JeepParts

My Garage

My Account

Cart

OEM Dodge Challenger Fuel Pump

Gas Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Fuel Pumps found

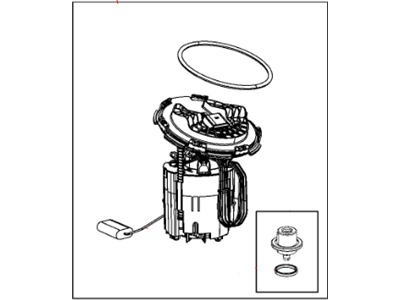

Dodge Challenger Module - Fuel Pump/Level Unit Part Number: 68367534AC

$325.17 MSRP: $484.00You Save: $158.83 (33%)Dodge Challenger Fuel Pump Part Number: 4581410AE

$231.35 MSRP: $319.00You Save: $87.65 (28%)Dodge Challenger Fuel Pump Part Number: 68586130AA

$313.84 MSRP: $462.00You Save: $148.16 (33%)Dodge Challenger Fuel Pump Part Number: 68399003AB

$752.51 MSRP: $1140.00You Save: $387.49 (34%)Ships in 1-2 Business DaysDodge Challenger Package Part - Pickup / Level Unit Part Number: 68643661AB

$766.87 MSRP: $1180.00You Save: $413.13 (36%)Ships in 1-2 Business DaysDodge Challenger Auxiliary Pump Part Number: 68586131AB

$206.21 MSRP: $304.00You Save: $97.79 (33%)Ships in 1-2 Business DaysDodge Challenger Fuel Pump Part Number: 68586450AA

$294.58 MSRP: $434.00You Save: $139.42 (33%)Dodge Challenger Fuel Pump Part Number: 68643783AA

$258.32 MSRP: $383.00You Save: $124.68 (33%)Ships in 1-2 Business DaysDodge Challenger Module - Fuel Pump/Level Unit Part Number: 68445257AB

$313.84 MSRP: $469.00You Save: $155.16 (34%)Dodge Challenger Module - Pickup / Level Unit Part Number: 68494735AB

$236.80 MSRP: $348.00You Save: $111.20 (32%)Ships in 1-2 Business DaysDodge Challenger Module - Fuel Pump/Level Unit Part Number: 68643777AB

$403.04 MSRP: $587.00You Save: $183.96 (32%)Dodge Challenger Fuel Pump Part Number: 68258753AG

$1095.06 MSRP: $1675.00You Save: $579.94 (35%)

Dodge Challenger Fuel Pump Part Number: 68258756AD

$516.40 MSRP: $754.00You Save: $237.60 (32%)

Dodge Challenger Fuel Pump, Passenger Side Part Number: 5136023AF

$313.84 MSRP: $467.00You Save: $153.16 (33%)Dodge Challenger Module - Fuel Pump/Level Unit Part Number: 68367540AB

$399.61 MSRP: $587.00You Save: $187.39 (32%)Dodge Challenger Module - Fuel Pump/Level Unit Part Number: 68102700AE

$420.22 MSRP: $612.00You Save: $191.78 (32%)Dodge Challenger Module - Fuel Pump/Level Unit Part Number: 5136022AM

$438.54 MSRP: $639.00You Save: $200.46 (32%)Dodge Challenger Module - Fuel Pump/Level Unit Part Number: 68103913AF

$424.80 MSRP: $619.00You Save: $194.20 (32%)

Dodge Challenger Fuel Pump

Choose OEM Fuel Pump that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Fuel Pump follows strict manufacturing steps to lock in quality and fit. If your Dodge Challenger matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Challenger parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

