JeepParts

My Garage

My Account

Cart

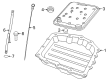

OEM Dodge Stratus Automatic Transmission Filter

AT Filter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Automatic Transmission Filters found

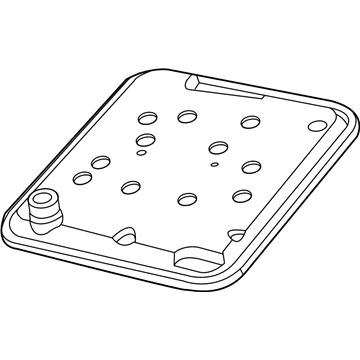

Dodge Stratus Auto Transmission Filter Part Number: 4864505AB

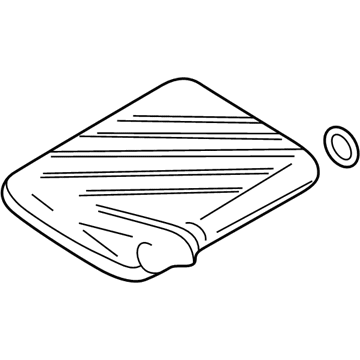

$44.78 MSRP: $66.80You Save: $22.02 (33%)Ships in 1-2 Business DaysDodge Stratus Filter Part Number: MD758684

Dodge Stratus Automatic Transmission Filter

Choose OEM Automatic Transmission Filter that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Automatic Transmission Filter follows strict manufacturing steps to lock in quality and fit. If your Dodge Stratus matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Stratus parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Dodge Stratus Automatic Transmission Filter is one of the crucial parts that boosts the strength of the Dodge Stratus and stability of the transmission system. Famous for its capturing capabilities for all contaminants, this Automatic Transmission Filter helps in preventing the circulation of contaminants in the transmission hence protecting the required system from possible destruction and facilitation of a smooth run. For the use on many different 1995-2005 Dodge Stratus models, this filter's location is conveniently tucked behind the - transmission fluid pan, so it is very easy to get to when it comes time to check it. Dodge Stratus Automatic Transmission filter enhances the filtration level but also enhances the transmission of the oils and this function enhances the fuel rate hence benefitting on fuel economy and on the same note the shelf life span of the transmission. This is especially so with vehicle owners who would wish to conduct their activities in a cost efficient manner while at the same time ensuring safety on the roads. The filter has recommend features installed on it to elevate its performance from those of ordinary filters in the automobile sector. Thus, by using the Dodge Stratus Automatic Transmission Filter, the driver will benefits from a cleaner transmission and consequently, an enhancement of the vehicle's performance. This essential component is greatly advantageous to the Dodge Stratus which has powerful engine options as well as its smooth acceleration; therefore, it would be a great investment for economical drivers who seek reliability and performance. All in all, the Dodge Stratus automatic transmission filter is a very important part of the Dodge Stratus because it keeps the Dodge Stratus running in a very powerful way for many years.

Dodge Stratus Automatic Transmission Filter Parts and Q&A

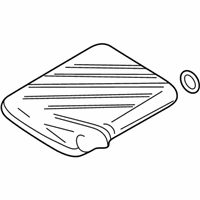

- Q: How to Service an Automatic Transmission Filter According to the Owner's Manual on Dodge Stratus?A:Review the manual of your vehicle for the best suggested maintenance timing for the transaxle's fluid and filter service. Use leopard ATF +4 and exchange the filter at the same time. If the transaxle is apart, wipe the magnet clean and change both the fluid and the filter when replacing the fluid. The first step is to jack up the car, put a container below the Oil Pan and drain the oil. Loose the bolts on the pan, tap one part to get the drain hole unstuck and pull out the oil pan to let the fluid drain. Replace the filter and O-ring on the bottom of the valve body, clean both the oil pan and magnet, use new Mopar Silicone Adhesive to install the oil pan tightening to 19 Nm (165 in. lbs.). Send four quarts of Mopar Type 9602 ATF +4 down the dipstick hole, start the engine and leave it running for one minute. Put both your parking and service brakes on, move the selector lever to each setting several times and set the selector to either park or neutral. Measure the transaxle fluid and make sure it is 3 mm (1/8 inch) below the lowest mark on the dipstick, then recheck the level once the transaxle is not hot, usually when it falls to about 83°C (180°F). Put the dipstick entirely in the hole to avoid letting dirt in the transaxle. When using the fluid suction method, the transaxle has to be fully warm, you have to use an appropriate device and ensure the suction line is in the dipstick tube all the way to the lowest part of the oil pan. Open the drain plug, empty the old fluid, remove the suction line, then pour four quarts of Mopar ATF +4 (Automatic Transmission Fluid) Type 9602 through the dipstick as needed, after which you start the engine. Remember to return the dipstick, check and adjust the fluid level and make sure it's fully seated to complete the steps.

- Q: How to Maintain and Repair an Automatic Transmission Filter on Dodge Stratus?A:Before servicing the fluid filter for the automatic transmission, use only Original Mopar ATF +4 (Automatic Transmission Fluid) Type 9602. Filter replacement should happen whenever your transmission oil is changed and cleaning the magnet inside the Oil Pan is done best with a clean dry cloth. If you remove the transaxle, replace both the fluid and the filter. Raise the vehicle on a hoist and set a drain container beneath the transaxle oil pan. Work the bolts loose, tap at least one side corner and then drain the liquid into a container before taking out the oil pan. Set a new filter and O-ring on the bottom of the valve body, clean the oil pan and magnet and attach the pan again using new Mopar Silicone Adhesive sealant, made sure the final tightness of the bolts is 19 Nm (165 in. lbs.). Put four quarts of Mopar ATF +4 through the dipstick opening, start the engine and let it run for at least one minute. With the parking and service brakes set, engage each position of the selector lever, until you are in park or neutral. Measure the amount of transaxle fluid and then add some if it is below the lowest mark on the dipstick, 3 mm (1/8 inch) from flush. Retest the level once the transaxle has reached normal operating temperature (180°F). Pull the dipstick out and place it correctly to avoid dirt debris from reaching the transaxle. When using the dipstick tube fluid suction method, let the transaxle warm up to operating temperature, use the right device for suction and push the suction line into the dipstick tube to the very bottom of the oil pan. Once you've taken out the suction line, place four quarts of Mopar ATF +4 through the dipstick tube, start the engine and test the fluid level again, making sure the dipstick is properly seated.