JeepParts

My Garage

My Account

Cart

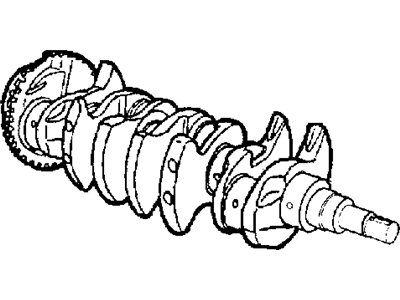

OEM 2003 Chrysler PT Cruiser Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

2003 Chrysler PT Cruiser Crankshaft Part Number: 4781643AA

$539.13 MSRP: $818.00You Save: $278.87 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft Includes Target Ring And Screw

- Item Weight: 47.80 Pounds

- Item Dimensions: 24.5 x 8.8 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4781643AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Chrysler PT Cruiser Crankshaft Parts and Q&A

- Q: How to Remove and Reinstall a Crankshaft in an Engine Assembly on 2003 Chrysler PT Cruiser?A: The crankshaft can only be removed after the engine and transaxle are disconnected from inside the vehicle. After that, take the flex plate and rear oil seal from the crankshaft and mount the engine on a repair stand. Pour out the engine oil and take out the oil filter and now take off the oil pan and engine mount support bracket. You should remove the noise-insulating crankshaft damper, the timing belt covers, the timing belt, the crankshaft sprocket and the oil pump. Cylinder head removal is needed if you must replace the piston or connecting rod. Pen or paint mark each rod cap instead of stamping them to reduce the likelihood of damage. Unscrew all the connecting rod bolts and remove their caps, without harming the fracture rod and cap surfaces and don't reuse the connecting rod bolts. Come out the bedplate bolts from the engine block, then carefully hammer at the bedplate to remove it from the dowel pins without damage. Turn the crankshaft clockwise and lift it out without touching either the main bearings or journals. Make sure to inspect crankshaft journals and that any wear, taper or scoring stays within manufacturer's taper and round levels and that the grinding does not exceed 0.305 mm (0.012 inch) under the standard journal diameter. With a bolt, insert and run every main bearing up to the stop, without turning the crank, so as not to damage the your main bearing or pin. Set the upper shells of the main bearings in the cylinder block, oil grooves facing down and make sure the holes in the cylinder are lined up with the holes in the bearings. Keep oil away from the bedplate mating surface, grease the bearings and journals and mount the crankshaft using just the given brand of anaerobic sealer. Plaster a bead of Mopar Bed Plate Sealant onto the cylinder block, slide the lower main bearings into the main bearing cap or bedplate and make sure the bearing tabs are inside the slots. Put the main bearing/bedplate into the engine block, grease the bolts and screw them in gently before closing them up to their final position. Rotate the crankshaft until the number 4 piston arrives at TDC, move it rearward and forward to see how far it will travel and wedge a tool between the rear crankshaft counterweight and the rear of the cylinder block to keep it in the forward position. Tighten the bolts using a sequence to 41 Nm (30 ft. lbs.), then set aside the wedge tool and repeat the tightening to 41 Nm, plus a final tightening to 75 Nm (55 ft. lbs.). Place main bearing bedplate to engine block bolts and tighten each to 28 Nm (250 inch lbs.) one at a time, repeating this step. After installing the main bearing bedplate, look at the torque that the crankshaft turns with, since it should not exceed 5.6 Nm (50 inch lbs.). After placing connecting rod bearings and caps, do not reuse the bolts, but set them so they are torqued to 27 Nm (20 ft. lbs.) plus 1/4 turn. If the balance shafts, housing, oil pump and cylinder head were removed, replace these parts now. Once done, secure the timing belt rear cover, crankshaft sprocket, timing belt, timing belt front covers, engine mount support bracket, oil pan, oil filter, crankshaft rear oil seal and flex plate, putting Mopar Lock & Seal Adhesive on bolt threads and tightening each to 95 Nm (70 ft. lbs.). Screw on the bolts to attach the transaxle to the engine, making sure they are tightened to 101 Nm (75 ft. lbs.). Afterward, set the engine assembly into place.