JeepParts

My Garage

My Account

Cart

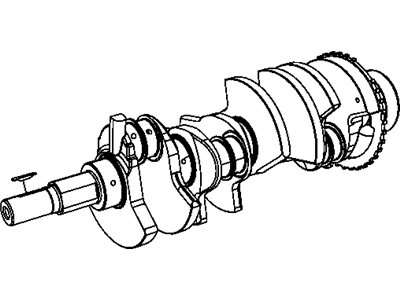

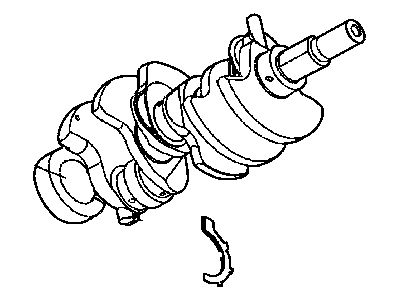

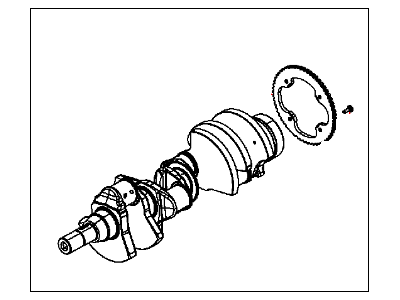

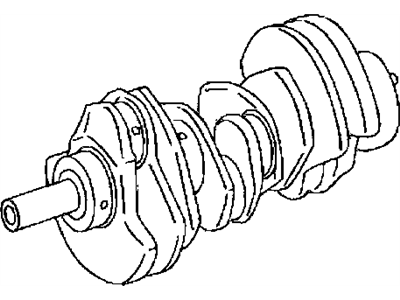

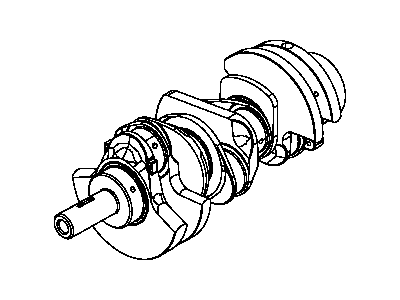

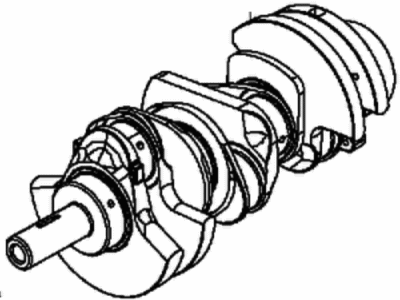

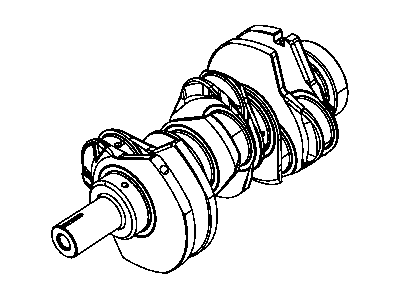

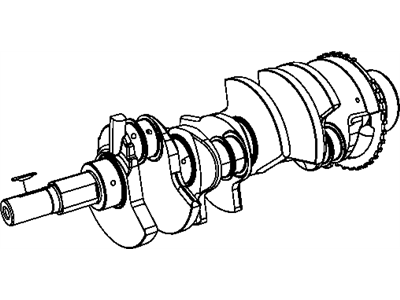

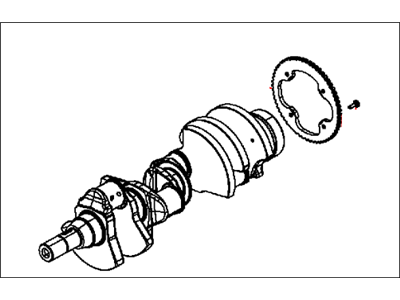

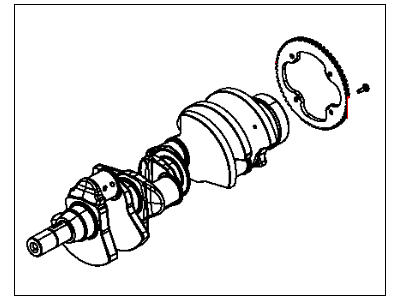

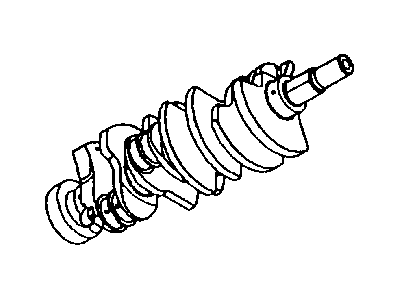

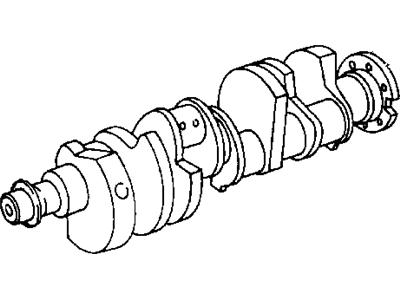

OEM Jeep Grand Cherokee Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

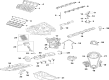

19 Crankshafts found

Jeep Grand Cherokee Crankshaft Part Number: 53021302BC

$833.71 MSRP: $1105.00You Save: $271.29 (25%)Ships in 1-2 Business Days

Jeep Grand Cherokee Crankshaft Part Number: 53020959AB

$629.85 MSRP: $959.00You Save: $329.15 (35%)Ships in 1-2 Business DaysJeep Grand Cherokee Crankshaft Part Number: 5038339AG

$956.93 MSRP: $1455.00You Save: $498.07 (35%)Jeep Grand Cherokee Crankshaft Part Number: 68136832AB

$443.12 MSRP: $2810.00You Save: $2366.88 (85%)Ships in 1-2 Business DaysJeep Grand Cherokee Crankshaft Part Number: 5184251AI

$570.18 MSRP: $860.00You Save: $289.82 (34%)Ships in 1-2 Business DaysJeep Grand Cherokee Crankshaft Part Number: 68253313AB

