JeepParts

My Garage

My Account

Cart

OEM 2004 Chrysler Concorde Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Pistons found

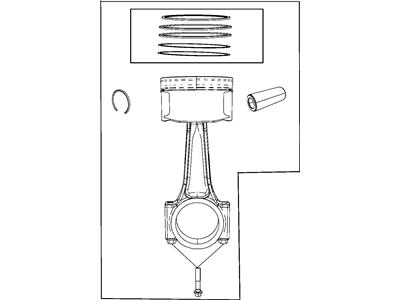

2004 Chrysler Concorde Piston Part Number: 5018627AD

$316.65 MSRP: $576.00You Save: $259.35 (46%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Pin And Rod; Piston Pin And Rod

- Replaces: 5018627AB, 5018627AA, 5018627AC

- Item Weight: 2.60 Pounds

- Item Dimensions: 13.3 x 5.2 x 4.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5018627AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

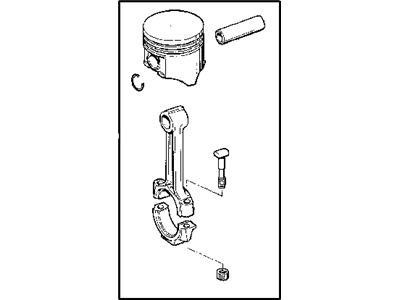

2004 Chrysler Concorde Piston Part Number: R5010335AB

Product Specifications- Other Name: Piston Pin And Rod

- Replaces: 5010335AB

- Item Weight: 3.10 Pounds

- Item Dimensions: 12.9 x 5.8 x 4.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: R5010335AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Chrysler Concorde Piston Parts and Q&A

- Q: How Are Pistons and Connecting Rods Removed and Installed in an Engine on 2004 Chrysler Concorde?A: The ridge need to be cut first, covering the tops of the pistons while you use a ridge reamer for the cylinder bores. Before removing the assemblies, make sure the top of the cylinder block has been lowered far enough so connecting rods are centered in their respective cylinders. Mark where the connecting rod and bearing caps are meant to go using a scribe or permanent marker and take care not to damage the cracked areas on the rod or cap. Take out the connecting rod cap and insert Special Tool 8189 Connecting Rod Guides into the rod you are removing. Next, pull out each piston and rod assembly from the cylinder bore, not scratching the crankshaft journals. Put the bearing cap back on the mating rod as soon as the bearing is removed, to prevent damage to the broken surfaces. Make sure the piston rings are installed, the compression ring gaps do not line up and the oil ring expander ends fit under the rail properly. Dip the piston head and rings into clean engine oil, slip the ring compressor over the piston, use the special wrench to secure it, before you check the positions of the rings do not change. Let the shaft of the bearing half axis up through the connecting rod, grease the bearing cone with clean oil and install Special Tools 8189 Connecting Rod Guides into the connecting rod. An arrow and "F" (Front) above the pin boss on the piston indicate its direction which should be pointed toward the front of the engine on each side, so the rod oil hole faces the block's major thrust side. Work the crank so that the center of the journal in the connecting rod lines up with the center of the cylinder bore, put the rod and piston in and place the rod over the journal on the crankshaft. Press the piston down into the cylinder bore using a hammer handle and, as you do that, guide the connecting rod into place on the journal. Give the rod bolts and the bearing area a coating of engine oil, then fit the cap and fixing bearing tightening the bolts to 28 Nm (21 ft. lbs.) plus another quarter turn.