JeepParts

My Garage

My Account

Cart

OEM 2002 Dodge Neon Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Brake Master Cylinders found

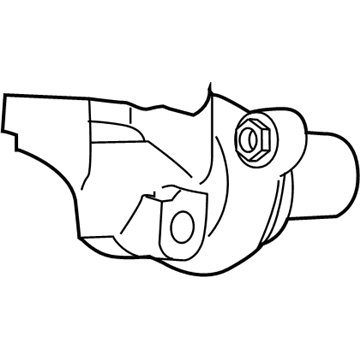

2002 Dodge Neon Master Cylinder Part Number: 5015149AB

$204.84 MSRP: $336.00You Save: $131.16 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Master Cylinder - Brake; Brake Master Cylinder

- Replaces: 5015149AA

- Item Weight: 2.80 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5015149AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Dodge Neon Master Cylinder Part Number: 5015160AA

$243.26 MSRP: $308.38You Save: $65.12 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Master Cylinder - Brake; Brake Master Cylinder; Master Cylinder Brake

- Item Weight: 2.40 Pounds

- Item Dimensions: 13.3 x 6.8 x 4.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5015160AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

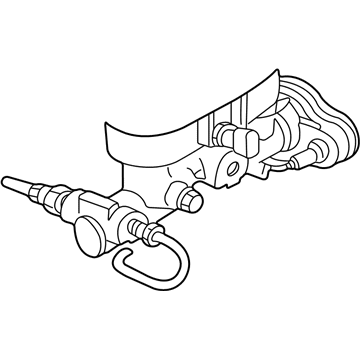

2002 Dodge Neon Master Cylinder Part Number: 5069001AA

Product Specifications- Other Name: Master Cylinder - Brake; Brake Master Cylinder; Master Cylinder Brake

- Item Weight: 2.40 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5069001AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Dodge Neon Brake Master Cylinder Parts and Q&A

- Q: How to Service and Repair a Brake Master Cylinder Without ABS on 2002 Dodge Neon?A: First pump the vacuum in the brake booster by pumping the the brake pedal a few times with the engine off until the pedal is firm, then proceed with the service on your LHD vehicle without ABS. Take off the negative cable from the battery, place the battery somewhere safe and then detach the positive cable. After that, secure the battery with the nut on the backside. Unplug the brake fluid level switch wire harness connector from inside the master cylinder reservoir first. Then remove both brake tubes from the master cylinder and from the proportioning valves, placing plugs into each open outlet on the master cylinder. Surface clean the area that links the master cylinder to the booster, then unscrew the two bolts that hold the master cylinder in place and simply pull it out. Each proportioning valve should be unscrewed from the master cylinder before it is removed. Bleed the master cylinder before starting the installation and, afterward, line up the installed proportioning valves with their correct ports, then add new O-rings to them. Make sure the O-ring vacuum seal on the master cylinder is unobstructed, replacing it if so and clean off the front of the power brake booster. Set the master cylinder on the booster's studs, ensure the push rod is aligned and gently move it to the booster so it touches the face. Tighten the master cylinder mounting nuts to a torque of 18 Nm (160 in. lbs.) and after connecting all brake tubes to their proper ports on the master cylinder and valve, tighten them to a torque of 17 Nm (145 in. lbs.). Reattach the brake fluid level switch's wiring connector, slot in the battery and fix it and lastly join the positive and negative cables. Screw in the master cylinder until it is full, work the brake pedal several times and check the amount of brake fluid, making changes as required. If there is air in the brake system for a long period or the lines are filled with air, you should drain all of the base hydraulic system. Next, look for leaks and make a test drive to verify that the brakes are working correctly.