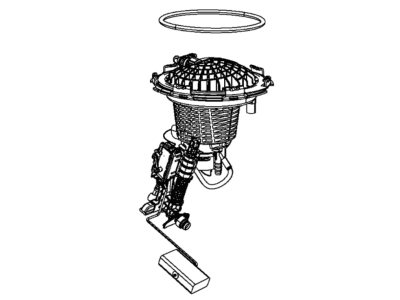

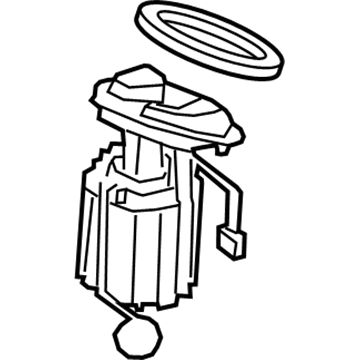

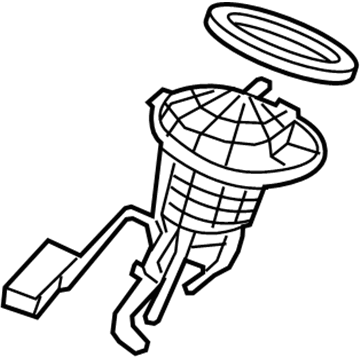

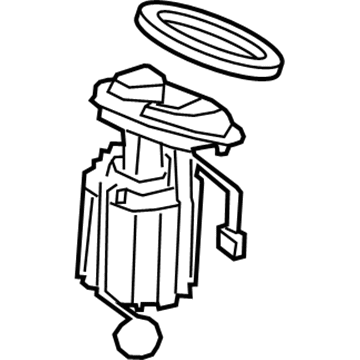

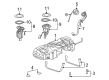

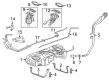

The Fuel Pump of Dodge Challenger cars is instrumental in supplying fuel to the engine utilizing either a carburetor or a fuel injection device. Electric pumps are used in fuel injection systems while those mechanical are used in carburetor systems. High-pressure pumps mechanical are driven by the camshaft and have the float valve which will prevent over-pumping. Electric pumps that are installed within the fuel tank are higher in pressures as well as efficacy controlled by the electronic control units for safe and efficient fuel pump control. Application of various configurations in high-pressure fuel pumps in today's engines aims at delivering constant pressure to the engine in an attempt to have better control on the engine performance as well as rate of pollutions emitted.

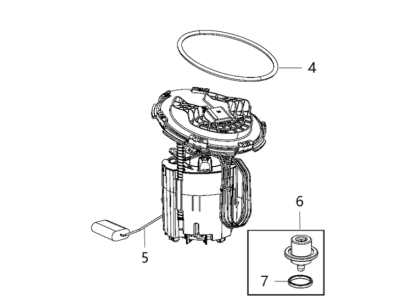

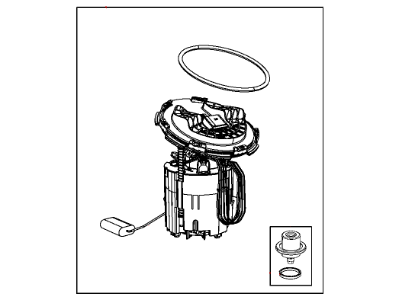

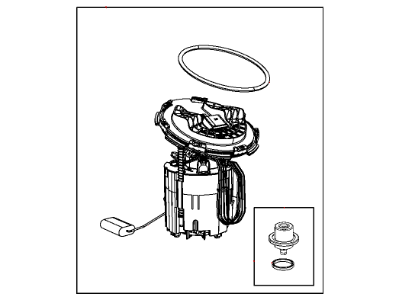

Dodge Challenger Fuel Pump Parts and Q&A

- Q: How to Remove and Service the Fuel Pump Module on Dodge Challenger?A:Always ensure the fuel system is depressurized before starting to maintain safety, as it remains under high pressure even when idle and will remain under pressure. Choose clothes that protect you and remember to wear eye protection, while doing the work in a well-ventilated and spark-free area. Let's begin by disconnecting the fuel pressure. When the fuel pump module or fuel level sensor fails and the level is incorrect, first empty the fuel tank while it is elevated so excess fuel does not come out. After you take off the negative Battery Cable, remove the rear lower Seat Cushion and pull the foam pad centered on the fuel pump module area. Open the access cover on the left side, take out the electrical connector and be sure to see where the arrow is positioned for later placement. Shake compressed air on the area surrounding the fuel tank access to clean it and only then mark the correct position for installing the fuel pump module. To remove the lock-ring with a 1/2 inch drive breaker bar, use lock-ring remover/installer 9340 and lift the fuel pump module afterwards to get to the lower connections. Disconnect the electrical connectors on top of the module, remove the upper strip and push the quick release tab to disconnect the fuel supply line. Don't let any fuel run into the inside of the vehicle by first taking out the lower plug and fuel return tubes. Tip the pump module and let the remaining liquid fuel escape before taking the module out and removing and replacing the rubber O-ring seal which should be thrown away.