heater tube and exhaust manifold bolt retention straps. Place the cab heater return hose on the manifold bolt stud and tighten its nut to 24 Nm (18 ft. lbs.) torque. Assemble the turbocharger using a new gasket and use torque of 43 Nm (32 ft. lbs.) for the mounting nuts. Lift the vehicle once more and place the oil drain tube with a new gasket, tighten its bolts to 24 Nm (18 ft. lbs.). Connect the Exhaust Pipe to the turbo charger and fasten the bolts to 11 Nm (100 ft. lbs.) torque, then hook up the wastegate command valve and return the vehicle to the ground. Pour 50 to 60 cc (2 to 3 ounces) of clean engine oil into the oil supply line fitting on the turbocharger and use your hand to turn the turbocharger impeller until the oil is well distributed. Secure the oil supply line fitting nut to 24 Nm (18 ft. lbs.), put the charge air cooler inlet pipe on the turbocharger and clamp it with 11 Nm (95 inch lbs.) torque and then secure the air inlet hose to the turbocharger with a clamp tightened to 4 Nm (35 inch lbs.) torque. When everything is done, reconnect the car's negative Battery Cables and switch on the engine to examine the area for leaks.

- Q: How to Maintain and Fix an Exhaust Manifold on Dodge Ram 3500?A:For servicing or fixing the exhaust manifold, you must first remove its negative Battery Cables and hoist the car. Remove the Exhaust Pipe from the turbocharger elbow and lower the car once that is complete. After that, remove the hose for the turbocharger's air , the line for its oil , the oil drain tube and finally the charge air cooler's inlet pipe. Take out the turbocharger and gasket from the exhaust manifold, then remove the nut from the exhaust manifold stud that connects the cab heater return pipe. Once removed, place the pipe where it won't be in your way. After removing both bolts and spacers joining the exhaust manifold to the cylinder head, take out the manifold and its gaskets. Wipe down the areas where seals sit between the cylinder head and the exhaust manifold with a scraper and material like ScotchBrite. Search the exhaust manifold for cracks, then check if the ports are flat by putting a ruler over them all and inserting a feeler gauge. To install, apply new gaskets while connecting the exhaust manifold and others, then put the bolts and spacers in order, tightening each bolt to 43 Nm (32 ft. lbs.) torque. Put the cab heater return hose back onto the manifold bolt stud and torque the nut to 24 Nm (18 ft. lbs.). Place the turbocharger in position and tighten the nuts that hold it to 32 Nm (24 ft. lbs.). Insert the removed drain tube and oil supply line into the turbocharger and tighten the drain tube bolts to 24 Nm (18 ft. lbs.) torque. Squirt 2 to 3 ounces (50 to 60 cc) of engine oil into the oil supply line of the turbocharger and turn the impeller with your hand to spread the oil. Turn the oil supply line fitting nut down the required 20 Nm (133 inch lbs.). Guide the charge air cooler inlet pipe to fit the turbocharger and tighten its clamp nut until you reach 8 Nm (72 inch lbs.) and repeat this for the air inlet hose and its clamp. Place the vehicle up on the hoist and join the end of the exhaust pipe to the turbocharger, then tighten the bolts to 34 Nm (25 ft. lbs.) of torque. Move the vehicle down, link the black battery negative cables back and see if any fluid leaks out when the engine is running.