JeepParts

My Garage

My Account

Cart

OEM 2005 Chrysler 300 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Discs found

2005 Chrysler 300 Rotor, Rear Part Number: 68368070AA

$91.83 MSRP: $151.00You Save: $59.17 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor - Brake; Disc Brake Rotor, Rear; Disc Brake Rotor; Brake Rotor

- Position: Rear

- Replaces: 4779208AD, 4779208AG, 4779208AE, 4779208AH, 4779208AC, 4779208AB, 4779208AF

- Item Weight: 16.40 Pounds

- Item Dimensions: 3.3 x 13.1 x 13.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68368070AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Chrysler 300 Rotor, Rear Part Number: 68368071AA

$116.51 MSRP: $189.00You Save: $72.49 (39%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor - Brake; Disc Brake Rotor, Rear; Disc Brake Rotor; Brake Rotor

- Position: Rear

- Replaces: 4779209AB, 68368072AA, 4779209AE, 4779209AC, 4779209AD, 4779209AG, 68241042AA, 4779209AF, 68241042AB

- Item Weight: 19.70 Pounds

- Item Dimensions: 13.4 x 2.7 x 13.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 68368071AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

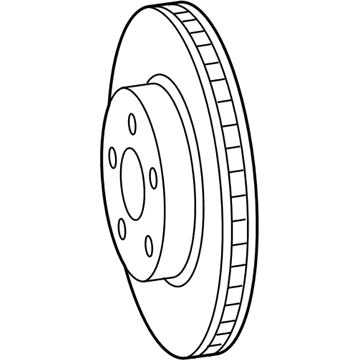

2005 Chrysler 300 Rotor, Front Part Number: 68368064AA

$98.15 MSRP: $152.00You Save: $53.85 (36%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor - Brake; Disc Brake Rotor, Front; Disc Brake Hardware Kit; Brake Rotor

- Position: Front

- Replaces: 4779196AE, 4779196AF, 4779196AD, 4779196AG, 4779196AB

- Item Weight: 20.20 Pounds

- Item Dimensions: 2.3 x 13.2 x 12.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68368064AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

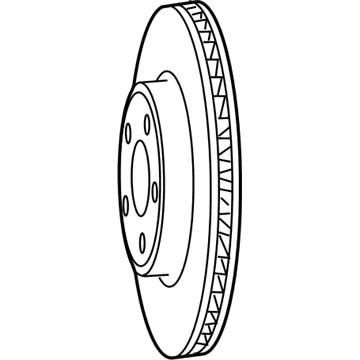

2005 Chrysler 300 Rotor, Front Part Number: 68368065AA

$118.69 MSRP: $192.00You Save: $73.31 (39%)Product Specifications- Other Name: Rotor - Brake; Disc Brake Rotor, Front; Disc Brake Hardware Kit; Disc Brake Rotor; Brake Rotor

- Position: Front

- Replaces: 5154118AB, 4779197AC, 4779197AF, 4779197AB, 4779197AG, 5154118AC, 4779197AD, 5154118AA, 4779197AE, 5154118AD

- Item Weight: 23.50 Pounds

- Item Dimensions: 2.6 x 14.0 x 14.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68368065AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Chrysler 300 Brake Disc Parts and Q&A

- Q: Should You Reface the Brake Disc with Every Brake Pad Replacement on 2005 Chrysler 300?A: Brake discs are usually fine with every pad change, though they should be refaced when the surface is damaged, scratched and especially if customers say the brakes produce a rougher, vibrating feeling. If you notice this, reface the disc on a car with a hub-mounted on-car brake lathe or replace it. To minimize runout, special attention is given to using a hub-mounted on-car brake lathe that attaches the disc directly to the center of the wheel hub and bearing. Each brake disc has a marking for the minimum allowable thickness, either cast straight onto the surface or stamped onto the hat section and the specification table has the allowable details. Never machine a disc below the least thickness indicated by the minimum allowable thickness. Before mounting the lathe, look to make sure that the brake disc face and hub adapters are clean and have no chips or rust. When mounting and using the brake lathe, follow exactly the steps provided by the manufacturer. When machining a brake disc, the front and back should be done at the same time to avoid uneven cuts. The refacing process needs to keep the required TIR (Total Indicator Reading) and thickness ranges safe which demands that disc turning equipment is carefully controlled, following the indicated specifications from the specification table.