JeepParts

My Garage

My Account

Cart

OEM 2005 Dodge Ram 1500 Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Rod Bearings found

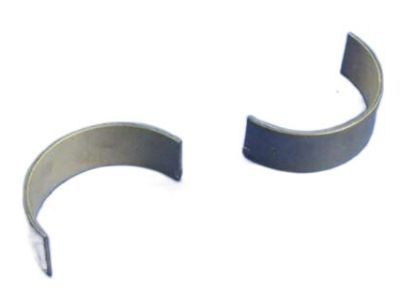

2005 Dodge Ram 1500 Connecting Rod Bearing Part Number: 68207790AA

$6.32 MSRP: $7.70You Save: $1.38 (18%)Product Specifications- Other Name: Bearing Package - Connecting Rod; Rod Bearing; Bearing; Bearings; Bearing Kit Connecting Rod Standard

- Replaces: 5086003AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 3.8 x 2.6 x 1.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 10

- SKU: 68207790AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

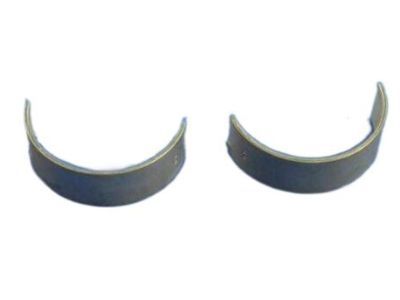

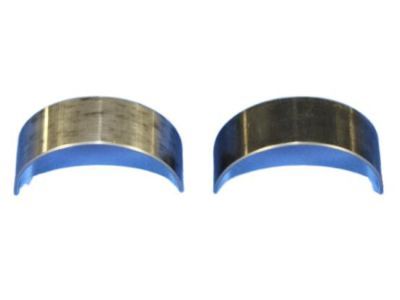

2005 Dodge Ram 1500 Bearings Part Number: 68052222AB

$18.13 MSRP: $26.80You Save: $8.67 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing - Connecting Rod; Engine Connecting Rod Bearing Set; Connecting Rod Bearing Set; Rod Bearing; Bearing Kit Connecting Rod Standard See Note

- Replaces: 5019447AA, 68052222AA

- Item Weight: 0.50 Pounds

- Item Dimensions: 3.9 x 2.6 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 6

- SKU: 68052222AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

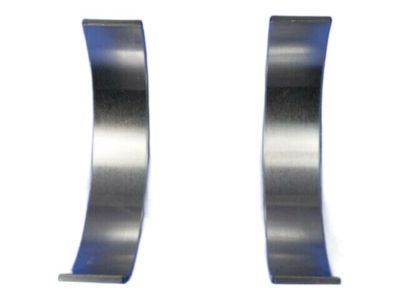

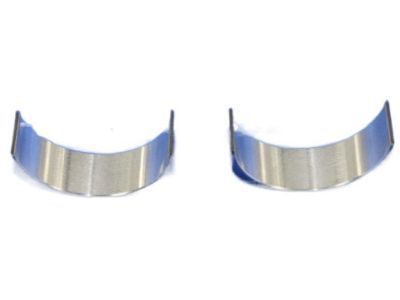

2005 Dodge Ram 1500 Bearings Part Number: 5012363AE

$16.87 MSRP: $25.00You Save: $8.13 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing - Connecting Rod; Rod Bearing; Bearing Kit Connecting Rod Standard See Note; Bearing Kit Connecting Rod Standard

- Replaces: 5012363AC, 5012363AD, 5018584AB, 5012363AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 4.0 x 2.7 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5012363AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Dodge Ram 1500 Rod Bearing Parts and Q&A

- Q: How to Inspect and Replace Rod Bearings on 2005 Dodge Ram 1500?A: Look at the connecting rod bearings to check for scoring, common wear markings, grooves, signs of damage and pitting; discard and replace any showing these signs. Make sure the journals on the connecting rods do not have any scoring, nicks or burrs, because even slightly misaligned rods can lead to unusual wear on the pistons, piston rings, cylinder wall and crankshaft connecting rod bearings. If checks around the connecting rod suggest its alignment is off, check for any irregularities or damage and replace any that seem misaligned or bent. First, clean off the oil on the rod journal, then grease the top bearing insert and fit it into the connecting rod so that it is centered. With the Guide Pins Special Tool 8507, use the piston ring compressor to install the rod and piston assemblies, bringing the slingers in the rods around to the front and having the "F"'s forward on the piston wrist pin bore. Put the lower bearing ring into the bearing cap, center it and check that it is dry. Lay a strip of Plastigage down the whole center section of the lower insert underneath the bearing cap, so it does not crumble; if the strip breaks easily, use fresh stock. Once the bearing cap and rod are installed, tighten their bolts to 27 Nm (20 ft. lbs.) plus any extra turn, before rotating the crankshaft to prevent smudging the Plastigage. By using a ruler, identify the bearing clearance from the compressed Plastigage and make certain it is under the maximum approved limit. If the reading is within specifications, you can remove the Plastigage and complete installation; if it doesn't meet them, replace your thrust bearing set and discard the old connecting rod bolts, since they can only be used once. Measure Plastigage samples again before assembly to check the bearing choice and after installing the ring, tighten the connecting rod bolts to 27 Nm (20 ft. lbs.) and make an extra 90° turn. At last, place a properly sized feeler gauge between the connecting rod and crankshaft journal flange, making sure the clearance meets the guidelines and replace the connecting rod if it does not match.