JeepParts

My Garage

My Account

Cart

OEM 2010 Jeep Liberty Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Rod Bearing found

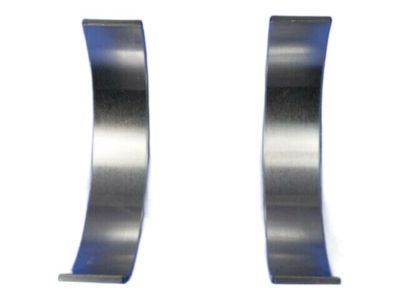

2010 Jeep Liberty Bearings Part Number: 68052222AB

$18.13 MSRP: $26.80You Save: $8.67 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing - Connecting Rod; Engine Connecting Rod Bearing Set; Connecting Rod Bearing Set; Rod Bearing; Bearing Kit Connecting Rod Standard See Note

- Replaces: 5019447AA, 68052222AA

- Item Weight: 0.50 Pounds

- Item Dimensions: 3.9 x 2.6 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 6

- SKU: 68052222AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2010 Jeep Liberty Rod Bearing Parts and Q&A

- Q: How to Inspect and Replace Rod Bearings to Ensure Proper Alignment and Clearance on 2010 Jeep Liberty?A: Check the connecting rod bearings of scorch marks, normal wear patterns, grooving, fatigue and pitting and change any bearing with abnormal wear. Inspect the journals of connecting rod to be clear of scoring, nicks and burrs, isolated, misaligned or bent connecting rods may lead to abnormal wear of pistons, piston rings, cylinder walls, connecting rod bearings and crankshaft connecting rod journals. Where wear marks or damage indicates a misalignment, check the connecting rod to see that each rod is well aligned and that those that do not fall into line be replaced by new rods. Start by cleaning oil on connecting rod journal and grease upper bearing insert and insert it into the connecting rod by centering the same. Install the rod and piston assemblies using the piston ring compressor and Connecting Rod Guides 8507 with the oil slinger slots toward the front of the engine and the short ends of the next to the front of the engine. Install the bottom bearing insert on the bottom side of the bearing cap and ensure that it is dry, and apply to the entire width of the bottom bearing insert where the center of the bearing cap is and this amount of Plastigage must not crumble. Apply the bearing cap and a connecting rod on the journal and use bolts as tight as 27 Nm (20 ft. lbs.) leaving them without turning on crankshaft to prevent smearing on the Plastigage. To get bearing to journal clearance measure the width of the compressed Plastigage without the bearing cap in place compared to acceptable bearing height and width. Provided the clearance is within the proper range of clearance, the Plastigage should be removed and the installation completed; or, in the event that the clearance is too great, the proper bearing set to be used must be identified; also, connecting rod bolts are Torque to Yield and must not be reused. Recheck the Plastigage value and final assembly of bearings should be completed after bearing selection and after installing the correct insert, install a cap on the bearing and tighten connecting rod to 27 Nm (20 ft. lbs.) and a 90deg turn. And, lastly, insert a snug fitting feeler gauge between the connecting rod and the crankshaft journal flange, and in case of the side clearance is not within specifications, replace the connecting rod and adjust the side clearance.