JeepParts

My Garage

My Account

Cart

OEM 2003 Dodge Durango Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Rod Bearings found

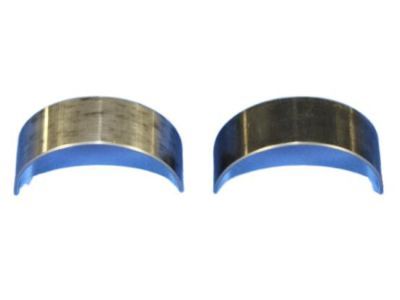

2003 Dodge Durango Bearings Part Number: 5012363AE

$16.87 MSRP: $25.00You Save: $8.13 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing - Connecting Rod; Rod Bearing; Bearing Kit Connecting Rod Standard See Note; Bearing Kit Connecting Rod Standard

- Replaces: 5012363AC, 5012363AD, 5018584AB, 5012363AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 4.0 x 2.7 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5012363AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

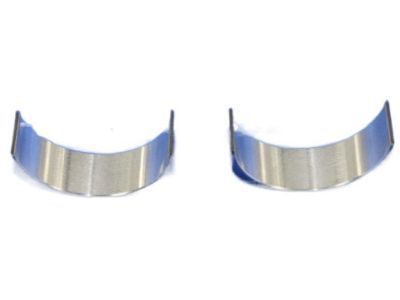

2003 Dodge Durango Rod Bearings Part Number: 2421305

$17.58 MSRP: $22.29You Save: $4.71 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing Package - Connecting Rod; Engine Connecting Rod Bearing; Connecting Rod Bearing Pair; Rod Bearing; Bearings; Connecting Rod Bearing Package, Standard; Includes various connecting rod bearings.

- Item Weight: 0.50 Pounds

- Item Dimensions: 4.2 x 3.1 x 1.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 2421305

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Durango Rod Bearing Parts and Q&A

- Q: What Are the Best Practices for Inspecting and Installing Rod Bearings on 2003 Dodge Durango?A: Examine the connecting rod bearings for scratches, bent alignment tabs and normal signs of wear, along with scoring, grooving and pitting. Substitute any bearing that looks badly worn. Inspect the journals of the connecting rod for signs of scoring, nicks and burrs. A misalignment or bend in a connecting rod can result in unusual damage to the pistons, piston rings, cylinder walls, rod bearings and crankshaft rod journals. When you notice strong wear or damage that may come from an incorrectly aligned connecting rod, inspect the rod for correct alignment and replace it if it is bent or twisted. Take off the excess oil on the connecting rod journal, lightly oil the upper bearing insert and place it in the connecting rod. Use the piston ring compressor and the Guide Pins Special Tool 8507 to put in the rod and piston assemblies, so that the oil slinger slots in the rods are toward the front of the engine and the "F's" near the piston bore are pointing forward. First, install the base bearing insert into the bearing cap if it's dry, then put a strip of Plastigage from end to end over the middle of the lower insert. Thread the bearing cap and connecting rod onto the journal, screwing the bolts to 27 Nm (20 ft. lbs.) and then turn them a 90° extra. After removing the bearing cap, measure the compressed Plastigage's width to check that the bearing-to-journal clearance is the same across the insert. A variable clearance could show a tapered journal, a bent connecting rod or loose debris trapped between the insert and cap or rod. If the color of the Plastigage matches the recommended clearance, continue the installation and remove the Plastigage. In case the bearing-to-journal gap is larger than allowed, choose a bearing set according to the given size requirements. Measuring Plastigage a second time will help confirm the correct bearing has been chosen before assembly. Choose the correct insert, secure it and add the cap to the connecting rod hole, turning the bolts until they reach 27 Nm (20 ft. lbs.), plus 90 degrees of tightening. Place a feeler gauge snugly in between the connecting rod and crankshaft journal flange and if the side clearance falls outside the required value, change the connecting rod.