JeepParts

My Garage

My Account

Cart

OEM Chrysler Aspen Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Crankshafts found

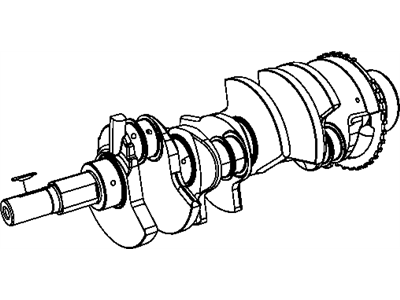

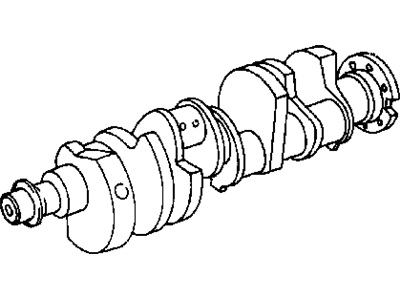

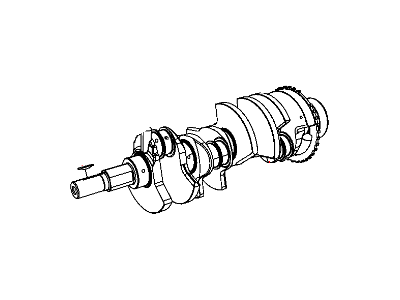

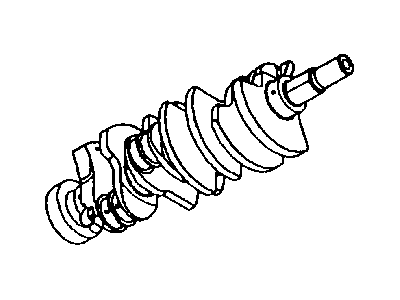

Chrysler Aspen Crankshaft Part Number: 53022286AA

Chrysler Aspen Crankshaft Part Number: 53021302AD

Chrysler Aspen Crankshaft Part Number: 53021302BB

$215.27 MSRP: $317.00You Save: $101.73 (33%)Chrysler Aspen Crankshaft Part Number: 53021387AA

Chrysler Aspen Crankshaft

Choose OEM Crankshaft that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Crankshaft follows strict manufacturing steps to lock in quality and fit. If your Chrysler Aspen matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Aspen parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

In the Chrysler Aspen Crankshaft the company presents a key element which demonstrates both exceptional reliability together with superior performance within its premium series of full-size automobiles. The Chrysler Aspen Crankshaft serves as a fundamental mechanism because it turns the moving piston motion into rotation that enables the transmission to power wheel movement for seamless vehicle operation. With different strength profiles for each variant of engine, the Chrysler Aspen Crankshaft is built from cast iron and forged steel materials to operate various Aspen models running from base 4.7L V8 to top-tier 5.7L Hemi V8 power plants. A well-maintained crankshaft brings increased safety and efficiency to the vehicle by eliminating both abnormal engine vibrations and engine knock. Maintenance operations on the Chrysler Aspen Crankshaft require consistent execution because they extend product life expectancy and preserve operational excellence. The Chrysler Aspen Crankshaft distinguishes itself in the automobile sector because of its exact manufacturing processes and its capacity to enable substantial towing while providing a roomy cabin. The Chrysler car Crankshaft enhances the model lineup and beyond because it performs exceptionally well in fuel economy thanks to the model HEV hybrid system which contributes to making this SUV an attractive choice for drivers who want luxury and performance.

Chrysler Aspen Crankshaft Parts and Q&A

- Q: How is the Crankshaft Installed in an Engine on Chrysler Aspen?A:Before putting in the crankshaft, verify that the bearings have been selected correctly to fit into place. Grease the upper bearings on each side with oil, then make sure you place the crankshaft without harming any bearing surfaces inside the cylinder block. Set the thrust washers in place and coat the bedplate with sealant, where it meets the cylinder block bed, to stop serious oil leaks, provided the area is clean and free of debris. Apply Mopar® Silicone Rubber RTV in the form of a 2.5 mm (0.100 inch) bead to the bedplate surface, cover the crankshaft main bearing journals with new, clean engine oil and slip the bedplate onto the cylinder block. Apply a drop of clean engine oil to the bedplate bolts and fix studs into places three, five and six. Use the specified sequence to install the bedplate retaining bolts, tighten them to 3 Nm (26 in. lbs.) first, then to 54 Nm (40 ft. lbs.), rotate them 90° and end by tightening them to 23 Nm (20 ft. lbs.). Check the end float of the crankshaft, place your connecting rods, adjust their side clearance as appropriate and set the stud in position 10. Install the Oil Pan gasket/windage tray, put the oil pickup tube in with a new O-ring and clamp all fasteners to 28 Nm (20 ft. lbs.). Place the oil pan, then put in all the bolts and tighten them to 15 Nm (11 ft. lbs.) following the proper order. After that, follow instructions to attach the engine to the vehicle.

- Q: How to Safely Extract the Crankshaft from an Engine on Chrysler Aspen?A:You can't take out the crankshaft until you have removed the engine from the vehicle. First, take off the engine, then remove the engine oil pump. Don't disturb the Oil Pan gasket while handling the oil pan, as it stays fixed to the block when you pry out the oil pan. Following this, take out the oil pan, then get rid of the oil pump pickup tube and its gasket or windage tray. Once the bedplate mounting bolts are done, pull them out and mark the position of each stud bolt out of the three that support the bedplate. Get rid of the connecting rods from the crankshaft without damaging the important sealing surface between the bedplate and cylinder block. Treat the bedplate carefully since it holds the lower main bearing halves, because setting them in the wrong order can severely damage the crankshaft. Use the special areas on the bedplate to carefully work your way around it and remove it. Next, remove the crankshaft, making sure not to hurt the housing bearings.