JeepParts

My Garage

My Account

Cart

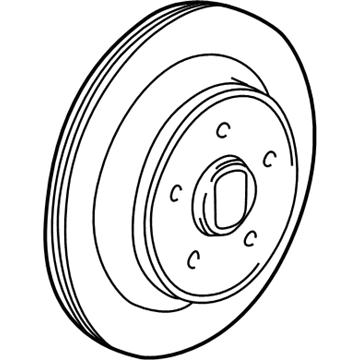

OEM Dodge Ram 3500 Van Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Discs found

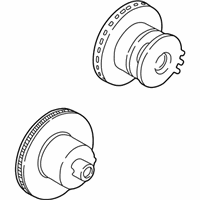

Dodge Ram 3500 Van Rotor, Rear Part Number: 52010362AA

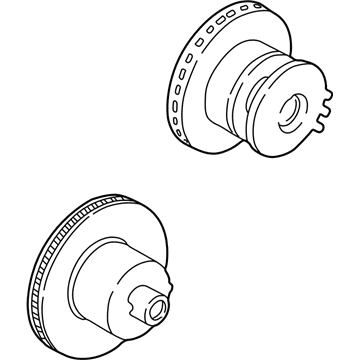

$74.86 MSRP: $94.90You Save: $20.04 (22%)Ships in 1-2 Business DaysDodge Ram 3500 Van Hub & Rotor, Front Part Number: 52009414AB

$81.94 MSRP: $103.87You Save: $21.93 (22%)Ships in 1-2 Business DaysDodge Ram 3500 Van Hub & Rotor, Front Part Number: 52009414

$87.25 MSRP: $110.61You Save: $23.36 (22%)Ships in 1-2 Business DaysDodge Ram 3500 Van Hub & Rotor, Front Part Number: 52009415AC

Dodge Ram 3500 Van Brake Disc

Choose OEM Brake Disc that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Brake Disc follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 Van matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 Van parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Ram 3500 Van Brake Disc Parts and Q&A

- Q: How to service and repair the Brake Disc on Dodge Ram 3500 Van?A:When servicing the brake disc, first support the car, then take off the wheel and tire. After that, detach the caliper and make sure it does not remain suspended by the hose. Take out the bolts from the caliper adapter and take off the adapter from the steering knuckle. Remove the grease cap, cotter pin, nut lock, nut, washer and outer wheel bearing, then the disc from the spindle. For the install, look over and repack the wheel bearings if needed and set new grease seals in place if the inner bearing came off. If your vehicle has an ABS system, check the tone wheel in the disc hub. If the teeth are worn, the whole disc and hub assembly has to be changed since there is no way to replace just the tone wheel. Once the hub/disc is on, fit the outer wheel bearing, a washer and a retaining nut. While rotating the hub/disc, fasten the nut to 41 - 54 Nm (30 - 40 ft. lbs.), then hold it still and loosen the nut to end the bearing preload torque. Screw on the nut firmly by hand, mount the nut lock and secure again with a new cotter pin, ensuring the end play fits within 0.25 - 0.076 mm (0.001 - 0.003 inch). Clean the grease cap, rub the inside with wheel bearing grease and then install it. Make sure the caliper adapter is secure; tighten its bolts to either 176 Nm (130 ft. lbs.) on LD 1500 models or 285 Nm (210 ft. lbs.) for HD 2500/3500 models. Next, insert the caliper with the bolts torqued to 33 Nm (24 ft. lbs.), replace the wheel and tire and only then bring the car down. Next, use the brake pedal a few times to properly position the brake shoes and give you a firm pedal before driving the car.

- Q: What Are the Essential Steps and Equipment for Machining a Scored or Worn Brake Disc on Dodge Ram 3500 Van?A:Problems such as too much wear or scoring on the disc brake disc mean it needs to be machined and this requires a lathe with cutters on both heads. You should wipe the disc mounting place clean before putting the disc on, as some machines may result in tapered discs if it is dirty. For best results, use a hub-mounted on-vehicle lathe since it can correct any problems between the disc and vehicle hub/bearing. Discs that are too thin according to the standards, even after machining, should be discarded.