JeepParts

My Garage

My Account

Cart

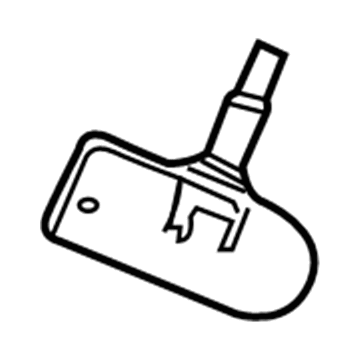

OEM 2008 Chrysler Pacifica TPMS Sensor

Tire Pressure Monitoring System Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 TPMS Sensor found

2008 Chrysler Pacifica TPMS Sensor Part Number: 68078861AC

$106.43 MSRP: $161.00You Save: $54.57 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor - Tire Pressure; Tire Pressure Monitoring System Sensor; TPMS Sensor Service Kit; Tire Pressure Sensor; Pressure Sensor; Hardware Kit; Sensor

- Replaces: 68078861AA, 68001696AA, 56053030AB, 68001696AB, 68078861AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 1.1 x 1.9 x 3.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68078861AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2008 Chrysler Pacifica TPMS Sensor Parts and Q&A

- Q: How to Reuse a TPMS Sensor on a Wheel on 2008 Chrysler Pacifica?A: To reuse a TPM sensor on a wheel, replace the original sensor-to-wheel seal (2), metal washer (1) and valve stem nut (3) near the sensor valve stem (6). First, make sure the sensor/valve mounting hole area in the tire is cleaned and that the rest of the wheel's surface is intact. To prevent harming the sensor antenna strap, squeeze the back end of the metal valve stem as you insert the sensor valve into the wheel so that the potted part faces the wheel during installation. Fit the sensor nut (with the pressed-in washer) (3) into place manually, give the sensor housing (2) downward pressure so it matches the wheel's inside shape and then tighten the sensor nut. Holding the sensor steady, tighten the sensor nut to 6.5 Nm (58 in. lbs.) and be careful not to go over 12 Nm (106 in. lbs.), since any extra pressure might cause the sensor to come off the valve stem. Mounting the tire on the wheel should follow the tire changer maker's step-by-step guide, placing the sensor valve (2) 210° series number from the changer's head for rotating tire changers or 210° clockwise from the start of the mounting/dismounting tool (2) for rolling tool tire changers, so that the sensor is above the bead breaker area (3). Use the pressure number given on the placard near the driver's door B-pillar and install the original style and color valve stem cap to keep water from entering the sensor. Set the tire and wheel assembly underneath the vehicle and tighten its wheel mounting nuts (3) to 135 Nm (100 ft. lbs.), afterward lower the vehicle. If you want to enter the new sensor ID, either use TPM-RKE Analyzer or the Special Tool 9936 connected through the Scan Tool on the WCM/SKREEM system. Alternatively, drive the vehicle continuously for 10 minutes at over 15 mph (24 km/h) after it has remained stationary for 20 minutes. If it is not possible to train the sensor, reliance on accurate diagnostic information becomes necessary.