JeepParts

My Garage

My Account

Cart

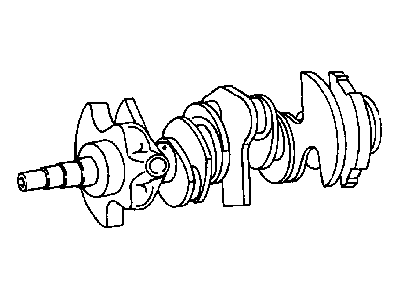

OEM 2004 Chrysler Pacifica Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

2004 Chrysler Pacifica Crankshaft Part Number: 4792692AB

Product Specifications- Other Name: Crankshft

- Replaces: 4792692AC, 4792177, 4792692AA

- Item Weight: 56.60 Pounds

- Item Dimensions: 22.3 x 8.4 x 7.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4792692AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Chrysler Pacifica Crankshaft Parts and Q&A

- Q: How to Service and Repair a Crankshaft on 2004 Chrysler Pacifica?A: To service and repair the crankshaft, firstly remove the engine out of the vehicle and then remove the oil pan, oil pickup tube, the front timing belt cover, timing belt and tensioner as well as the crankshaft sprocket. and knock the dowel pin out of the crankshaft, the oil pump assembly, and crankshaft rear oil seal retainer. The bearing caps should never be stamped with a metal stamp, but a scribe or paint mark should be used, connecting rod bearing caps are not interchangeable and should be marked prior to removal. Likewise, main bearing cap is not inter-changeable but requires marking to be used correctly. With the crankshaft removed from the cylinder block examine the crankshaft journals, checking out excessive wear, taper and scoring with a limit of 0.015 mm (0.0006 inch) on taper or out of round and 0.305 mm (0.012 inch) below the standard journal diameter on journal grinding. The thrust faces of the Number 2 main bearing should not be ground, nor the crank pin nor bearing fillets nicked, and after grinding all the passages should be cleaned and the rough edges of the crankshaft oil holes rucked. When fitting the crankshaft is most important that the upper main bearing fit squarely into the oil holes in the cylinder block. Rotate the crankshaft to the far right and lube and fit the front thrust washer then back out to fit the rear thrust washer. Reseat the lower main bearings in the main bearing caps, clean engine oil lubricate the main bearing cap bolts and then lubricate the lower main bearings. Turn each main cap and bolts following the appropriate sequence, beginning at the inner main cap bolts, then the windage tray bolts and the last should be the main cap tie bolts. Torque the inside main bearing cap bolts to 20 Nm 1/4 turn, check the crank shaft end play, fit the connecting rods and measure the side clearance. Fix the windage tray, grease the bolts down and fasten them at 27 Nm plus 1/4. The main cap tie bolts should be tightened up to 28 Nm (250 inch lbs.), with the rear crankshaft oil seal retainer and oil seal being installed after this step, and the oil pump assembly. Reinstall the dowel pin into crankshaft, crankshaft sprocket, and the timing belt and tensioner, and front timing belt cover. Reconnect the oil pickup tube attaching the nut to 28 Nm (250 inch lbs.), then reconnect the oil pan and engine assembly and lastly fill the engine crankcase with the desired quantity of oil.