JeepParts

My Garage

My Account

Cart

OEM Chrysler Cirrus Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Intake Manifolds found

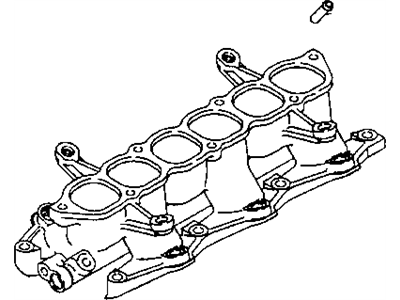

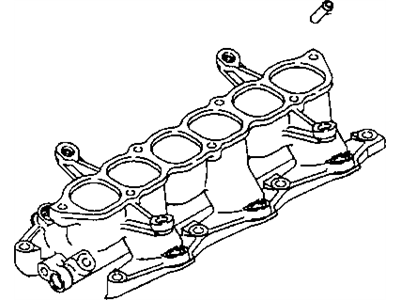

Chrysler Cirrus Intake Manifold Part Number: MD333780

Chrysler Cirrus Intake Manifold Part Number: MD309078

Chrysler Cirrus Intake Manifold Part Number: 4856614AB

Chrysler Cirrus Intake Manifold Part Number: 4792209

Chrysler Cirrus Intake Manifold Part Number: 4792183

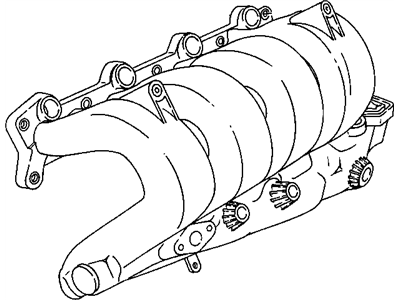

Chrysler Cirrus Intake Manifold

Choose OEM Intake Manifold that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Intake Manifold follows strict manufacturing steps to lock in quality and fit. If your Chrysler Cirrus matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Cirrus parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

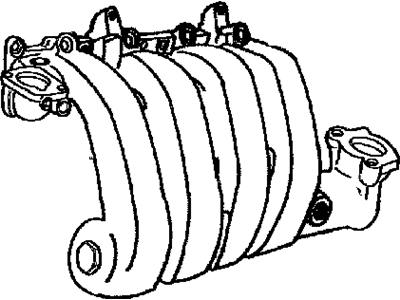

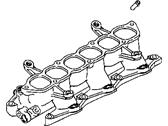

Intake manifold of Chrysler Cirrus automobile is responsible for supplying air or sometimes air fuel mixture to the cylinders in a car to enhance performance of the car engine. This is done by the use of specific designs in the style such as Variable Length Intake manifolds (VLIM), which determines the air volume and boosts power with the use of venturies and other resonators such as Helmholtz. Original Chrysler Cirrus intake manifolds were usually of cast iron or aluminum but now most automobiles uses lightweight composite plastics in their manifolds thus enhancing fuel efficiency and heat management. It often comprises pistons with independent heads linked by Gaskets, Coolants, and probe to measure the operation of an engine.

Chrysler Cirrus Intake Manifold Parts and Q&A

- Q: How to Safely Service and Repair an Intake Manifold on Chrysler Cirrus?A:Always remove any pressure from the fuel system, ensure there is proper ventilation and don't work around anything that could lead to burning or smoking. Take off the negative lead from the auxiliary jumper and remove your Air Inlet Resonator. Take off the quick connect coupled to the Fuel Rail, making sure to cover any hose leaks with towels. Unscrew the attaching screws to remove the fuel rail assembly and cover the holes in the injectors to shield them from contamination so you don't damage the injectors by touching their tips. Disconnect the throttle and speed control cables from the throttle lever and bracket, then remove the wiring connectors for the Idle Air Control (IAC) motor, Throttle Position Sensor (TPS), intake air temperature sensor, leak detection pump and all PCV hoses. Loosen the fasteners at the end of the transaxle which connect to the throttle body support bracket, then take out the transaxle to resting place. Following that, loosen the bolts that hold the EGR Tube to both the valve and intake manifold, throwing out the old gaskets. After taking out the last intake manifold screw, remove the intake manifold. The intake manifold and gasket must be placed and fastened together to 12 Nm (105 in. lbs.) using the proper sequence. Take off the plastic wrap over the Fuel Injector holes, make sure they are clear and snap in the fuel rail assembly, setting the screws at 23 Nm (200 in. lbs.). Examine the quick connect fittings for signs of damage and lubricate the tube with clean oil. Only after that, connect the fuel hose to the fuel rail assembly and make sure it locks in place. Set the throttle body in place and secure it with 22 Nm (200 in. lbs.), then link the transaxle to the throttle body support bracket, tighten the bolt 12 Nm (105 in. lbs.) at the throttle body first, then again at the transaxle. Join the PCV, leak detection pump, air temperature sensor, MAP electrical, vapor canister and brake booster hose connectors. Attach the knock sensor electrical and starter relay connectors to each other after the wiring harness is joined to the intake manifold tab and end by hooking the IAC motor and TPS wiring connectors. Rout the throttle and speed control cables to the bracket and hook each end to the throttle lever. Put new gaskets on the EGR tube and carefully fit it onto the valve and the intake manifold. Tighten the tube fasteners at the EGR Valve to 11 Nm (95 in. lbs.) and then the manifold-side fasteners to the same torque. After all the connections are safe, link the negative terminal to the auxiliary jumper, then use the DRB scan tool to perform the ASD Fuel System Test which will hold the system under pressure for 7 minutes or until the engine is turned off.