JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 3500 Fan Clutch

Cooling Fan Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Fan Clutches found

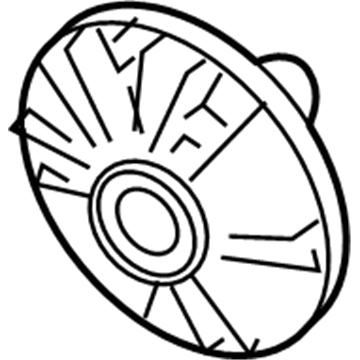

Dodge Ram 3500 Fan Clutch Part Number: 55056990AC

$625.17 MSRP: $911.00You Save: $285.83 (32%)

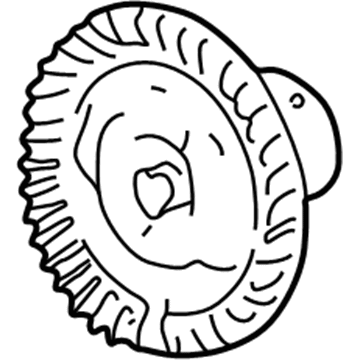

Dodge Ram 3500 Fan Clutch Part Number: 68064765AA

$185.81 MSRP: $274.00You Save: $88.19 (33%)Ships in 1-2 Business Days

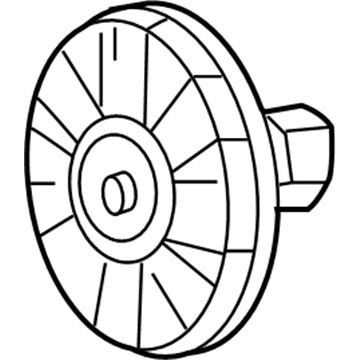

Dodge Ram 3500 Fan Clutch Part Number: 52028879AF

$613.72 MSRP: $895.00You Save: $281.28 (32%)

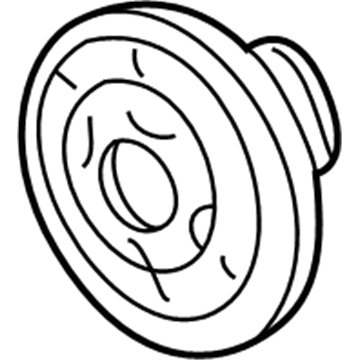

Dodge Ram 3500 Fan Clutch Part Number: 52028877AC

$227.73 MSRP: $335.00You Save: $107.27 (33%)Ships in 1-2 Business Days

Dodge Ram 3500 Fan Clutch Part Number: 52029876AC

$175.62 MSRP: $259.00You Save: $83.38 (33%)Ships in 1-2 Business DaysDodge Ram 3500 Fan Clutch Part Number: 52027882AB

$92.46 MSRP: $117.21You Save: $24.75 (22%)Ships in 1-2 Business Days

Dodge Ram 3500 Fan Clutch Part Number: 68155609AB

Dodge Ram 3500 Fan Clutch Part Number: 55056963AB

Dodge Ram 3500 Fan Clutch Part Number: 52029400AA

Dodge Ram 3500 Fan Clutch Part Number: 55057152AA

Dodge Ram 3500 Fan Clutch Part Number: 52029300AE

Dodge Ram 3500 Fan Clutch Part Number: 55057153AA

Dodge Ram 3500 Fan Clutch Part Number: 52029860AC

Dodge Ram 3500 Fan Clutch Part Number: 52027885

Dodge Ram 3500 Fan Clutch Part Number: 52027710AB

Dodge Ram 3500 Fan Clutch

Choose OEM Fan Clutch that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Fan Clutch follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

