JeepParts

My Garage

My Account

Cart

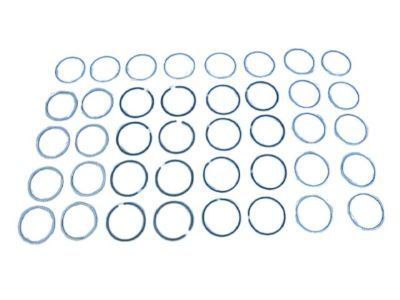

OEM Chrysler Aspen Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Piston Ring Sets found

Chrysler Aspen Piston Rings Part Number: 68031606AA

$44.45 MSRP: $66.45You Save: $22.00 (34%)Ships in 1-2 Business Days

Chrysler Aspen Piston Rings Part Number: 5086002AC

$49.89 MSRP: $63.25You Save: $13.36 (22%)Ships in 1-2 Business Days

Chrysler Aspen Piston Rings Part Number: 5012364AE

Chrysler Aspen Piston Rings Part Number: 68046210AB

$241.33 MSRP: $359.00You Save: $117.67 (33%)

Chrysler Aspen Piston Ring Set

Choose OEM Piston Ring Set that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Piston Ring Set follows strict manufacturing steps to lock in quality and fit. If your Chrysler Aspen matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Aspen parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

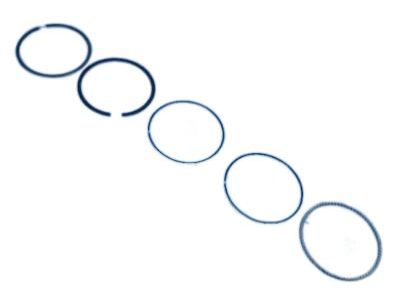

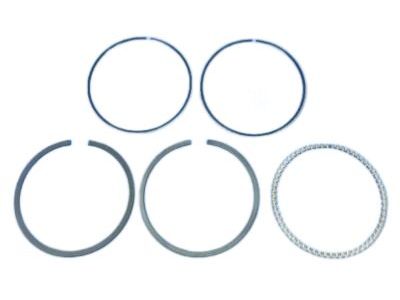

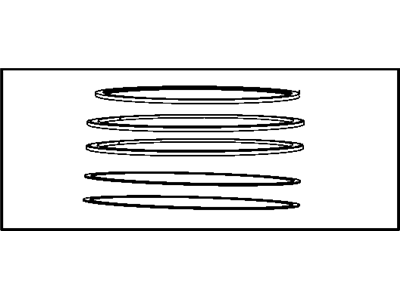

Reliability together with excellent performance distinguishes the Chrysler Aspen Piston Ring Set as it maintains the operational stability of Chrysler Aspen vehicles. The Piston Ring Set delivers efficient sealing of combustion chambers to optimize fuel-air mixture combustion and regulate engine oil consumption while stopping gas escape. Modern advances enable the Chrysler Aspen Piston Ring Set to operate with 1mm top and second rings and 2mm oil control rings which result in reduced friction and better sealing performance. The engine performance along with engine lifespan depends heavily on this component in Chrysler Aspen models with the 4.7L V8 and 5.7L Hemi V8 engines. The heat-resistant coating protects steels and ductile irons that constitute the Chrysler Aspen Piston Ring Set leading to better operational results. The Piston Ring Set enhances engine performance through better sealing ability and oil control thereby simultaneously improving vehicle safety measures. Reliability from the the automaker model Piston Ring Set together with its excellent towing ability and ample cabin space makes the vehicle an outstanding automotive selection. The car Piston Ring Set stands as a core component for vehicle owners because of its performance capabilities and durability which protects safety and keeps driving comfortable throughout the years.

Chrysler Aspen Piston Ring Set Parts and Q&A

- Q: How to Check Clearances and Install a Piston Ring Set on Chrysler Aspen?A:Prior to installing used or new rings, clean the cylinder bore, insert a ring in it and ensure you measure the ring gap when it is set at least 12mm (0.50 inch) from the lowermost part of the cylinder bore. Remove the Piston, square the ring in the box so it's centered, then lower it into place and check each ring with a feeler gauge, changing them if they are not as specified. Clean the walls of the piston ring grooves and check them for damage; then, hold the feeler between the piston ring and the ring groove and replace any ring that doesn't fit properly. Spin the ring on the piston rod to check it rotates freely around the groove. Because the No. 1 and No. 2 piston rings are different, make sure the No. 2 ring has the minor side facing up towards the top of the piston (the side with the manufacturer's I.D. or Dot on it). First is the oil ring expander, then the upper oil ring side rail, the lower oil ring side rail, followed by the No. 2 intermediate piston ring and finally the No. 1 upper piston ring. After installing the oil ring expander, slide one side rail into place between the piston ring and the expander, grip it, push it down and repeat the process for the lower side rail. It is important to use a piston ring installer when you put in both the No. 2 intermediate and No. 1 upper piston rings. Arrange the piston ring end gaps so that the expander ring gap is about 45° away from the sides, not at the piston pin center or in the thrust direction.