JeepParts

My Garage

My Account

Cart

OEM 2003 Dodge Neon Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Brake Master Cylinders found

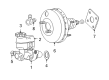

2003 Dodge Neon Master Cylinder Part Number: 5015149AB

$204.84 MSRP: $336.00You Save: $131.16 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Master Cylinder - Brake; Brake Master Cylinder

- Replaces: 5015149AA

- Item Weight: 2.80 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5015149AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

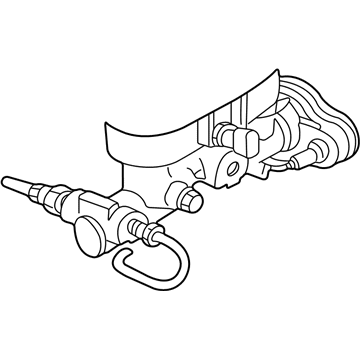

2003 Dodge Neon Master Cylinder Part Number: 5015160AA

$243.26 MSRP: $308.38You Save: $65.12 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Master Cylinder - Brake; Brake Master Cylinder; Master Cylinder Brake

- Item Weight: 2.40 Pounds

- Item Dimensions: 13.3 x 6.8 x 4.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5015160AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

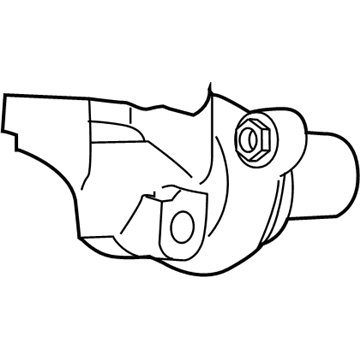

2003 Dodge Neon Master Cylinder Part Number: 5069001AA

Product Specifications- Other Name: Master Cylinder - Brake; Brake Master Cylinder; Master Cylinder Brake

- Item Weight: 2.40 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5069001AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Neon Brake Master Cylinder Parts and Q&A

- Q: How to Service and Repair a Brake Master Cylinder on 2003 Dodge Neon?A: Before servicing or repairing the brake master cylinder on a LHD vehicle with ABS, first depress the brake pedal 4-5 times, with the engine off, to pump down the power brake booster's vacuum. Separate the ground cable from the negative terminal on the battery and isolate it and next disconnect the positive terminal and get the battery out of the tray by fixing it to the back with a nut. Separate the brake fluid level switch wiring harness from the master cylinder reservoir and unhook both the primary and secondary brake tubes from the top of the master cylinder. Then, fit plugs into the hole in the reservoir outlet. Rinse the space around the master cylinder and booster attachment using a good brake cleaner. Open the panel housing and then loosen the master cylinder by unscrewing the two nuts and remove the master cylinder straight out. Bleed the master cylinder and see if the rear mounting flange O-ring needs to be replaced, if it is damaged. Do not allow any cleaner or debris into the booster by first thoroughly cleaning the seal area where the master cylinder connects to the face of the booster. Place the master cylinder on the center studs of the power brake vacuum booster, align the push rods and lightly push it until it meets the booster's face. Screw on the two mounting nuts until you reach a torque of 18 Nm (160 inch lbs.) Then, join the primary and secondary brake tubes to the master cylinder and tighten their nuts to 17 Nm (145 inch lbs.). Attach the wiring harness to the master cylinder reservoir fluid level switch, put the battery and clamp back and fasten the positive and negative batteries. Sustain full pressure to the reservoir, press the pedal a few times and check the fluid level and make necessary adjustments. If air has been in the brake system for too long or can be seen in the lines, bleed all the base hydraulic parts. Also, review the vehicle for possible leaks and conduct a highway test to test both systems.