$392.74 MSRP: $572.00You Save: $179.26 (32%)Ships in 1-2 Business DaysJeep Grand Cherokee Crankshaft Part Number: 4893950AC

$616.59 MSRP: $930.00You Save: $313.41 (34%)Ships in 1-2 Business Days

Jeep Grand Cherokee Crankshaft Part Number: 68147110AB

Jeep Grand Cherokee Crankshaft Part Number: 53022286AA

Jeep Grand Cherokee Crankshaft Part Number: 53021302AD

Jeep Grand Cherokee Crankshaft Part Number: 5037458BD

Jeep Grand Cherokee Crankshaft Part Number: 53021302BB

$215.27 MSRP: $317.00You Save: $101.73 (33%)Jeep Grand Cherokee Crankshaft Part Number: 53021387AA

Jeep Grand Cherokee Crankshaft Part Number: 4893356AA

Jeep Grand Cherokee Crankshaft Part Number: 4864726AD

Jeep Grand Cherokee Crankshaft Part Number: 68498568AA

$1688.88 MSRP: $2490.00You Save: $801.12 (33%)Jeep Grand Cherokee Crankshaft Part Number: 68293005AB

$1015.62 MSRP: $1505.00You Save: $489.38 (33%)Jeep Grand Cherokee Crankshaft Part Number: 53021407AA

Jeep Grand Cherokee Crankshaft Part Number: 53020603

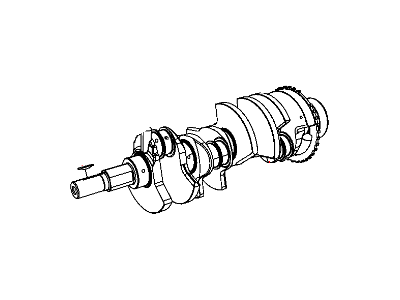

Jeep Grand Cherokee Crankshaft

Choose OEM Crankshaft that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Crankshaft follows strict manufacturing steps to lock in quality and fit. If your Jeep Grand Cherokee matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Grand Cherokee parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Jeep Grand Cherokee Crankshaft Parts and Q&A

