JeepParts

My Garage

My Account

Cart

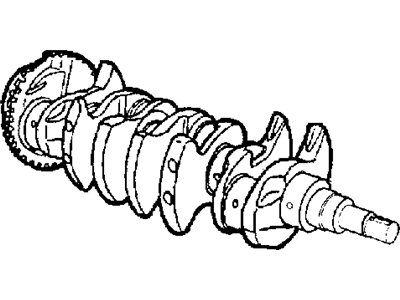

OEM 2007 Chrysler PT Cruiser Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

2007 Chrysler PT Cruiser Crankshaft Part Number: 4781643AA

$539.13 MSRP: $818.00You Save: $278.87 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft Includes Target Ring And Screw

- Item Weight: 47.80 Pounds

- Item Dimensions: 24.5 x 8.8 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4781643AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2007 Chrysler PT Cruiser Crankshaft Parts and Q&A

- Q: How Is a Crankshaft Installed and What Are the Key Steps Involved on 2007 Chrysler PT Cruiser?A: Supporting the crankshaft are five main bearings and all oil grooves and holes in the upper bearing shells of the crankcase can be found alongside those in the lower ones. Tightening of the outside crankshaft end play is maintained by a flanged bearing on the number three main journal bearing. Begin your process by putting in the main bearing upper shells, with the lubrication groove and oil hole in the engine block, so the oil holes are matched and the bearing tabs fit into the block tab slots. Make sure the bed plate mating surface is clean, as oil may make the sealer ineffective. When a crankshaft goes for machining, it is important to insert the target ring and balance them together. Clean the crankshaft and the target ring with Brake Parts Cleaner from Mopar(R) and afterward dry them by blowing compressed air. Use fresh mounting screws and start with #1 while tapping them into place finger tight, so the ring fits properly. Screw in all the torx screws with 110 inch-pounds (13 Nm) force in the proper order. Remember to apply oil to the bearings and journals before you set the crankshaft in the engine block and anaerobic sealer only on the bed plate to avoid damaging the engine. Line the bed plate with Mopar(R) Bed Plate Sealant and put the lower main bearings between the main bearing cap/bed plate. Make sure the bearing tabs are in the bed plate slots before slotting the main bearing/bed plate into the engine block. Go ahead and oil locks 11, 17 and 20 with clean engine oil. Put them in place and screw them finger tight until the bed plate touches the cylinder block. Turn the crankshaft until the number 4 piston reaches the top point of its cycle, then gently pull the crankshaft to its back limit and push it forward to its front limit. Finally, wedge an appropriate tool between the block and the counterweight to keep the crankshaft forward. Replace the wedge tool and tighten bolts 1 through 10 to 41 Nm (30 ft. lbs), then take it out again and tighten the same bolts to the same torque. Secure the main bearing bed plate to engine block bolts 11 through 20 to 28 Nm (250 in. lbs.) before making sure bolts 1 through 10 are secured to 75 Nm (55 ft. lbs.) and bolts 11 through 20 are fastened to 28 Nm (250 in. lbs.). With the main bearing bed plate installed, test that the turning torque is no greater than 5.6 Nm (50 in. lbs.) and examine the crankshaft end play. Fit and fasten the connecting rod bearings and caps, but don't use the bolts a second time; torque them to be 27 Nm (20 ft. lbs.) plus 1/4 turn. Now, install the balance shafts and housing, mount the oil pump and fit the oil pump pick-up tube, fastening these with 23 Nm (200 in. lbs.) of torque. Set the oil pan, crankshaft position sensor and cylinder head in place and then the timing belt rear cover, front crankshaft oil seal, crankshaft sprocket, timing belt and timing belt front covers. Installing the engine mount support bracket and crankshaft vibration damper should happen before you put in the new oil filter. With the engine separated from the repair stand, put it in place on Dolly 6135 and Cradle 6710, using safety straps to secure it. Then, fit the crankshaft rear oil seal, attach the drive plate/flex plate with Mopar(R) Lock & Seal Adhesive onto the bolts, tighten the bolts to 95 Nm (70 ft. lbs.), set the transaxle onto the engine with bolts tightened to 101 Nm (75 ft. lbs.) and finalize by fitting the engine assembly.