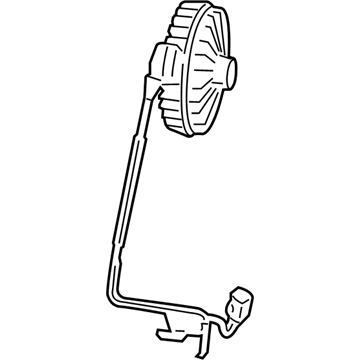

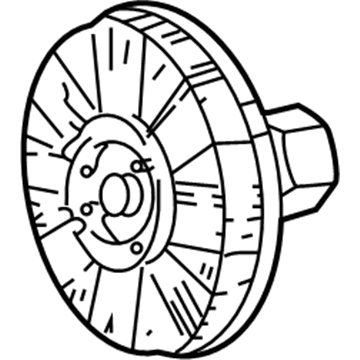

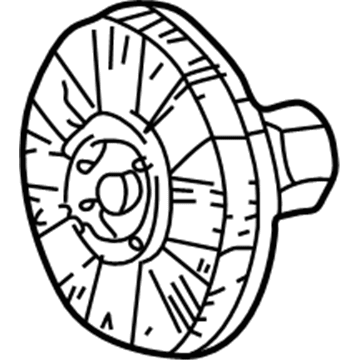

Dodge Ram 3500 fan clutch is a device that can be viewed as completely reliable and offering good performance on the automotive market. This Fan Clutch is manufactured uniquely for the Dodge Ram 3500 and it has a central function of controlling the operation of the cooling fan in order to manage the levels of heat that the vehicle's engine produces effectively. Due to the fan speed control feature of the Dodge Ram 3500 Fan Clutch in conformity with the engine temperature and speed, this auto part enhances the performance and durability of the vehicle. Applicable to different versions of Ram 3500, this Fan Clutch is usually assembled on the water pump pulley and activated by the crankshaft of the engine for efficient cooling in various conditions. The Dodge Ram 3500 Fan Clutch comes in different types: viscous and electronically controlled types to give different amounts of control and efficiency, thus making it a major selling point. This flexibility, though contributing positively to the efficiency of the vehicle also has a very important contribution to safety since it helps to prevent engine overheating. In terms of durability, the reliability of Dodge Ram 3500 Fan Clutch adds to such notion due to its ability to support a high-profiled usage. In general, the Dodge Ram 3500 Fan Clutch is an essential part that adds value to the Ram 3500 model and further establishes the vehicle of being one of the best full size pickup trucks in the market.

Dodge Ram 3500 Fan Clutch Parts and Q&A

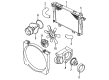

- Q: How to Maintain and Fix a Fan Clutch on Dodge Ram 3500?A:Before servicing the fan clutch, start by removing the battery negative cables and taking out the fan shroud bolts, placing the shroud beside the top of the engine while the fan pulley bolts stay where they are. Attached to the fan hub shaft is the thermal viscous fan drive/blade assembly; to remove it, turn the mounting nut clockwise as its threads turn Left-hand. A Snap-On 36 Mm Fan Wrench called Sp346, found in the Snap-On Cummins Diesel Tool Set 2017Dsp, is suitable and a bar or screwdriver should remain between the fan pulley bolts. Both the fan shroud and fan assembly should now be out, so remove all four bolts from the Fan Blade/viscous fan drive mounting and check the fan for any cracks, loose rivets or bent blades. Some engines with serpentine belts use reverse rotating fans and viscous fan drives that have the word Reverse on the casing; switching the fan or drive to the opposite end can cause engine overheating. Gentle soap and water are the right cleaners to use when cleaning fan blades. After changing the fan assembly because of mechanical damage, check the Water Pump and viscous fan drive for possible damage caused by shaking the assembly. With a flat screwdriver, push each bolt of the blade assembly out, then remove the fan; lay it with the leading edge down on a flat surface and if there is more than 2.0 mm (0.090 inch) clearance on either side or if any rocking motion is seen, replace the fan. Look over the fan assembly for any damage such as cracks, bends, loose rivets or broken welds; if there is any harm, change the part. During installation, fixed the fan blade assembly on the viscous fan drive, tightening the bolts to 23 Nm (17 ft. lbs.) torque. Place the fan shroud and the fan blade or viscous fan drive into one assembly, fit the viscous fan drive assembly onto the fan hub shaft and secure it with a mounting nut tightened to 57 Nm (42 ft. lbs.) torque. Tighten all the fan shroud bolts to 6 Nm (50 inch lbs.) torque and then hook up the negative cables on the battery once more. When the new viscous fan drive is installed, increase engine speed to 2000 rpm and hold for about two minutes to ensure the fluid is distributed inside it.