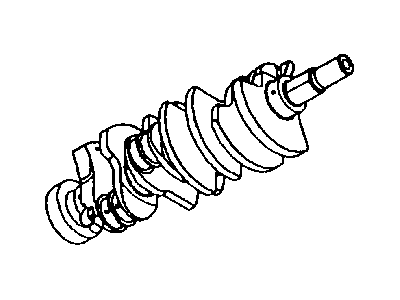

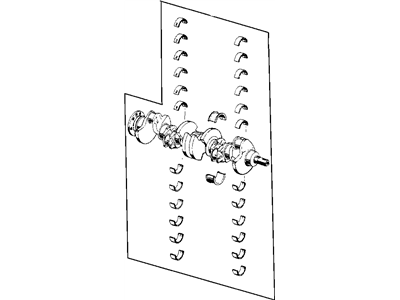

- Q: How to Properly Install a Crankshaft on Jeep Grand Cherokee?A:If you are installing the crankshaft, check that the main bearings are right for the task and always be careful to not damage the bearing surfaces on the shaft. Coat sealant on all retaining screws connecting the tone wheel before beginning the job. Brush on some clean engine oil to the upper main bearing halves, slide in the crankshaft into the cylinder block and place the thrust washers over the crankshaft. Both surfaces where the bedplate meets the cylinder block should be covered with Mopar(R) Engine RTV sealant to avoid serious oil leaks and possible distortion of the main bearings. Past a 2.5mm (0.100 inch) layer of Mopar(R) Engine RTV sealant onto the cylinder block-to-bedplate joining point, cover the main crankshaft bearings with engine oil and set the bedplate onto the cylinder block. Apply a little clean engine oil to each bedplate retaining bolt before installation and then position the stud bolts correctly before securing them. Hand tighten bolts 1D, 1G and 1F to make the bedplate touch the block, then use a torque wrench to tighten bolts 1A - 1J to 54 Nm, bolts 1 - 8 to 7 Nm, turn them an extra 90° and tighten bolts A - E to 27 Nm. Check the side play of the crankshaft, put in the connecting rods and measure the clearance at the sides. After that, install the oil pump and the engine.

- Q: How is the Crankshaft Removed from the Engine on Jeep Grand Cherokee?A:The crankshaft can be removed after taking out the engine from the car and removing the engine oil pump. The oil pan gasket must not be pried because it is secured to the cylinder block at three points and will not unscrew when the pan is removed. Following that, get rid of the bedplate mounting bolts, make a note of where the two stud bolts should go and take out the connecting rods, making certain you do not hurt the sealing surface between the bedplate and cylinder block. Because the lower main bearing halves are in the bedplate, you should handle it gently to not fall on them since an improper installation might seriously harm the crankshaft. Lift the bedplate using the cast pry points and once done, remove the crankshaft and the crankshaft tone wheel. If you notice scoring, blueing or heavy scratches inside the connecting rod bearing bores or main bearing bores, extra disassembly may be required. When the bearing bores in the connecting rods are damaged, taking off the cylinder heads is necessary to replace the piston and rod assemblies; damaged bedplate or cylinder block bores call for a new engine. If desired, separate the two main bearing pieces from the front of the cylinder block and main bedplate, clear them of debris, clean all the bearing faces and bores inside the engine and examine the bedplate bore for possible cracks or scoring. Inspect the thrust washers of the crankshaft and look for any splits or visible damage on the oil pan gasket/windage tray. Care should be taken not to harm the bearing surfaces and sealant should be applied to the tone wheel retaining screws before mounting the crankshaft. Apply clean engine oil to the upper main bearing halves, put the crankshaft tone wheel in place and tighten the mounting screws to 15 Nm (11 ft. lbs.). Place the crankshaft in the cylinder block, put the thrust washers on and coat the contact surface area of the bedplate to block with Mopar Engine RTV to avoid leaks. Apply a 2.5 mm (0.100 inch) amount of sealant to the engine block where the bedplate will sit, rub a thin layer of clean oil on the crankshaft journals and set the bedplate on the block. All bedplate retaining bolts should be lubricated with clean engine oil before you install them and as you install them, check that stud bolts are where they are supposed to be and use the correct torque sequence. Place bolts 1D, 1G and 1F until the bedplate touches the block before securing bolts 1A to 1J to 54 Nm, measuring by Nm or ft. lbs. Then, turn bolts 1 - 8 to 7 Nm, 90° further and finish with bolts A - E, set to 27 Nm. First, check the crankshaft end play, then add the connecting rods, measure side clearance and add the oil pump and engine.