JeepParts

My Garage

My Account

Cart

OEM 2001 Chrysler Sebring A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 A/C Clutches found

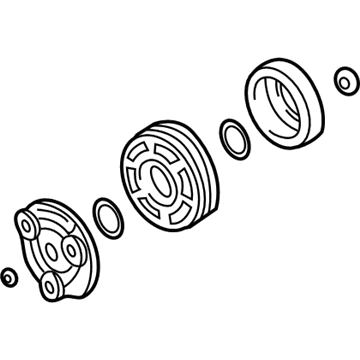

2001 Chrysler Sebring Clutch Part Number: MR500339

$74.98 MSRP: $95.05You Save: $20.07 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch - A/C Compressor; A/C Compressor Clutch; Clutch A/C Compressor

- Item Weight: 4.00 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: MR500339

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Chrysler Sebring Clutch Assembly Part Number: 5018772AA

Product Specifications- Other Name: Clutch - A/C Compressor; Clutch Overhaul Kit A/C Compressor

- Item Weight: 4.60 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5018772AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Chrysler Sebring Clutch Assembly Part Number: 5018771AA

Product Specifications- Other Name: Clutch - A/C Compressor; Clutch Overhaul Kit A/C Compressor

- Item Weight: 4.60 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5018771AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Chrysler Sebring Clutch Part Number: MR500254

Product Specifications- Other Name: Clutch - A/C Compressor; A/C Compressor Clutch; Clutch A/C Compressor

- Item Weight: 3.60 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: MR500254

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

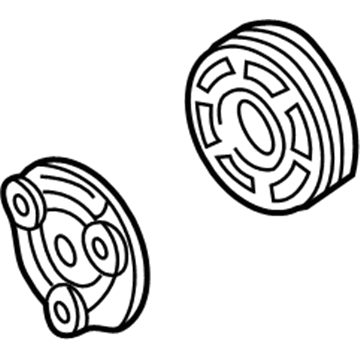

2001 Chrysler Sebring Pulley Part Number: MR500233

Product Specifications- Other Name: Clutch Package - A/C Compressor; A/C Compressor Clutch Pulley; Rotor And Armature A/C Compressor

- Item Weight: 2.70 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: MR500233

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Chrysler Sebring Pulley Part Number: MR460108

Product Specifications- Other Name: Clutch Package - A/C Compressor; A/C Compressor Clutch Pulley; Rotor And Armature A/C Compressor

- Item Weight: 2.60 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: MR460108

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

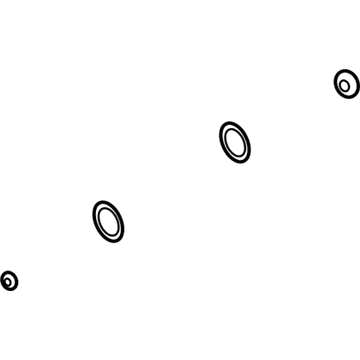

2001 Chrysler Sebring Repair Kit Part Number: MR315936

Product Specifications- Other Name: Clutch Package - A/C Compressor; Clutch Overhaul Kit A/C Compressor; Clutch A/C Compressor

- Item Weight: 0.50 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: MR315936

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Chrysler Sebring A/C Clutch Parts and Q&A

- Q: How to Service an A/C Clutch on 2001 Chrysler Sebring?A: Keep in mind, you must unhook and separate from the car the negative terminal on the battery and then remove the serpentine belt to service the compressor clutch. Take out the wire connector connecting the compressor clutch coil to the compressor and disconnect the four attachment bolts. Hold the compressor as you take it out of its mounting bracket. With C-4489, turn two ends parallel to each other in a counterclockwise direction to hold the clutch plate while removing the nut. After that, use Puller C-6461 to take out the clutch plate and then remove the compressor shaft key and clutch shims. Slide the snap ring pliers beneath the outside housing snap ring, followed by placing the Rotor Puller (C-6141-1) into the snap ring next to the one you removed and then attach the Shaft Protector (C-6141-2). Place the Puller Bolts C-6461 through the puller flange into the jaw of the rotor puller and keep turning the puller center bolt clockwise until the rotor pulley comes off. Remove the screw and retainer from the clutch coil wire harness in front of the compressor, then pull off the snap ring from the hub of the compressor and slide away the clutch field coil. To install the clutch, mount the clutch field coil and snap ring first, add the clutch coil wire retaining clip to the front of the compressor and tighten the screw. Place the rotor assembly directly on the compressor housing hub and use Installer C-6871 to put in the pulley bearing assembly by turning the nut until the pulley is seated. With the bevel part facing the outside, install the external snap ring fully so as to avoid problems with the clutch or compressor. Then, put the compressor shaft key and original clutch shims on the compressor shaft, fit the clutch plate with Driver C-6463 and tighten the shaft nut to 14.4 Nm (10.5 ft. lbs.). Put a feeler gauge between the clutch disc and flywheel to measure the air gap and correct the shims if necessary so the gap is 0.41 - 0.79 mm (0.016 - 0.031 in.). When the air gap isn't steady, carefully pry or tap the string up or down. When installing a clutch for the first time on a compressor, apply one shim size: 1.0, 0.50 or 0.13 mm (0.040, 0.020 or 0.005 in.). Put the compressor in place on the bracket, tighten its bolts to 41 Nm (30 ft. lbs.), wire the compressor clutch harness and replace the serpentine drive belt. To finish, start the engine, make sure the car is in A/C mode, allow the blower fan to run on high, create 20 cycles by turning the clutch on and off for 5 seconds, then off for another 5 seconds, while the engine runs at approximately 1500-2000 rpm-only do this for new clutches.