JeepParts

My Garage

My Account

Cart

OEM Chrysler PT Cruiser Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Brake Lines found

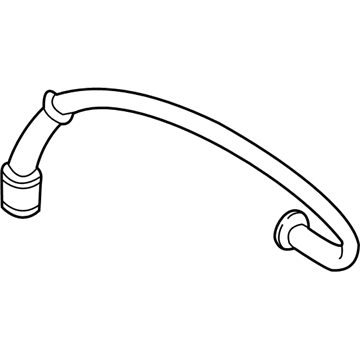

Chrysler PT Cruiser Flex Hose, Rear Passenger Side Part Number: 4860082AF

$93.88 MSRP: $250.00You Save: $156.12 (63%)Ships in 1-2 Business DaysChrysler PT Cruiser Flex Hose, Rear Driver Side Part Number: 4860083AE

$93.88 MSRP: $199.00You Save: $105.12 (53%)Ships in 1-2 Business DaysChrysler PT Cruiser Flex Hose, Front Driver Side Part Number: 4860069AD

$56.09 MSRP: $82.25You Save: $26.16 (32%)Ships in 1-2 Business DaysChrysler PT Cruiser Flex Hose, Rear Driver Side Part Number: 4860081AC

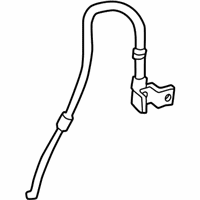

Chrysler PT Cruiser Brake Hose Part Number: 5143270AB

Chrysler PT Cruiser Brake Hose Part Number: 5143271AB

Chrysler PT Cruiser Brake Hose Part Number: 5143267AB

Chrysler PT Cruiser Brake Hose Part Number: 5143268AB

Chrysler PT Cruiser Brake Hose Part Number: 5143273AB

Chrysler PT Cruiser Brake Hose Part Number: 5143274AB

Chrysler PT Cruiser Flex Hose, Rear Driver Side Part Number: 5085527AD

Chrysler PT Cruiser Flex Hose, Rear Driver Side Part Number: 4860081AE

| Page 1 of 2 |Next >

1-20 of 22 Results

Chrysler PT Cruiser Brake Line

Choose OEM Brake Line that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Brake Line follows strict manufacturing steps to lock in quality and fit. If your Chrysler PT Cruiser matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine PT Cruiser parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Brake Line in Chrysler PT Cruiser involves the path through which the brake fluid is supplied to the brake caliper pistons so as to ensure that hydraulic brakes in the automobile are effectively applied. Metal brake lines also give way to corrosion and impact and this is followed by the formation of fluid leakage and loss of hydraulic pressure. Brake hoses tend to wear out physically and mechanically which has a possibility of damaging the brakes. When it is time for replacement there are pre bent brake line kits and direct replacement brake hoses in the market with reasonable corrosion protection along with the right fittings for complete replacement. Converting to stainless steel braided brake lines can help in enhancing the brake pedal response and especially for those special occasions when you are behind the wheel on the race track.

Chrysler PT Cruiser Brake Line Parts and Q&A

- Q: Are Brake Lines Unique for Each Brake and Why Choose Mopar Replacements on Chrysler PT Cruiser?A:Because brake hoses are different for every brake system, always choose replacement brake hoses from Mopar to guarantee quality, accurate length and strong resistance to fatigue. Clean any parts that attach hoses and tubes, get rid of nicks and burrs and then pair new copper washers on the banjo bolt connectors. Tighten everything to their recommended torque levels. To avoid twisting the brake hose when installing, connect the flexible front hydraulic brake hose's banjo fitting to the disc Brake Caliper, next join the brake tubing to the hose and only after completion, tighten the fittings to the required torque. For cars with rear drum brakes, first attach the rear brake hose to the Wheel Cylinder, then fasten the brackets to the axle, attach the hose loosely to the steel tube from the master cylinder and tighten the tube nut at each end. For cars with rear disc brakes, link the brake hose banjo fitting to the caliper first, then secure the brackets to the axle, next connect the hose to the steel tube from the master cylinder and finish by tightening the tube nut at both ends of the brake hose. Replace with only 4.75 mm (3/16 inch) double wall steel brake lines featuring Nygal coating and their special nut and do not allow any tubing to touch sharp edges, moving parts or hot places, then be sure all tubes are secured with the suggested clips.

- Q: How Frequently Should Brake Lines Be Inspected for Damage and What Conditions Need Checking on Chrysler PT Cruiser?A:Brake tubes should be checked periodically to see if they are damaged or touching anything that is either moving or very hot. Rubber hoses are used at both the front and rear wheel brakes and checking them should be done during any brake service and every 12,000 km (7,500 miles) or 12 months-whichever appears sooner. It's important to review hydraulic brake hoses for any surface cracks, scratches or worn sections. A burst happening due to damaged hose cover usually occurs as the casing is now exposed. Therefore, this should be replaced immediately. If suspension improperly installed, twisting may occur and influence the wheel, tire or chassis.