JeepParts

My Garage

My Account

Cart

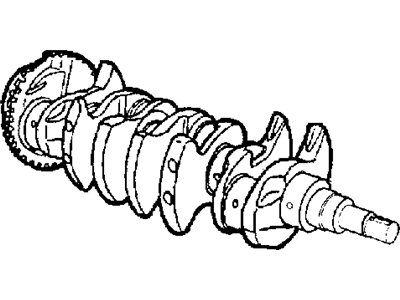

OEM 2005 Chrysler PT Cruiser Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

2005 Chrysler PT Cruiser Crankshaft Part Number: 4781643AA

$539.13 MSRP: $818.00You Save: $278.87 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft Includes Target Ring And Screw

- Item Weight: 47.80 Pounds

- Item Dimensions: 24.5 x 8.8 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4781643AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Chrysler PT Cruiser Crankshaft Parts and Q&A

- Q: How to Remove and Install a Crankshaft in an Engine Assembly on 2005 Chrysler PT Cruiser?A: The first thing to do is remove the engine from the vehicle, then disconnect the transaxle from the engine to take out the crankshaft. Next, the drive plate/flex plate and the crankshaft's rear oil seal should be removed and lift the engine onto a repair stand. Remove the engine oil and take off the oil filter, then get rid of the crankshaft vibration damper, engine mount support bracket, front timing belt covers, timing belt, rear timing belt cover and oil pan. Taking out the oil pump pick-up tube, crankshaft sprocket, oil pump, balance shafts and housing assembly and crankshaft position sensor is required. Removing the cylinder head becomes necessary when piston or connecting rod replacement is called for. Label each connecting rod cap with permanent marker instead of using a number stamp or punch to protect the surface. Remove all connecting rod bolts and caps, being careful not to do any damage to the fracture rod and cap and never reuse the connecting rod bolts. Pull all the bolts out of the bed plate area and then evenly hit the bedplate against the dowel pins to loosen and remove it. Be sure not to harm the man bearings or journals when taking out the crankshaft and leave the target ring brackets screwed in until you remove the ring. Look for excessive wear and bending, along with notched or scratched tools, on the crankshaft journals so that the difference in roundness or taper doesn't go beyond 0.025 mm and that the journal grinding doesn't reach more than 0.305 mm below the standard round diameter. The thrust faces of the No. 3 main bearing shouldn't be ground and care needs to be taken so the crank pin and bearing fillets are not nicked. Grind away any burrs on the oil holes after grinding and carefully clean all inside passages so that the crankshafts keep their normal direction of fine-finishing in rotation. It is important that the upper and lower bearing halves not be swapped, with the side drilled for the oil hole and groove in the engine. The main bearings of the crankshaft are five and the upper bearing halves within the crankcase have oil holes and grooves, just as do all the other lower halves except for the thrust bearing. Put the main bearing upper shells with the groove and hole for oil onto the engine block, making sure the oil hole in the shell is lined with the one in the engine. Oil on the bed plate mating surface can spoil the sealing process. After machine work on the crankshaft, the whole assembly-target ring and cranksha-must be balanced together. Clean the crankshaft and target ring with Mopar Brake Parts cleaner and afterwards dry them with compressed air. Use fresh mounting screws for the target ring, first hand tighten them in the first position (#1) and then use a T30 torx bit to tighten every screw to reach 13 Nm (110 inch lbs.) per the order shown in the manual. Coat bearings and journals in oil and then put the crankshaft into the engine assembly; make sure to add a 1.5 to 2.0 mm (0.059 to 0.078 inch) bead of sealant to the bed plate. Install both main bearing caps/bed plates into the main bearings, so the tabs are in place and set the bed plates into the engine block. Coat the bolts with oil, then attach the main bearing cap/bed plate to the engine block with your fingers before tightening them, slowly until the plate rests on the cylinder block. To correctly align the thrust bearings, turn the crankshaft while watching the number 4 piston approach top dead center. Then, move the crankshaft forward and backward to the maximum extent and hold it there using a tool that you slide in between the back of the cylinder block and the counterweight. Torque all the bolts in order to 41 Nm (30 ft. lbs.), take out the wedge tool and tighten the bolts once more to that same torque. Put in and torque the main bearing bed plate to engine block bolts to 28 Nm (250 inch lbs.), then tighten them once more to 75 Nm (55 ft. lbs.) and afterwards once more to 28 Nm (250 inch lbs.). Once the main bearing bed plate is put on, look to see whether obsvereda turning torque matched the required amount and whether there is harmless end wobble on the crankshaft. Set the rod bearings and caps into the crankshaft, don't reuse the connecting rod bolts and tighten them to 27 Nm (20 ft. lbs.) plus 1/4 turn. Secure the balance shafts and the housing assembly, the oil pump and the oil pump tube with a torque of 23 Nm (200 inch lbs.). Set up the oil pan, crankshaft position sensor and cylinder head if it was taken out. Replace the timing belt rear cover, front crankshaft oil seal, crankshaft sprocket, timing belt and the two timing belt covers in the front. After that, fix the engine mount support bracket and crankshaft vibration damper and then insert the new oil filter. Now detach from the repair stand, set the engine on the Dolly and Cradle, safeguard it with straps, add the rear oil seal for the crankshaft, seal and insert the flex or drive plate, use Mopar Lock & Seal for all bolts and fix everything to a torque of 95 Nm (70 ft. lbs.). Attach the engine to the transaxle and tighten the joining bolts at 101 Nm (75 ft. lbs.).